外文翻译--稻草到能源--它可能是个有价值的尝试

- 格式:doc

- 大小:51.50 KB

- 文档页数:16

两分钟英语故事:稻草、木炭和豌豆A little while later, the straw thought of a good idea. “Since my body is light and long, if I lie down and stretch myself across the stream you guys can cross.” “Will it be alright?” “We will have to see.” On the one hand, pea and charcoal couldn’t help in worrying.不一会儿,稻草想到了一个好主意。

“我的身体又轻又长,要是我躺下来游过小溪,你们也就可以越过小溪了。

”“这样可以吗”“我们试试看啊”其实,豌豆和木炭还是顾虑重重。

The straw laid across the stream. “Hurry! You must cross quickly. If you stay in one place too long, I could catch on fire.” Charcoal quic kly began crossing over the straw.稻草平躺在小溪上。

“快点!你必须快点过小溪。

如果你在我身上待得太久,我可能会着火。

”木炭很快跳到稻草身上。

But, as charcoal was crossing, he looked down. “I’m scared! Oh what should I do?” Charcoal could no longer move. “Hurry up and cross!” Straw said with all his might.但是,当木炭跳上去之后,他向下俯视着。

“我很害怕!哦,我该怎么办?”“木炭不敢再动弹。

“快起来,跳过去啊!”稻草使出浑身的力气喊道。

稻草建筑材料在未来是否成为可能?露易丝·蒂克尔用稻草修房子并没有为《三只小猪》中的第一只带来任何好处,但是,如果巴斯大学的研究成果被建筑行业所接受的话,那么现代草砖将会成为未来的伟大设计。

说到一个草砖房子,你可能会联想到一个摇摇欲坠的窝棚,它漏水,发出吱吱的响声,随时都会垮塌在地,还带着类似农家的气息。

但是当你踏入BaleHaus的时候,一个被修建于巴斯大学校园里,看起来原始的当代房屋,将会令你吃惊地出展现在你面前,并且,你会发现你无法找到任何一缕稻草。

相反,你在一楼的走廊将会看到一个拥有两间卧室和一个浴室的倒置房子,和楼上一个通风的开放式的生活区。

这就像是从斯堪的纳维亚半岛抵达了萨默赛特郡。

这些由石灰做底泥制成的,干燥稻草捆,原来都是被紧紧捆住并放置于一系列预制好的木质矩形框架结构的墙中的,它们像乐高拼装玩具一样被嵌入一个叫做ModCell 的嵌板中。

这些“草屋”存在的问题似乎并不在于它们并不实用,而是人们意识到它们有点非主流,并且并不是特别耐用。

再加上,这样的草屋很难拿去获得抵押贷款。

巴斯大学BRE的建筑材料创新中心的主管Peter Walker 教授指出,稻草的好处在于:“它是便宜、易于广泛应用的良好绝缘体材料,它被用在房屋建筑上已经好几百年。

”作为整个世界的工业副产品——这些秸秆在谷物收获以后被留下——只要它们不分解,就仍然有效地吸收和固定大气中的碳。

对于建筑行业来说,当前所依赖的材料是无论在生产还是运输上都具有极高的能耗和碳消耗的嵌入式混凝土和砖——因此,稻草可以为解决温室气体排放这一问题提供一个友好的解决方案。

无论这个草屋看上去有多时髦,多现代化还是多环保,你仍然想要知道它是否会在雷电交加的暴风雨中被淋得湿透或者是否会因你打翻的蜡烛,而被被嗖嗖的火焰烧的精光。

Walker 教授和他的研究伙伴公布了他们的研究结果,Dr Katharine Beadle 花费了18个月的时间,通过一个详尽的危险因素清单去测试这个BaleHaus被腐蚀、烧毁、吹倒的可能,到目前为止,这个房子看来似乎是可靠的。

