供应链下的多级存货管理【外文翻译】

- 格式:pdf

- 大小:177.67 KB

- 文档页数:11

供应链VMI模式下的库存管理优化随着全球化的不断加速,企业间的竞争愈加激烈。

在这个竞争激烈的市场环境下,企业需要不断地提高业务流程和管控能力,以取得更好的市场优势。

在此情况下,供应链VMI模式成为了企业优化库存管理的一种有效方式。

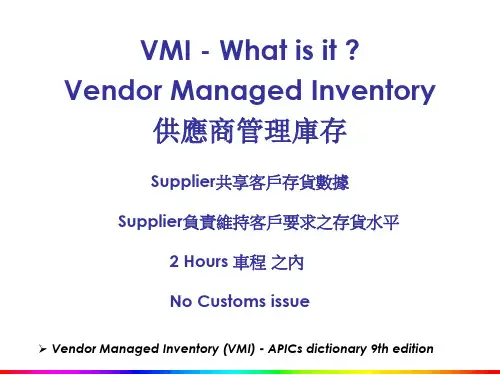

一、什么是VMI模式?VMI全称为Vendor Management Inventory,即供应商库存管理。

简单来说,是指供应商能够直接参与到,帮助客户对库存进行控制与管理的一种模式。

在VMI模式下,供应商掌握着客户的库存信息,可以根据客户的需求直接进行发货操作,从而能够更好地实现供需的平衡和优化。

二、 VMI模式的优势1. 降低库存成本在传统的库存管理模式中,客户需要时刻关注库存的数量和质量,以确保生产的正常和顺畅。

然而这一过程中,会引起过度采购、物料过多甚至保质期过短等问题,导致客户的库存成本不断上升。

而在VMI模式下,供应商负责客户的库存管理,客户无需再过多地关注库存的数量和质量,从而能够实现库存成本的降低。

2. 压缩库存周期在传统的库存管理体系中,客户需提前预定所需物料,供应商再进行生产、发货等操作后,才能将物料到达客户仓库。

这一过程需要较长的时间,会大大延长库存周期。

而在VMI模式下,供应商了解客户需求后,可以依据当时实际库存情况,立刻为客户发货,从而将库存周期大幅压缩。

3. 提高企业竞争力库存管理与采购效率直接关系到企业生产效率和竞争力。

随着供应链VMI模式不断提高工业运作的效率和生产的灵活性,更加适应市场变化。

在供应链VMI模式下,企业可以实现快速响应市场需求,提高管理水平和生产效率,从而为企业带来更多的竞争优势。

三、基于VMI模式下的库存管理优化在VMI模式下,库存管理的重点在于供应商和客户之间的合作。

针对不同的采购需求和库存料号等问题,可以采取以下具体措施实现库存优化:1. 合理分析产品分类针对已有产品,可以根据分类规则与标准制定一份产品分类表,将现有库存品种归类,并按照供应商和客户之间的物料需求比例分配库存物料,从而优化库存管理。

多级库存优化管理——基础库存的最优化配置是企业重要的业务功能。

低库存带来的制造、分销或零售运作上的优势表现为营运资本的永久性减少、更高的销售量和客户满意度。

正如Forrester Research在近期的一份报告上指出的那样,增强库存周转的能力是企业导致成功与失败的主要因素之一。

管理库存是企业的艰巨任务,特别是那些在多个地方都拥有好几万种商品的企业。

当这些商品处于企业分销网络的不同层级时,这种挑战就更为突出了。

在这种多层级网络中,新产品出货后首先储存在地区或者中心机构中。

这些中心机构是面对客户端的内部供应商。

对于零售渠道和大型分销商和制造商而言,这是一种普遍的分销模式。

比如,大型的医药批发商的分销网络包括一个地区性分销中心(RDC)和超过30种的前向分销中心(DC)。

另一种汽车零部件和设备的全国性零售商管理了超过2500万库存单元(SKU),这些库存单元跨越了10个DC和超过900家店。

最后家具构件的全球制造商/分销商在将产成品运送到全世界15个当地DC前,首先从位于工厂附近的欧洲DC装货。

然后由这15个DC服务终端的顾客。

与单层网络相比,在多层级网络中管理库存都存在很多缺陷。

缺陷之一是不能实现真正的网络库存优化,因为补货战略通常是应用于同一级的,而没有考虑对其他层级的冲击。

当你仅仅处理一个单一层级时,通常缺乏对整个需求链上的库存使用状况的系统性看法。

另一大缺陷是将上一层级的补货决策建立在华而不实的需求预测基础上。

而这些缺陷能产生出各种相关的负结果,包括:●网络以多余安全库存的形式保留了过多的库存;●即使网络中存在充足的库存,终端顾客服务缺陷仍然发生;●当层级之间的服务超过可接受的范围时,面对客户的供应点发生令人不快的存货短缺;●外部供应商提供不可靠的业绩信息,因为他们接收了令人不满意的需求指示;●目光短浅的内部产品配置决策是非常有限的。

本文将会考察解决多级网络中管理库存问题的两种可供选择的方法,此外,文章也会提出在满足所有客户服务目标的同时,最小化各层级库存的最佳方法。

外文翻译--- 供应链管理下的库存控制在供应链管理环境下,库存控制仍然存在一些问题,需要企业及时解决。

主要问题包括以下几个方面:1.信息不对称在供应链中,不同企业之间的信息不对称问题比较严重,导致企业难以准确预测市场需求,从而影响库存控制的效果。

2.订单不稳定供应链中的订单不稳定性也是影响库存控制的重要因素之一。

订单不稳定会导致企业难以确定库存水平,从而影响供应链整体绩效。

3.物流配送问题物流配送问题也是影响库存控制的重要因素之一。

物流配送不畅会导致库存积压,增加企业的库存成本。

4.缺乏协调供应链中各个企业之间缺乏协调也是影响库存控制的重要因素之一。

缺乏协调会导致企业之间的库存信息不同步,从而影响供应链整体绩效。

为了解决这些问题,企业需要采取一系列措施,如加强信息共享、优化订单管理、完善物流配送体系、建立协调机制等,以提高供应链整体绩效和库存控制的效果。

尽管从宏观角度来看,供应链管理环境下的库存控制比传统管理更具优势,但实际操作中,由于每个企业对供应链管理的理解存在差异,存在利益冲突等问题,导致实际运用时也会出现许多问题。

其中,主要存在以下几个方面的问题:1.各企业缺乏供应链管理的整体观念,导致各自为政的行为降低了供应链整体效率。

2.交货状态数据不准确,导致客户不满和供应链中某些企业增加库存量。

3.信息传递系统低效率,导致延迟和不准确的信息,影响库存量的精确度和短期生产计划的实施。

4.缺乏合作与协调性,组织障碍是库存增加的一个重要因素。

5.产品的过程设计没有考虑供应链上库存的影响,导致成本效益被库存成本抵消,引进新产品时也会遇到问题。

因此,在供应链管理环境下,需要制定合适的库存控制策略,包括建立整体观念,提高信息传递效率,加强合作与协调性,考虑库存影响的产品设计等措施,以提高供应链整体效率。

针对库存管理问题,我们推出以下策略:1.供应商管理库存策略:VMI(Vendor Managed Inventory)库存管理模式。

Review of Research on Inventory Management in theEnvironment of Supply ChainHE Cai-hong ,ZHOU Xian-cheng(Finance School,Hunan University of Commerce,Changsha,Hunan 410205;School of Compute and Electronic Engineering,Hunan University of Commerce,Changsha,Hunan 410205Abstract :With the spread and application of supply chain,the research on inventory management in the environment of supply chain has attracted significant attentions from the academic world.Present research is reviewed on inventory management in the environment of supply chain,including two aspects of inventory model and inventory management strategy.In the end,the paper discusses the future research tendency.Key words :supply chain management;inventory management;review供应链环境下库存管理研究综述贺彩虹,周鲜成(湖南商学院财务处,湖南长沙410205;湖南商学院计算机与电子工程学院,湖南长沙410205摘要:随着供应链管理的推广和应用,供应链环境下的库存管理研究得到了学者们的广泛关注。

毕业设计(论文)外文资料翻译外文出处:The ABCs of Supply Chain (用外文写)Management附件:1.外文资料翻译译文;2.外文原文。

附件1:外文资料翻译译文供应链管理ABC1.什么是供应链管理供应链是一种关于整合的科学和艺术,它主要探究提高企业采购生产商品所需的原材料、生产商品,并把它供应给最终顾客的效率的途径。

以下是供应链管理的五个基本组成模块:计划--它是供应链的战略层面。

企业需要有一个控制所有资源的战略以满足客户对产品或服务的需求。

计划的核心是建立一套机制去监控整条供应链以便使它能有效运作:低成本、高品质配送和增值客户服务。

该模块连结着供应链的作业与营运目标,主要包括需求/供给规划(Demand/Supply Planning)与规划基础建设(infrastructure)两项活动,对所有采购运筹流程、制造运筹流程与配送运筹流程进行规划与控制。

需求/供给规划活动包含了评估企业整体产能与资源、总体需求规划以及针对产品与配销管道,进行存货规划、配送规划、制造规划、物料及产能的规划。

规划基础建设管理包含了自制或外包决策的制定、供应链的架构设计、长期产能与资源规划、企业规划、产品生命周期的决定、新旧产品线规划与产品线的管理等。

采购—选择供给你提供用来生产产品或服务的原材料或服务的供应商。

和供应商建立一套价格、供应、支付过程的体系,创造一种机制以监控此过程、改善供应商关系。

理顺此过程以管理供应商交付的原材料库存或服务,其中包括收货、出货、检验、中转和批准支付。

此模块有采购作业与采购基础建设两项管理活动,其目的是描述一般的采购作业与采购管理流程。

采购作业包含了寻找供货商、收料、进料品检、拒收与发料作业。

采购基础建设的管理包含了供货商评估、采购、运输管理、采购品质管理、采购合约管理、付款条件管理、采购零组件的规格制定。

制造—这是制造步骤。

计划这些必需的活动:生产、测试、包装、预出货。

基于供应链环境的多级库存优化管理研究基于供应链环境的多级库存优化管理研究1. 引言随着全球化经济的发展和供应链管理的日益重要,多级库存管理在现代供应链中扮演着至关重要的角色。

随着市场竞争加剧,企业需要寻求有效的库存管理方法来降低库存成本,提高客户满意度,并确保供应链的可靠性和灵活性。

因此,本文将研究基于供应链环境的多级库存优化管理,旨在提供有效的库存管理策略,以满足供需平衡和经济效益的要求。

2. 多级库存的定义和特点多级库存是指在供应链中各级节点上的库存,这些节点包括供应商、生产商、分销商和最终客户等。

多级库存的管理涉及到从供应链的源头到终端,以及供应链内部的库存转移和协同。

多级库存管理具有以下特点:首先,在供应链中的每个节点上都存在库存,这些节点之间的关系和交互会对库存管理产生影响。

因此,多级库存管理需要考虑不同节点之间的信息传递、协作和协调。

其次,多级库存管理需要解决不同节点之间的信息不对称和延迟的问题。

供应链中的每个节点都有不同的库存需求和预测,但这些信息通常存在不确定性和时滞性。

因此,多级库存管理需要考虑如何准确地收集、分析和利用节点之间的信息,以实现优化的库存管理。

最后,供应链中的多级库存管理需要考虑不同节点之间的协同和协调。

在实际情况下,供应链中的库存决策往往是分散的,各个节点往往只看到局部的库存需求和预测。

因此,多级库存管理需要确保不同节点之间的协同和协调,以实现整体的供需平衡和经济效益。

3. 多级库存优化的挑战实现基于供应链环境的多级库存优化管理面临着许多挑战,包括库存需求的不确定性、供应链节点之间的信息流通和协调以及库存管理策略的决策问题等。

首先,库存需求的不确定性是多级库存优化管理的主要挑战之一。

供应链中的库存需求受到市场需求、产品周期和季节性等因素的影响,这些因素往往难以准确预测。

因此,如何处理库存需求的不确定性,实现供需平衡和库存成本的最优化是多级库存优化管理的重要问题。

供应链下的多级存货管理外文文献1、IntroductionIn today's globalized and interconnected business environment, supply chain management has become an essential component of enterprise success. One of the key elements of supply chain management is inventory management, which involves the effective management of inventory levels across multiple tiers of the supply chain. This article examines the concept of multi-level inventory management within the context of supply chain management and explores relevant literature from foreign sources.2、Supply Chain Management and Inventory ManagementSupply chain management involves the integration and coordination of various activities across all levels of a supply chain, from suppliers to manufacturers, distributors, and consumers. Inventory management, specifically, refers to the effective management of inventory levels in order to meet demand while minimizing costs and risks. It involves theidentification of demand patterns, the determination of appropriate inventory levels, and the implementation of policies and procedures to ensure that inventory is rotated and utilized effectively.3、Multi-Level Inventory Management in the Supply ChainMulti-level inventory management refers to the management of inventory across multiple tiers or levels within a supply chain. It involves the coordination and synchronization of inventory levels across different stages of the supply chain to ensure efficient flow of goods and materials. By managing inventory at multiple levels simultaneously, enterprises can optimize overall inventory levels while ensuring that each tier of the supply chain is able to meet demand.4、Foreign Literature Review on Multi-Level Inventory ManagementA review of foreign literature on multi-level inventory management reveals a growing body of research on this topic. Studies have focused on various aspects of multi-levelinventory management, including demand forecasting, inventory policies, and supply chain coordination. Notably, research has shown that multi-level inventory management can significantly improve overall supply chain performance by reducing costs and increasing efficiency.5、ConclusionThe concept of multi-level inventory management within the context of supply chain management has gained significant attention in recent years. A review of foreign literature suggests that effective multi-level inventory management can lead to significant improvements in overall supply chain performance by optimizing inventory levels across different stages of the supply chain. Enterprises that adopt multi-level inventory management strategies can expect to achieve cost savings, increased efficiency, and a more robust supply chain overall.6、Recommendations for Future ResearchDespite the growing body of research on multi-level inventorymanagement, there are still several areas that require further exploration. Future research could focus on developing more advanced demand forecasting techniques to improve accuracy and reduce demand uncertnty. Additionally, studies could investigate novel inventory policies and strategies that can further optimize inventory levels across different tiers of the supply chn. Finally, research could also examine the role of technology in supporting multi-level inventory management, including the use of artificial intelligence, big data analytics, and other emerging technologies.供应链管理外文翻译供应链管理是一种全面的管理方法,旨在优化供应链的运作,提高效率和竞争力。