稻草定律作文800范文英文回答,The Straw Man fallacy, also known as the Straw Person fallacy, is a rhetorical technique where someone distorts an opponent's argument in order to make it easier to attack. This fallacy is named after the idea of creating a "straw man" – a figure made of straw that is easy to knock down. In other words, instead of addressing the actual argument made by the opponent, the person using the Straw Man fallacy attacks a distorted or exaggerated version of that argument.One common example of the Straw Man fallacy is when someone misrepresents their opponent's position in order to make it seem weaker or more extreme than it actually is. For instance, if someone argues that we should put more funding into education, and their opponent responds by saying, "So you think we should just throw money at every problem and hope it goes away?" – that would be a Straw Man fallacy. The opponent has distorted the original argument about education funding in order to make it easierto attack.Another example of the Straw Man fallacy is when someone oversimplifies their opponent's argument in order to attack it. For instance, if someone argues that we should have stricter gun control laws, and their opponent responds by saying, "So you want to take away everyone's guns and leave them defenseless?" – that would be a Straw Man fallacy. The opponent has oversimplified the original argument about gun control in order to attack it more easily.It's important to recognize and avoid using the Straw Man fallacy in our own arguments, as it can undermine the quality of our reasoning and the strength of our positions. Instead of distorting or oversimplifying our opponent's arguments, we should strive to engage with their actual points and address them directly.中文回答,稻草定律,也称稻草人谬误,是一种修辞技巧,其中某人扭曲对手的论点,以便更容易进行攻击。