外文翻译inventory managementMaterial Source: spring link Author: Floyd D. Hedrick“Inventory” to many small business owners is one of the more visible and tangible aspects of doing business. Raw materials, goods in process and finished goods all represent various forms of inventory. Each type represents money Tied up until the inventory leaves the company as purchased products. Likewise, merchandise stocks in a retail store contribute to profits only when their sale puts money into the cash register. In a literal sense, inventory refers lo stocks of anything necessary lo do business. These stocks represent a large portion of the business investment and must be well managed in order to maximize profils. In facl, many small businesses cannot absorb the types of losses arising from poor inventory management. Unless invenlories are controlled, they are unreliable, inefficient and costly.SUCCESSFUL INVENTORY MANAGEMENTSuccessful inventory management involves balancing the costs of inventory with the benefits of inventory. Many small business owners fail to appreciate fully the true costs of carrying inventory, which include not only direct costs of storage, insurance and taxes, but also the cost of money tied up in inventory. This fine line between keeping too much inventory and not enough is not the manager's only concern. Others include: Maintaining a wide assortment of stock •• but not spreading the rapidly moving ones too thin: Increasing inventory turnover - but not sacrificing the service level: Keeping slock low - but not sacrificing service or performance. Obtaining lower prices by making volume purchases -- but not ending up with slow-moving invenlory: and having an adequate invemory on hand - but not gelling caught with obsolete items.The degree of success in addressing these concerns is easier to gauge for some than for others. For example, computing the inventory turnover ratio is a simple measure of managerial performance. This value gives a rough guideline by which managers can set goals and evaluate performance, but it must be realized that the turnover rate varies with the function ol' inventory, the type of business and how the ratio is calculated (whether on sales or cost of goods sold). Average inventory turnover ratios for individual industries can be obtained from trade associations.One of the most important aspects of inventory control is to have the items in stock at the moment they are needed. This includes going into the market to buy the goods early enough to ensure delivery at the proper time. Thus, buying requires advance planning to determine inventory needs for each time period and then making the commitments without procrastination.For retailers, planning ahead is very crucial. Since they offer new items for sale months before the actual calendar date for the beginning of the new season, it is imperative that buying plans be formulated, early enough to allow for intelligent buying without any last minute panic purchases. The main reason for this early offering for sale of new items is that the retailer regards the calendar date for the beginning of Ihe new season as the merchandise date for ihe end of the old season. For example, many retailers view March 21 as the end of the spring season, June 21 as the end of summer and December 21 as Ihe end of winter.Part of your purchasing plan must include accounting for the depletion of the inventory. Before a decision can be made as to the level of inventory lo order, you must determine how long the inventory you have in stock will last.For instance, a retail firm must formulate a plan to ensure the sale of the greatest number of units. Likewise, a manufacturing business must formulate a plan to ensure enough inventory is on hand for production of a finished product.In summary, the purchasing plan detail: When commitments should be placed: When the first delivery should be received; When the inventory should be peaked; When reorders should no longer be placed: and When the item should no longer be in stock.Well planned purchases affect the price, delivery and availability of products for sale.CONTROLLING YOUR INVENTORYTo maintain an in-stock position of wanted items and to dispose of unwanted items, it is necessary to establish adequate controls over inventory on order and inventory in stock. There are several proven methods for inventory control. They are listed below, from simplest to most complex. Visual control enables the manager to examine the inventory visually to determine if additional inventory is required. In very small businesses where this method is used, records may not be needed at all or only for slow moving or expensive items. Tickler control enables the manager tophysically count a small portion of the inventory each day so that each segment of the inventory is counted every so many days on a regular basis. Click sheet control enables the manager to record the item as il is used on a sheel of paper. Such information is then used for reorder purposes. Stub control (used by retailers) enables the manager to retain a portion of the price ticket when the item is sold. The manager can then use the stub to record the item that was sold.As a business grows, it may find a need for a more sophisticated and technical form of inventory control. Today, the use of computer systems to control inventory is far more feasible for small business than ever before, both through the widespread existence of computer service organizations and the decreasing cost of small-sized computers. Often the justification for such a computer-based system is enhanced by the fact that company accounting and billing procedures can also be handled on the computer.Point-of-sale terminals relay information on each item used or sold. The manager receives information printouts at regular intervals for review and action.Off-line point-of-sale terminals relay information directly to the supplier's computer who uses the information to ship additional items automatically to the buyer/inventory manager.The final method for inventory control is done by an outside agency. A manufacturer's representative visits the large retailer on a scheduled basis, takes Ihe stock count and writes the reorder. Unwanted merchandise is removed from stock and returned lo Ihe manufacturer Ihrough a predetermined, authorized procedure.A principal goal for many of the methods described above is to determine the minimum possible annual cost of ordering and stocking each item. Two major control values are used: 1) the order quantity, that is, the size and frequency of order: and 2) the reorder point, that is, the minimum stock level at which additional quantities are ordered. The Economic Order Quantity (EOQ) formula is one widely used method of computing the minimum annual cost for ordering and stocking each item. The EOQ computation takes into account the cost of placing an order, the annual sales rate, the unit cost、and the cost of carrying invenlory. Many books on management practices describe the EOQ model in detail.DEVELOPMENTS IN INVENTORY MANAGEMENTIn recenl years, two approaches have had a major inipacl on inventory management: Material Requirements Planning (MRP) and Just-In-Time (JIT andKanban). Their application is primarily within manufacturing but suppliers might find new requirements placed on them and sometimes buyers of manufactured items will experience a difference in delivery.Material requirements planning is basically an information system in which sales arc converted dircctly into loads on the facility by sub-unit and time period. Materials are scheduled more closely, thereby reducing inventories, and delivery times become shorter and more predictable. Its primary use is with products composed of many components. MRP systems are practical for smaller firms. The computer system is only one part of the total project which is usually long-term, taking one to three years lo develop.Just-in-time inventory management is an approach which works to eliminate inventories rather than optimize them. The inventory of raw materials and work-in-process falls to that needed in a single day. This is accomplished by reducing set-up times and lead times so that small lots may be ordered. Suppliers may have to make several deliveries a day or move close to the user plants to support this plan.TIPS FOR BETTER INVENTORY MANAGEMENTAt time of delivery. Verify count -- Make sure you are receiving as many cartons as arc listed on the delivery rcccipt. Carefully examine cach carton for visible damage ~ If damage is visible, note it on the delivery receipt and have Ihe driver sign your copy. After delivery, immediately open all cartons and inspcct for merchandise damage.When damage is discovered: Retain damaged items - All damaged materials must be held at Ihe point received. Call carrier to report damage and request inspection. Confirm call in writing—This is not mandatory but it is one way to protect yourself.Carrier inspection of damaged items. Have all damaged items in the receiving area - Make certain the damaged items have not moved from the receiving area prior to inspection by carrier. After carrier /inspector prepares damage report, carefully read before signing.After inspeclion: Keep damaged materials—Damaged materials should not be used or disposed of without permission by the carrier. Do not return damaged items without wrillen aulhorization from shipper/supplier.SPECIAL TIPS FOR MANUFACTURERSIf you are in the business of bidding, specifications play a very important role. In writing specifications, the following elements should be considered. Do not request features or quality thai are not necessary for the items' intended use. Include full descriptions of any tesling lo be performed. Include procedures for adding optional items. Describe the quality of the items in clear terms.The following aclions can help save money when you are slocking inventory: Substitution of less costly materials without impairing required quality: Improvement in quality or changes in specifications that would lead to savings in process time or other operating savings; Developing new sources of supply; Greater use of bulk shipments; Quantity savings due to large volume, through consideration of economic order quantity: A reduction in unit prices due to negotiations:Initiating make-or-buy studies: Application of new purchasing techniques; Using competition along with price, service and delivery when making the purchase selection decision.译文存货管理资料来源:s p r i n g l i n k作者•:F l o y d D. H e d r i c k “存货”对于许多小企业来说是一种更容易看到和有形的资产。