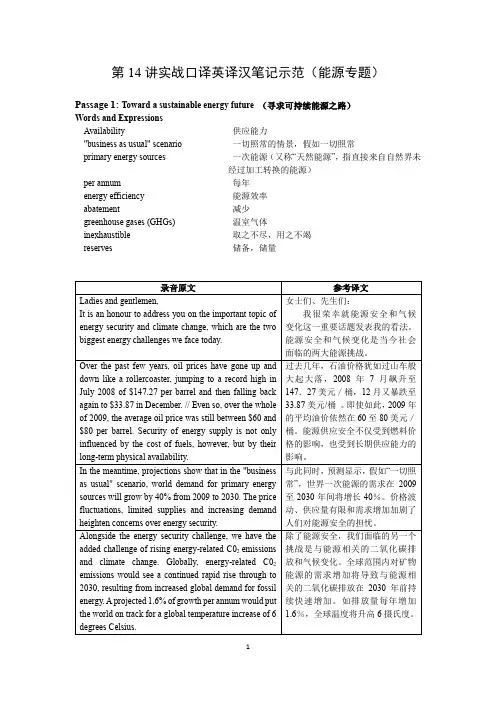

第14讲实战口译英译汉笔记示范(能源专题)Passage 1: Toward a sustainable energy future (寻求可持续能源之路)Words and ExpressionsAvailability供应能力"business as usual" scenario一切照常的情景,假如一切照常primary energy sources一次能源(又称“天然能源”,指直接来自自然界未经过加工转换的能源)per annum每年energy efficiency能源效率abatement减少greenhouse gases (GHGs)温室气体inexhaustible取之不尽,用之不竭reserves储备,储量Passage 2: Energy innovationWords and Expressionsstart-up初创公司energy Information Administration能源信息署department of Energy美国能源部hydrocarbons碳氢化合物spell导致,将为……带来……viable可行的,有效的cost-efficient成本低廉的,具有成本效益的light at the end of the tunnel希望之光,黑暗尽头的光明,曙光unconventional sources非传统能源,非常规能源hydraulic fracturing水力压裂技术horizontal drilling水平钻井技术reverse 扭转frack压裂tight oil致密油tar sands焦油砂temporary reprieve暂时缓解,一时之计reality check审视现状,现状核实frenzy狂热count on指望,依靠silver bullet良方,高招,杀手铜portfolio能源组合,能源结构conserve节约Good morning. It gives me great pleasure to speak at this summit, which gathers 2,500 researchers, entrepreneurs, investors, large companies, start-ups and government officials for three days to discuss energy innovation. //According to projections from the Energy Information Administration of the Department of Energy, the world will see a 47 percent increase in total energy consumption over 2010 levels by 2035, at which point hydrocarbons will make up 79 percent of energy consumption. // This translates to the consumption of 27 percent more oil, 48 percent more gas, and 45 percent more coal in 2035 compared to 2010. Such an outlook spells higher-cost supplies of oil and gas in the future and has intensified the need to find viable, reliable, cost-efficient energy solutions, both for the U.S. and for other countries in the world. //There are many potential solutions on the horizon. But these days many seem to think the light at the end of the energy tunnel is natural gas. The International Energy Agency says global gas production will rise 50 percent by the year 2035; some claim that two-thirds of that growth will come from unconventional sources like shale gas – a market the U.S. completely dominates. // It is claimed that natural gas resources will provide the United States with 100 years of energy thanks to recent technological advancement in hydraulic fracturing and horizontal drilling techniques thatsparked the so-called "shale revolution". Shale gas has grown from about 2 percent of the U.S. natural gas production in 2000 to almost 40 percent now and has reversed the trend of declining gas production numbers. //Will the unconventional sources save our energy future? Geologist David Hughes of the Post Carbon Institute obviously doesn't think so. Hughes finds that unconventional energy is unlikely to accommodate the growing demand if we stick to the current energy consumption pattern, negating the idea that these resources can be counted on as a viable foundation of the energy sector in the long term. // His belief is shared by many other researchers, who strongly believe that the U.S. cannot drill and frack its way to "energy independence". At best, shale gas, tight oil, tar sands, and other unconventional resources only provide a temporary reprieve from having to deal with the real energy problems. //However, this does not mean that natural gas has no role to play in the overall energy mix, but a reality check is needed before the natural gas frenzy spirals out of control. It is simply dangerous to assume that unconventional resources can be counted on heavily in the future, and creating a dependence on natural gas will only serve to prolong the energy issues we currently face. // If unconventional sources are not the only key to our energy independence, what else do we need? My answer to this question is: there is no silver bullet to solve America's or the world's energy problems. There is no magic wand to sweep away all our energy challenges. I've always believed that, in energy, America needs a mixed approach, so diversity is key. // New sources of advanced energy, such as solar and wind, are already part of the portfolio and need continued development. But we must do more. We must create other efficient solutions to generate, store and conserve energy. // Moreover, commitments must be made at the highest level of government to develop policies that will drive cooperation between the public and private sectors. With government, industry and research working together, we have a better chance of advanced energy innovations becoming a reality and creating a more sustainable energy future for generations to come. Thank you. //参考译文:能源创新各位早上好!能在这里发言,我深感荣幸。

发明超级水稻作文英语英文:Super rice is a revolutionary invention that has had a huge impact on agriculture and food production. It is a type of rice that has been genetically modified to be more resistant to pests, diseases, and environmental stress, as well as to have higher yields. This means that farmers can produce more rice with less effort and resources, helping to address food shortages and improve food security.I remember reading about the development of super rice in a scientific journal a few years ago. The researchers had been working on it for a long time, and when they finally succeeded, it was a game-changer for the agricultural industry. I was amazed by the potential of this new type of rice and how it could benefit so many people around the world.One of the key advantages of super rice is its abilityto thrive in challenging environments. For example, in regions with poor soil quality or limited water supply, traditional rice varieties may struggle to grow and produce good yields. However, super rice is engineered to be more resilient and adaptable, allowing it to flourish in these conditions. This is particularly important in developing countries where agriculture is a major source of livelihood for many people.Another benefit of super rice is its resistance to pests and diseases. In the past, farmers often had to use chemical pesticides and herbicides to protect their rice crops, which not only added to their production costs but also had negative environmental impacts. With super rice, the need for these harmful chemicals is significantly reduced, leading to more sustainable and eco-friendly farming practices.In addition to its resilience and productivity, super rice also offers nutritional benefits. It has been enhanced to contain higher levels of essential nutrients such as vitamins and minerals, which can help combat malnutritionand improve public health. This is especially important in regions where rice is a staple food and a major source of nutrition for the population.Overall, super rice has the potential to transform the way we grow and consume rice. It has already made a positive impact in many countries, and I believe its significance will continue to grow in the future. I am excited to see how this innovative technology will contribute to global food security and sustainable agriculture.中文:超级水稻是一项具有革命性意义的发明,对农业和粮食生产产生了巨大影响。

中英文对照外文翻译(文档含英文原文和中文翻译)原文:Biomass co-firing options on the emission reduction and electricity generation costs in coal-fired power plantsAbstractCo-firing offers a near-term solution for reducing CO2 emissions from conventional fossil fuel power plants. Viable alternatives to long-term CO2 reduction technologies such as CO2 sequestration, oxy-firing and carbon loop combustion are being discussed, but all of them remain in the early to mid stages of development. Co-firing, on the other hand, is a well-proven technology and is in regular use though does not eliminate CO2 emissions entirely. An incremental gain in CO2 reduction can be achieved by immediate implementation of biomass co-firing in nearly all coal-fired power plants with minimum modifications and moderate investment, making co-firing a near-term solution for the greenhouse gas emission problem. If a majority of coal-fired boilers operating around the world adopt co-firing systems, the total reduction in CO2 emissions would be substantial. It is the most efficient means of power generation from biomass, and it thus offers CO2 avoidance cost lower than that for CO2 sequestration from existing power plants. The present analysis examinesseveral co-firing options including a novel option external (indirect) firing using combustion or gasification in an existing coal or oil fired plant. Capital and operating costs of such external units are calculated to determine the return on investment. Two of these indirect co-firing options are analyzed along with the option of direct co-firing of biomass in pulverizing mills to compare their operational merits and cost advantages with the gasification option.1. IntroductionThe evidence of the effects of anthropogenic emission on global climate is overwhelming [1]. The threat of increasing global temperatures has subjected the use of fossil fuels to increasing scrutiny in terms of greenhouse gas (GHG) and pollutant emissions. The issue of global warming needs to be addressed on an urgent basis to avoid catastrophic consequences for humanity as a whole.Socolow and Pacala [2] introduced the wedge concept of reducing CO2 emissions through several initiatives involving existing technologies, instead of a single future technology or action that may take longer to develop and stronger willpower to implement. A wedge represents a carbon-cutting strategy that has the potential to grow from zero today to avoiding 1 billion tons of carbon emissions per year by 2055. It has been estimated [3] that at least 15 strategies are currently available that, with scaling up, could represent a wedge of emissions reduction.Although a number of emission reduction options are available to the industry, many of them still face financial penalties for immediate implementation. Some measures are very site/location specific while others are still in an early stage of development. Carbon dioxide sequestration or zero emission power plants represent the future of a CO2 emissions-free power sector, but they will take years to come to the mainstream market. The cost of CO2 capture and sequestration is in the range of 40e60 US$/ton of CO2, depending on the type of plant and where the CO2 is stored [4,5]. This is a significant economic burden on the industry, and could potentially escalate the cost of electricity produced by as much as 60%.Canada has vast amounts of biomass in its millions of hectares of managed forests, most of which remain untapped for energy purposes. Currently, largequantities of the residues from the wood products industry are sent to landfill or are incinerated [6]. In the agricultural sector, grain crops produce an estimated 32 million tons of straw residue per year. Allowing for a straw residue of 85% remaining in the fields to maintain soil fertility, 5 million tons would still be available for energy use. Due to an increase in land productivity, significant areas of land in Canada, which were earlier farmed, are no longer farmed. These lands could be planted withfast-growing energy crops, like switch-grass offering potentially large quantities of biomass for energy production [6].Living biomass plants absorb CO2 from the atmosphere. So, its combustion/gasification for energy production is considered carbon neutral. Thus if a certain amount of biomass is fired in an existing fossil (coal, coke or oil) fuel fired plant generating some energy, the plant could reduce firing the corresponding amount of fossil fuel in it. Thus, a power plant with integrated biomass co-firing has a lower net CO2 contribution over conventional coal-fired plants.Biomass co-firing is one technology