本科毕业论文(设计)外文翻译原文:Multi-echelon inventory management in supply chains Historically, the echelons of the supply chain, warehouse, distributors, retailers, etc., have been managed independently, buffered by large inventories. Increasing competitive pressures and market globalization are forcing firms to develop supply chains that can quickly respond to customer needs. To remain competitive and decrease inventory, these firms must use multi-echelon inventory management interactively, while reducing operating costs and improving customer service.Supply chain management (SCM) is an integrative approach for planning and control of materials and information flows with suppliers and customers, as well as between different functions within a company. This area has drawn considerable attention in recent years and is seen as a tool that provides competitive power .SCM is a set of approaches to integrate suppliers, manufacturers, warehouses, and stores efficiently, so that merchandise is produced and distributed at right quantities, to the right locations and at the right time, in order to minimize system-wide costs while satisfying service-level requirements .So the supply chain consists of various members or stages. A supply chain is a dynamic, stochastic, and complex system that might involve hundreds of participants.Inventory usually represents from 20 to 60 per cent of the total assets of manufacturing firms. Therefore, inventory management policies prove critical in determining the profit of such firms. Inventory management is, to a greater extent, relevant when a whole supply chain (SC), namely a network of procurement, transformation, and delivering firms, is considered. Inventory management is indeed a major issue in SCM, i.e. an approach that addresses SC issues under an integrated perspective.Inventories exist throughout the SC in various forms for various reasons. Thelack of a coordinated inventory management throughout the SC often causes the bullwhip effect, namely an amplification of demand variability moving towards the upstream stages. This causes excessive inventory investments, lost revenues, misguided capacity plans, ineffective transportation, missed production schedules,and poor customer service.Many scholars have studied these problems, as well as emphasized the need of integration among SC stages, to make the chain effectively and efficiently satisfy customer requests (e.g. reference). Beside the integration issue, uncertainty has to be dealt with in order to define an effective SC inventory policy. In addition to the uncertainty on supply (e.g. lead times) and demand, information delays associated with the manufacturing and distribution processes characterize SCs.Inventory management in multi-echelon SCs is an important issue, because thereare many elements that have to coordinate with each other. They must also arrangetheir inventories to coordinate. There are many factors that complicate successful inventory management, e.g. uncertain demands, lead times, production times, product prices, costs, etc., especially the uncertainty in demand and lead times where the inventory cannot be managed between echelons optimally.Most manufacturing enterprises are organized into networks of manufacturingand distribution sites that procure raw material, process them into finished goods, and distribute the finish goods to customers. The terms ‘multi-echelon’ or ‘multilevel‘production/distribution networks are also synonymous with such networks(or SC), when an item moves through more than one step before reaching the final customer. Inventories exist throughout the SC in various forms for various reasons. Atany manufacturing point, they may exist as raw materials, work in progress, or finished goods. They exist at the distribution warehouses, and they exist in-transit, or‘in the pipeline’, on each path linking these facilities.Manufacturers procure raw material from suppliers and process them into finished goods, sell the finished goods to distributors, and then to retail and/or customers. When an item moves through more than one stage before reaching thefinal customer, it forms a ‘multi-echelon’ inventory system. The echelon stock of a stock point equals all stock at this stock point, plus in-transit to or on-hand at any of its downstream stock points, minus the backorders at its downstream stock points.The analysis of multi-echelon inventory systems that pervades the business world has a long history. Multi-echelon inventory systems are widely employed to distribute products to customers over extensive geographical areas. Given the importance of these systems, many researchers have studied their operating characteristics under a variety of conditions and assumptions. Since the development of the economic order quantity (EOQ) formula by Harris (1913), researchers and practitioners have been actively concerned with the analysis and modeling of inventory systems under different operating parameters and modeling assumptions .Research on multi-echelon inventory models has gained importance over the last decade mainly because integrated control of SCs consisting of several processing and distribution stages has become feasible through modern information technology. Clark and Scarf were the first to study the two-echelon inventory model. They proved the optimality of a base-stock policy for the pure-serial inventory system and developed an efficient decomposing method to compute the optimal base-stock ordering policy. Bessler and Veinott extended the Clark and Scarf model to include general arbores cent structures. The depot-warehouse problem described above was addressed by Eppen and Schrage who analyzed a model with a stockless central depot. They derived a closed-form expression for the order-up-to-level under the equal fractile allocation assumption. Several authors have also considered this problem in various forms. Owing to the complexity and intractability of the multi-echelon problem Hadley and Whitin recommend the adoption of single-location, single-echelon models for the inventory systems.Sherbrooke considered an ordering policy of a two-echelon model for warehouse and retailer. It is assumed that stock outs at the retailers are completely backlogged. Also, Sherbrooke constructed the METRIC (multi-echelon technique for coverable item control) model, which identifies the stock levels that minimize the expected number of backorders at the lower-echelon subject to a bud get constraint. This modelis the first multi-echelon inventory model for managing the inventory of service parts. Thereafter, a large set of models which generally seek to identify optimal lot sizes and safety stocks in a multi-echelon framework, were produced by many researchers. In addition to analytical models, simulation models have also been developed to capture the complex interaction of the multi-echelon inventory problems.So far literature has devoted major attention to the forecasting of lumpy demand, and to the development of stock policies for multi-echelon SCs Inventory control policy for multi-echelon system with stochastic demand has been a widely researched area. More recent papers have been covered by Silver and Pyke. The advantage