that can be implemented immediately in nearly all coal-fired power plants in a relatively short period of time and without the need for huge investments. It has thus evolved to be a near-term alternative to reducing the environmental impact of electricity generation from coal. Biomass co-firing offers the least cost among the several technologies/ options available for greenhouse gas reduction [7]. Principally, co-firing operations are not implemented to save energy but to reduce cost, and greenhouse gas emissions (in some cases). In a typical co-firing plant, the boiler energy usage will be the same as it is operated at the same steam load conditions (for heating or power generation), with the same heat input as that in the existing coal-fired plant. The primary savings from co-firing result from reduced fuel costs when the cost of biomass fuel is lower than that of fossil fuel, and avoiding landfill tipping fees or other costs that would otherwise be required to dispose of unwanted biomass. Biomass fuel at prices 20% or more below the coal prices would usually provide the cost savings needed [8].2. Co-firing optionsBiomass co-firing has been successfully demonstrated in over 150 installationsworldwide for a combination of fuels and boiler types [9]. The co-firing technologies employed in these units may be broadly classified under three types:i. Direct co-firing,ii. indirect co-firing, andiii. gasification co-firing.In all three options, the use of biomass displaces an equivalent amount of coal (on an energy basis), and hence results in the direct reduction of CO2 and NOx emissions to the atmosphere. The selection of the appropriate co-firing option depends on a number of fuel and site specific factors. The objective of this analysis is to determine and compare the economics of the different co-firing options. Brief descriptions of the three co-firing options are presented here.2.1. Direct co-firingDirect co-firing involves feeding biomass into coal going into the mills, that pulverize the biomass along with coal in the same mill. Sometime separate mills may be used or biomass is injected directly into the boiler furnace through the coal burners, or in a separate system. The level of integration into the existing plant depends principally on the biomass fuel characteristics.Four different options are available to incorporate biomass cofiring in pulverized coal power plants [10]. In the first option, the pre-processed biomass is mixed with coal upstream of the existing coal feeders. The fuel mixture is fed into the existing coal mills that pulverize coal and biomass together, and distribute it across the existing coal burners, based on the required co-firing rate. This is the simplest option, involving the lowest least capital costs, but has a highest risk of interference with the coal firing capability of the boiler unit. Alkali or other agglomeration/corrosion-causing agents in the biomass can build-up on heating surfaces of the boiler reducing output and operational time [11]. Furthermore, different combustion characteristics of coal and biomass may affect the stability and heat transfer characteristics of the flame [12]. Thus, this direct co-firing option is applicable to a limited range of biomass types and at very low biomass-to-coal co-firing ratios.The second option involves separate handling, metering, and pulverization of the biomass, but injection of the pulverized biomass into the existing pulverized fuel pipe-work upstream of the burners or at the burners. This option requires only modifications external to the boiler. One disadvantage would be the requirement of additional equipment around the boiler, which may already be congested. It may also be difficult to control and to maintain the burner operating characteristics over the normal boiler load curve.The third option involves the separate handling and pulverizationof the biomass fuel with combustion through a number of burners located in the lower furnace, dedicated to the burning of the biomass alone. This demands a highest capital cost, but involves the least risk to normal boiler operation as the burners are specifically designed for biomass burning and would not interfere with the coal burners.The final option involves the use of biomass as a reburn fuel for NOx emission control. This option involves separate biomass handling and pulverization, with installation of separate biomass fired burners at the exit of the furnace. As with the previous option, the capital cost is high, but risk to boiler operation is minimal.2.2. Indirect or external co-firingIndirect co-firing involves the