of centralized planning, available in periodic review policies, can be obtained in continuous review policies, by defining the reorder levels of different stages, in terms of echelon stock rather than installation stock.Rau et al. , Diks and de Kok , Dong and Lee ,Mitra and Chatterjee , Hariga , Chen ,Axsater and Zhang , Nozick and Turnquist ,and So and Zheng use a mathematic modeling technique in their studies to manage multi-echelon inventory in SCs. Diks and de Kok’s study considers a divergent multi-echelon inventory system, such as a distribution system or a production system, and assumes that the order arrives after a fixed lead time. Hariga, presents a stochastic model for a single-period production system composed of several assembly/processing and storage facilities in series. Chen, Axsater and Zhang, and Nozick and Turnquist consider a two-stage inventory system in their papers. Axsater and Zhang and Nozickand Turnquist assume that the retailers face stationary and independent Poisson demand. Mitra and Chatterjee examine De Bodt and Graves’ model (1985), which they developed in their paper’ Continuous-review policies for a multi-echelon inventory problem with stochastic demand’, for fast-moving items from the implementation point of view. The proposed modification of the model can be extended to multi-stage serial and two -echelon assembly systems. In Rau et al.’s model, shortage is not allowed, lead time is assumed to be negligible, and demand rate and production rate is deterministic and constant. So and Zheng used an analytical model to analyze two important factors that can contribute to the high degree of order-quantity variability experienced bysemiconductor manufacturers: supplier’s lead time and forecast demand updating. They assume that the external demands faced by there tailor are correlated between two successive time periods and that the retailer uses the latest demand information to update its future demand forecasts. Furthermore, they assume that the supplier’s delivery lead times are variable and are affected by the retailer’s order quantities. Dong and Lee’s paper revisits the serial multi-echelon inventory system of Clark and Scarf and develops three key results. First, they provide a simple lower-bound approximation to the optimal echelon inventory levels and an upper bound to the total system cost for the basic model of Clark and Scarf. Second, they show that the structure of the optimal stocking policy of Clark and Scarf holds under time-correlated demand processing using a Martingale model of forecast evolution. Third, they extend the approximation to the time-correlated demand process and study, in particular for an autoregressive demand model, the impact of lead times, and autocorrelation on the performance of the serial inventory system.After reviewing the literature about multi-echelon inventory management in SCs using mathematic modeling technique, it can be said that, in summary, these papers consider two, three, or N-echelon systems with stochastic or deterministic demand. They assume lead times to be fixed, zero, constant, deterministic, or negligible. They gain exact or approximate solutions.Dekker et al. analyses the effect of the break-quantity rule on the inventory costs. The break-quantity rule is to deliver large orders from the warehouse, and small orders from the nearest retailer, where a so-called break quantity determines whether an order is small or large. In most l-warehouse–N-retailers distribution systems, it is assumed that all customer demand takes place at the retailers. However, it was shown by Dekker et al. that delivering large orders from the warehouse can lead to a considerable reduction in the retailer’s inventory costs. In Dekker et al. the results of Dekker et al. were extended by also including the inventory costs at the warehouse. The study by Mohebbi and Posner’s contains a cost analysis in the context of a continuous-review inventory system with replenishment orders and lost sales. The policy considered in the paper by V ander Heijden et al. is an echelon stock, periodicreview, order-up-to policy, under both stochastic demand and lead times.The main purpose of Iida’s paper is to show that near-myopic policies are acceptable for a multi-echelon inventory problem. It is assumed that lead times at each echelon are constant. Chen and Song’s objective is to minimize the long-run average costs in the system. In the system by Chen et al., each location employs a periodic-review, or lot-size reorder point inventory policy. They show that each location’s inventory positions are stationary and the stationary distribution is uniform and independent of any other. In the study by Minner et al., the impact of manufacturing flexibility on inventory investments in a distribution network consisting of a central depot and a number of local stock points is investigated. Chiang and Monahan present a two-echelon dual-channel inventory model in which stocks are kept in both a manufacturer warehouse (upper echelon) and a retail store (lower echelon), and the product is available in two supply channels: a traditional retail store and an internet-enabled direct channel. Johansen’s system is assumed to be controlled by a base-stock policy. The independent and stochastically dependent lead times are compared.To sum up, these papers consider two- or N-echelon inventory systems, with generally stochastic demand, except for one study that considers Markov-modulated demand. They generally assume constant lead time, but two of them accept it to be stochastic. They gain exact or approximate solutions.In multi-echelon inventory management there are some other research techniques used in literature, such as heuristics, vary-METRIC method, fuzzy sets, model predictive control, scenario analysis, statistical analysis, and GAs. These methods are used rarely and only by a few authors.A multi-product, multi-stage, and multi-period scheduling model is proposed by Chen and Lee to deal with multiple incommensurable goals for a multi-echelon SC network with uncertain market demands and product prices. The uncertain market demands are modeled as a number of discrete scenarios with known probabilities, and the fuzzy sets are used for describing the sellers’ and buyers’ incompatible preference on product prices.In the current paper, a detailed literature review, conducted from an operational research point of view, is presented, addressing multi-echelon inventory management in supply chains from 1996 to 2005.Here, the behavior of the papers, against demand and lead time uncertainty, is emphasized.The summary of literature review is given as: the most used research technique is simulation. Also, analytic, mathematic, and stochastic modeling techniques are commonly used in literature. Recently, heuristics as fuzzy logic and GAs have gradually started to be used.Source: A Taskin Gu¨mu¨s* and A Fuat Gu¨neri Turkey, 2007. “Multi-echelon inventory management in supply chains with uncertain demand and lead times: literature review from an operational research perspective”. IMechE V ol. 221 Part B: J. Engineering Manufacture. June, pp.1553-1570.译文:供应链下的多级存货管理从历史上看,多级供应链、仓库、分销商、零售商等,已经通过大量的库存缓冲被独立管理。

供应商管理库存系统外文文献翻译最新译文文献出处:Kannan G, Grigore M C, Devika K, et al. An analysis of the general benefits of a centralised VMI system based on the EOQ model [J]. International Journal of Production Research, 2013, 51(1): 172-188.An analysis of the general benefits of a centralised VMI systembased on the EOQ modelG. Kannan, M. C. Grigore, K. Devika & A. Senthilkumar1.IntroductionDue to the global expansion of large companies, competition all over the world is becoming stronger and therefore an increasing need to obtain competitive prices is pushing industries to take on new challenging, strategic methods. One of the recently recognised methods is the replacement of the traditional supply chain with the vendor-managed inventory (VMI) supply chain. It has been proven in many different papers that the VMI supply chain is superior to the traditional supply chain and can bring significant cost savings to the participants.A traditional supply chain refers to the system within which each of the members at the different stages make decisions regarding replenishment quantities and timing so as to minimise cost at their end of the supply chain. The supply chain usually consists of all stages, starting at the raw material supplier and continuing on until the finished product reaches the end customer. All the different stages are linked by their common aim of providing the right product to the right customer in the promised time.VMI is a replenishment supply chain technique that has beenimplemented since the beginning of the 1980s by Wall-Mart and Procter & Gamble (Waller et al. 1999), and has its roots back in 1958 when Magee (1958) first introduced the concept.Within a VMI agreement, the upstream supply chain member (the vendor) takes responsibility for managing the inventory of the downstream member (the buyer) within specific levels previously agreed upon without the need for orders from the customer side to be placed. Therefore, the vendor can focus on optimising production efficiency and capacity planning, while the customer has to improve forecastaccuracy.The success of VMI is dependent on communication between the partners, their willingness to share data, collaboration and coordination, and an information technology system which enables fast access to critical information (Duchessi and Chengalur-Smith 2008).The general characteristics of a traditional supply chain and of a VMI supply chain, formed by three stage.The research here is meant to offer a simple overview of the possible outcomes after VMI implementation in a two-stage supply chain, between the vendor and its multiple buyers. The analysis focuses on the overall supply chain cost impact, which VMI can show under specific conditions, based on the practical experience learned in the pharmaceutical industry.Using VMI in a supply chain brings transparency regarding essential information among the partners, thus giving the opportunity at each stage to adjust the decisions in a timely manner and avoid emergency situations.The VMI supply chain implies coordination between the partnering stages, continuous information sharing, and regularmeetings where critical issues are discussed and follow-up actions are noted.The general benefits model analysed in this paper is based on the economic ordering quantity (EOQ) model and is an extension of Bookbinder et al.'s (2010) paper. As an extension of the aforementioned work, the model has been adjusted to integrate different requirements and constraints from within the pharmaceutical industry. It has been further extended from analysing a one-vendor, one-buyer deterministic demand case to analysing a one-vendor, multiple-buyer stochastic demand case.The mathematical model applies to two echelons, the vendor and its multiple buyers. An observation is made here to distinguish that the buyers are not the end-consumers but represent sales organisations from each country. At the same time both the vendor and buyers belong to the same organisation.In the literature, one of the main challenges when implementing VMI has beenidentified in providing the right incentives for all partners to do their best for the supply chain and the right contract to share the overall profits (Nagarajan and Rajagopalan 2008).The fact that both stages belong to the same organisation facilitates simpler developments further. There is no need for complicated contracts for profit sharing between the two partners in a VMI case, as the most important thing is the total supply chain profit. It can be assumed that both partners have the right incentives to increase overall supply chain profits.Based on the assumptions above, the traditional supply chain model is developed according to its general characteristics within which the centralised organisation does not show anyimpact, while the VMI model is developed as and when decisions are taken centrally to obtain overall supply chain cost reductions.2. Literature reviewThe literature review of this paper is divided into two categories: first, an overview of general positive characteristics observed after the VMI implementation (or) assumed to occur behind the theoretical model and then the second part looks at the literature which clearly focused on the EOQ modeling to determine the potential benefits of a VMI supply chain.2.1 General characteristics of VMI outcomesThis section verifies the outcomes of a VMI relationship and presents a short literature review of different benefits which have been recognised by other authors to be the outcome of VMI partnerships. A couple of articles have directly addressed the general benefits which can be achieved from a VMI partnership without necessarily developing a model to prove their arguments but through empirical research.Lee et al. (2008) analysed how lean systems would perform with VMI, Collaborative Planning, Forecasting and Replenishment (CPFR), and continuous replenishment and identified that expenses can be significantly decreased and flexibility improved under VMI. Elvander et al. (2007) developed a framework for a VMI configuration with four categories: inventory-related dimensions, information-related dimensions, decision-making dimensions, and a systemintegration level. Dorling et al. (2006) evaluated VMI under oligopolistic competition and defined five steps towards VMI implementation. Donget al. (2007) surveyed the literature and identified that VMI is adopted when the supplier deals with high market competitiveness and when there is good cooperationbetween the supplier and the buyer.Blatherwick (1998), Disney et al. (2003), and Sari (2008) identified that VMI can be outperformed by other strategies in specific situations.2.2 General benefits models of VMI based on the EOQ modelThe literature review presented below focuses strictly on research papers which have developed specific models to evaluate the benefits of a VMI supply chain based on EOQ modelling.Bookbinder et al. (2010), Yao et al. (2007), and Razmi et al. (2010) evaluated the supply chain costs under a traditional supply chain compared to a VMI situation. All cases considered a two-echelon model formed by a vendor and a buyer, and the model development was based on the EOQ formula.Bookbinder et al. (2010) compared three cases: the traditional supply chain, VMI, and central decision making. The difference between traditional supply chains and VMI was obtained through transferring the cost of placing an order, which was incurred by the buyer, to the vendor under the VMI. Also, the vendor's cost of placing an order has been considered to be lower than the buyer's. One of the findings of the model is that both the vendor and the buyer are better off as long as the vendor's holding costs divided by the buyer's holding cost are higher than the ordering cost.Yao et al. (2007) showed that total costs can be decreased under VMI as long as the ordering cost of the vendor is lower than that of the buyer. However, results also show that the buyer has greater benefits than the vendor.Razmi et al. (2010) effectuated a sensitivity analysis by varying the parameter values of the total cost function whileincluding a backordering cost in the calculation. While in the traditional supply chain model both the vendor and the customer incurred costs, in the case of VMI all the costs have been attributed to the vendor. Pasandideh et al. (2010) used an EOQ model to evaluate the impact of differentparameters on the total cost when applying VMI and when shortage is backlogged. The EOQ model developed showed that VMI could bring important cost savings but this has its limitations on the values of the ordering costs of the two participants.Zhang et al. (2007) analysed the total cost function incurred under a VMI partnership where an exponential function of the ordering costs was taken. The model was applied to a one-vendor, one-buyer case and proved that decreasing the ordering cost represents an investment which brings lower costs for all buyers. Teng et al. (2005) used integer programming to extend the classic economic production quantity (EPQ) model to allow for time varying cost, with deterministic demand. The findings showed that the total cost is a convex function of the number of replenishments, for which the minimum number should be identified for savings to be obtained. Chen and Wei (2011) examined the optimal dynamic joint decisions using a calculus-based formulation combined with dynamic programming techniques in a vertically decentralised single manufacturer Stackelberg and single-retailer channel over a multi-period planning horizon subject to deteriorating goods and multivariate demand function. Niranjan et al. (2011) analysed the issues surrounding the VMI implementation using 15 features categorised as product related, company related, or supplier related. In addition to the researchers mentioned in Table 1, the following researchers have also analysed the benefits of the VMIsystem (Disney and Towill 2002b, Sourirajan et al. 2008, Bakal and Geunes 2009, Battini et al. 2009, Wang 2009, Liu and ?etinkaya 2010, Borade et al. 2011).Zhang et al. (2007) developed an integrated VMI, where a joint cost model was built under the assumption of constant demand rate and production. The model evaluates the impact on the total cost function when varying the ordering cost. Ordering costs can be reduced through a VMI partnership, and the partners can share the benefits. Later, a model to indicate the general benefits which a VMI partnership could bring, and adjusted to the pharmaceutical case, will be developed.Many authors have focused their attention on the analysis of the VMI performance based on constant demand characteristics, for which the EOQ model represents the basis for the analysis. While researching the general benefits of VMIbased on EOQ model literature, one of the gaps identified is the fact that evaluations were done strictly between one vendor and one buyer. The only exception is identified in Zhang et al. (2007), who considered two buyers but focused on order cost reduction evaluation.Based on the findings in the literature, this paper extends previous research and analyses the possible benefits when dealing with one vendor and multiple buyers assuming a stochastic, constant type of demand.3. Problem definition and research scopeThe objective of this paper is to develop a relevant model which integrates specific constraints from the pharmaceutical industry and which has the ability to project the possible cost differences between a traditional supply chain and a VMI supply chain.Some of the aspects which the model will integrate are: constant demand, variable demand, evaluation of a two-stage supply chain composed of a vendor and his multiple buyers, and identification of the importance of fast reaction to demand changes and maintenance of a high customer service level as defined by the industry.The characteristics are integrated in both traditional and VMI supply chains, while the model is based on the EOQ model rational with the purpose of highlighting cost differences between the two. Under the VMI supply chain, the transportation cost and the cost of issuing an order are transferred from the buyer to the vendor.The structure of the paper is as follows: Section 4 develops the mathematical model for the traditional and VMI supply chains, and this is then numerically applied in Section 5. The results of the numerical application are discussed in Section 6, and Section 7 presents an overall conclusion of the paper and identifies directions for further research opportunities.3.1 Research highlightsThe model developed in this paper extends previous works which based their analysis of traditional versus VMI supply chains on EOQ models by acknowledging demand variability and integrating preventive actions.Another difference which is captured within this model represents the extendednumber of buyers evaluated. While previous research focused on one-vendor, one-buyer cases, the model here integrates one vendor and multiple buyers.Evaluating the situation of multiple buyers with whom the vendor has the possibility to establish VMI partnerships givesmore flexibility to the vendor to consolidate specific product demands. Based on this opportunity, the model is structured to evaluate benefits depending on the number of products shared among more buyers.译文基于经济订购量模式的供应商管理库存系统的综合效益分析G. Kannan, M. C. Grigore, K. Devika & A. Senthilkumar1 引言由于大公司的全球化扩张,世界各地的竞争越来越强烈,因此越来越需要获得具有竞争力的价格,这对企业来说是一个全新的挑战,但也是推动产业发展的战略方法。

本科毕业论文(设计)外文翻译原文:Multi-echelon inventory management in supply chains Historically, the echelons of the supply chain, warehouse, distributors, retailers, etc., have been managed independently, buffered by large inventories. Increasing competitive pressures and market globalization are forcing firms to develop supply chains that can quickly respond to customer needs. To remain competitive and decrease inventory, these firms must use multi-echelon inventory management interactively, while reducing operating costs and improving customer service.Supply chain management (SCM) is an integrative approach for planning and control of materials and information flows with suppliers and customers, as well as between different functions within a company. This area has drawn considerable attention in recent years and is seen as a tool that provides competitive power .SCM is a set of approaches to integrate suppliers, manufacturers, warehouses, and stores efficiently, so that merchandise is produced and distributed at right quantities, to the right locations and at the right time, in order to minimize system-wide costs while satisfying service-level requirements .So the supply chain consists of various members or stages. A supply chain is a dynamic, stochastic, and complex system that might involve hundreds of participants.Inventory usually represents from 20 to 60 per cent of the total assets of manufacturing firms. Therefore, inventory management policies prove critical in determining the profit of such firms. Inventory management is, to a greater extent, relevant when a whole supply chain (SC), namely a network of procurement, transformation, and delivering firms, is considered. Inventory management is indeed a major issue in SCM, i.e. an approach that addresses SC issues under an integrated perspective.Inventories exist throughout the SC in various forms for various reasons. Thelack of a coordinated inventory management throughout the SC often causes the bullwhip effect, namely an amplification of demand variability moving towards the upstream stages. This causes excessive inventory investments, lost revenues, misguided capacity plans, ineffective transportation, missed production schedules,and poor customer service.Many scholars have studied these problems, as well as emphasized the need of integration among SC stages, to make the chain effectively and efficiently satisfy customer requests (e.g. reference). Beside the integration issue, uncertainty has to be dealt with in order to define an effective SC inventory policy. In addition to the uncertainty on supply (e.g. lead times) and demand, information delays associated with the manufacturing and distribution processes characterize SCs.Inventory management in multi-echelon SCs is an important issue, because thereare many elements that have to coordinate with each other. They must also arrangetheir inventories to coordinate. There are many factors that complicate successful inventory management, e.g. uncertain demands, lead times, production times, product prices, costs, etc., especially the uncertainty in demand and lead times where the inventory cannot be managed between echelons optimally.Most manufacturing enterprises are organized into networks of manufacturingand distribution sites that procure raw material, process them into finished goods, and distribute the finish goods to customers. The terms ‘multi-echelon’ or ‘multilevel‘production/distribution networks are also synonymous with such networks(or SC), when an item moves through more than one step before reaching the final customer. Inventories exist throughout the SC in various forms for various reasons. Atany manufacturing point, they may exist as raw materials, work in progress, or finished goods. They exist at the distribution warehouses, and they exist in-transit, or‘in the pipeline’, on each path linking these facilities.Manufacturers procure raw material from suppliers and process them into finished goods, sell the finished goods to distributors, and then to retail and/or customers. When an item moves through more than one stage before reaching thefinal customer, it forms a ‘multi-echelon’ inventory system. The echelon stock of a stock point equals all stock at this stock point, plus in-transit to or on-hand at any of its downstream stock points, minus the backorders at its downstream stock points.The analysis of multi-echelon inventory systems that pervades the business world has a long history. Multi-echelon inventory systems are widely employed to distribute products to customers over extensive geographical areas. Given the importance of these systems, many researchers have studied their operating characteristics under a variety of conditions and assumptions. Since the development of the economic order quantity (EOQ) formula by Harris (1913), researchers and practitioners have been actively concerned with the analysis and modeling of inventory systems under different operating parameters and modeling assumptions .Research on multi-echelon inventory models has gained importance over the last decade mainly because integrated control of SCs consisting of several processing and distribution stages has become feasible through modern information technology. Clark and Scarf were the first to study the two-echelon inventory model. They proved the optimality of a base-stock policy for the pure-serial inventory system and developed an efficient decomposing method to compute the optimal base-stock ordering policy. Bessler and Veinott extended the Clark and Scarf model to include general arbores cent structures. The depot-warehouse problem described above was addressed by Eppen and Schrage who analyzed a model with a stockless central depot. They derived a closed-form expression for the order-up-to-level under the equal fractile allocation assumption. Several authors have also considered this problem in various forms. Owing to the complexity and intractability of the multi-echelon problem Hadley and Whitin recommend the adoption of single-location, single-echelon models for the inventory systems.Sherbrooke considered an ordering policy of a two-echelon model for warehouse and retailer. It is assumed that stock outs at the retailers are completely backlogged. Also, Sherbrooke constructed the METRIC (multi-echelon technique for coverable item control) model, which identifies the stock levels that minimize the expected number of backorders at the lower-echelon subject to a bud get constraint. This modelis the first multi-echelon inventory model for managing the inventory of service parts. Thereafter, a large set of models which generally seek to identify optimal lot sizes and safety stocks in a multi-echelon framework, were produced by many researchers. In addition to analytical models, simulation models have also been developed to capture the complex interaction of the multi-echelon inventory problems.So far literature has devoted major attention to the forecasting of lumpy demand, and to the development of stock policies for multi-echelon SCs Inventory control policy for multi-echelon system with stochastic demand has been a widely researched area. More recent papers have been covered by Silver and Pyke. The advantage of centralized planning, available in periodic review policies, can be obtained in continuous review policies, by defining the reorder levels of different stages, in terms of echelon stock rather than installation stock.Rau et al. , Diks and de Kok , Dong and Lee ,Mitra and Chatterjee , Hariga , Chen ,Axsater and Zhang , Nozick and Turnquist ,and So and Zheng use a mathematic modeling technique in their studies to manage multi-echelon inventory in SCs. Diks and de Kok’s study considers a divergent multi-echelon inventory system, such as a distribution system or a production system, and assumes that the order arrives after a fixed lead time. Hariga, presents a stochastic model for a single-period production system composed of several assembly/processing and storage facilities in series. Chen, Axsater and Zhang, and Nozick and Turnquist consider a two-stage inventory system in their papers. Axsater and Zhang and Nozickand Turnquist assume that the retailers face stationary and independent Poisson demand. Mitra and Chatterjee examine De Bodt and Graves’ model (1985), which they developed in their paper’ Continuous-review policies for a multi-echelon inventory problem with stochastic demand’, for fast-moving items from the implementation point of view. The proposed modification of the model can be extended to multi-stage serial and two -echelon assembly systems. In Rau et al.’s model, shortage is not allowed, lead time is assumed to be negligible, and demand rate and production rate is deterministic and constant. So and Zheng used an analytical model to analyze two important factors that can contribute to the high degree of order-quantity variability experienced bysemiconductor manufacturers: supplier’s lead time and forecast demand updating. They assume that the external demands faced by there tailor are correlated between two successive time periods and that the retailer uses the latest demand information to update its future demand forecasts. Furthermore, they assume that the supplier’s delivery lead times are variable and are affected by the retailer’s order quantities. Dong and Lee’s paper revisits the serial multi-echelon inventory system of Clark and Scarf and develops three key results. First, they provide a simple lower-bound approximation to the optimal echelon inventory levels and an upper bound to the total system cost for the basic model of Clark and Scarf. Second, they show that the structure of the optimal stocking policy of Clark and Scarf holds under time-correlated demand processing using a Martingale model of forecast evolution. Third, they extend the approximation to the time-correlated demand process and study, in particular for an autoregressive demand model, the impact of lead times, and autocorrelation on the performance of the serial inventory system.After reviewing the literature about multi-echelon inventory management in SCs using mathematic modeling technique, it can be said that, in summary, these papers consider two, three, or N-echelon systems with stochastic or deterministic demand. They assume lead times to be fixed, zero, constant, deterministic, or negligible. They gain exact or approximate solutions.Dekker et al. analyses the effect of the break-quantity rule on the inventory costs. The break-quantity rule is to deliver large orders from the warehouse, and small orders from the nearest retailer, where a so-called break quantity determines whether an order is small or large. In most l-warehouse–N-retailers distribution systems, it is assumed that all customer demand takes place at the retailers. However, it was shown by Dekker et al. that delivering large orders from the warehouse can lead to a considerable reduction in the retailer’s inventory costs. In Dekker et al. the results of Dekker et al. were extended by also including the inventory costs at the warehouse. The study by Mohebbi and Posner’s contains a cost analysis in the context of a continuous-review inventory system with replenishment orders and lost sales. The policy considered in the paper by V ander Heijden et al. is an echelon stock, periodicreview, order-up-to policy, under both stochastic demand and lead times.The main purpose of Iida’s paper is to show that near-myopic policies are acceptable for a multi-echelon inventory problem. It is assumed that lead times at each echelon are constant. Chen and Song’s objective is to minimize the long-run average costs in the system. In the system by Chen et al., each location employs a periodic-review, or lot-size reorder point inventory policy. They show that each location’s inventory positions are stationary and the stationary distribution is uniform and independent of any other. In the study by Minner et al., the impact of manufacturing flexibility on inventory investments in a distribution network consisting of a central depot and a number of local stock points is investigated. Chiang and Monahan present a two-echelon dual-channel inventory model in which stocks are kept in both a manufacturer warehouse (upper echelon) and a retail store (lower echelon), and the product is available in two supply channels: a traditional retail store and an internet-enabled direct channel. Johansen’s system is assumed to be controlled by a base-stock policy. The independent and stochastically dependent lead times are compared.To sum up, these papers consider two- or N-echelon inventory systems, with generally stochastic demand, except for one study that considers Markov-modulated demand. They generally assume constant lead time, but two of them accept it to be stochastic. They gain exact or approximate solutions.In multi-echelon inventory management there are some other research techniques used in literature, such as heuristics, vary-METRIC method, fuzzy sets, model predictive control, scenario analysis, statistical analysis, and GAs. These methods are used rarely and only by a few authors.A multi-product, multi-stage, and multi-period scheduling model is proposed by Chen and Lee to deal with multiple incommensurable goals for a multi-echelon SC network with uncertain market demands and product prices. The uncertain market demands are modeled as a number of discrete scenarios with known probabilities, and the fuzzy sets are used for describing the sellers’ and buyers’ incompatible preference on product prices.In the current paper, a detailed literature review, conducted from an operational research point of view, is presented, addressing multi-echelon inventory management in supply chains from 1996 to 2005.Here, the behavior of the papers, against demand and lead time uncertainty, is emphasized.The summary of literature review is given as: the most used research technique is simulation. Also, analytic, mathematic, and stochastic modeling techniques are commonly used in literature. Recently, heuristics as fuzzy logic and GAs have gradually started to be used.Source: A Taskin Gu¨mu¨s* and A Fuat Gu¨neri Turkey, 2007. “Multi-echelon inventory management in supply chains with uncertain demand and lead times: literature review from an operational research perspective”. IMechE V ol. 221 Part B: J. Engineering Manufacture. June, pp.1553-1570.译文:供应链下的多级存货管理从历史上看,多级供应链、仓库、分销商、零售商等,已经通过大量的库存缓冲被独立管理。