installation of a completely separate biomass boiler to produce low-grade steam for utilization in the coal-fired power plant prior to being upgraded, resulting in higher conversion efficiencies. An example of this option is the Avedore Unit 2 project in Copenhagen, Denmark. In Canada, Greenfield Research Inc. has developed a similar CFB boiler design that utilizes a number of units of the existing power plant systems like ID fan etc. to reduce the capital cost. In this system, a subcompact circulating fluidized bed boiler is designed specifically to have a piggy-back ride on an existing power plant boiler. Since it is not a stand-alone boiler it does not need many of the equipment or component of a separate boiler. This unit releases flue gas at relatively high temperature and joins the existing flow stream of the parent coal-fired boiler after air heater. Thus, the flue gas from the co-firing unit does not come in contact with any heating elements of the existing boiler, thusavoiding the biomass related fouling or corrosion problem, which is the largest concern of biomass cofiring.This boiler is totally independent of the parent unit, and as such, any outage in the co-firing unit does not affect the generation of the parent plant. Thus this indirect combustion-based option offers high reliability. The piggy-back boiler produces low pressure steam feeding into the process steam header of the power plant. Fig. 1 shows the photograph of one such unit built by Greenfield Research Inc., for a 220MWe Pulverized coal-fired boiler in India. In this specific case, the piggy-back boiler fired waste fuel from the parent boiler as that was the need of the plant.2.3. Gasification co-firingCo-firing through gasification involves the gasification of solid biomass and combustion of the product fuel gas in the furnace of the coal-fired boiler. This approach offers a high degree of fuel flexibility. Since the gas can be injected directly into the furnace for burning, the plant can avoid expensive flue gas cleaning as one would need for syngas or fuel gas for diesel engines. As the enthalpy of the product gas is retained, this results in a very high energy conversion efficiency. If the biomass contains highly corrosive elements like chlorine, alkali etc., a certain amount of gas cleaning may be needed prior to its combustion in the furnace.Another important benefit of injection of gas in the furnace is that it serves as a gas-over firing designed to minimize NOx.Although less popular, indirect or external and gasification cofiring options have certain advantages, such as the possibility to use a wide range of fuels and easy removal of ash. Despite the significantly higher capital investment requirement, these advantages make these two options more attractive to utility companies in some cases.3. Current status of biomass co-firingThere are a number of co-firing installations worldwide, with approximately a hundred in Europe, 40 in the US and the remainder in Australia and Asia (Fig. 2) [9,13]. Most of these installations employ direct co-firing, mainly because it is the simplest and least cost option. Examples include the 635 MWe EPON Project of Gelderland Power Station in Holland which uses direct co-firing with waste wood andthe 150 MWe Studstrup Power Plant, Unit 1, near Aarhus, Denmark co-firing straw.Gasification co-firing is also an attractive option. Three examples of the plants operating on this type of co-firing are: the 137 MWe Zeltweg Power Plant in Styria in Austria, the AMERGAS biomass gasification project at the Amer Power Plant in Geertruidenberg, Holland, and the Kymiarvi power station at Lathi in Finland.The majority of biomass co-firing installations is operated at biomass: coal co-firing ratios of less than 10%, on a heat input basis. The successful operation of these plants shows that co-firing at low ratios does not pose any threat or major problems to the boiler operation.4.ConclusionCo-firing reduces the cost of CO2 reduction as its cost is potentially lower than that for CO2 sequestration in an existing power plant. For example, the cost of sequestration of 40e60$/ton of CO2 was much higher than the 33$/ton CO2 reduction cost through cofiring. The present analysis examines a special external co-firing option in an existing plant with two other co-firing options: direct combustion co-firing, and gasification based indirect co-firing. An analysis carried out for a plant in the eastern Canada indicates that direct co-firing can offer an IRR of more than twice that of indirect co-firing. Direct co-firing however suffers from a major uncertainty about fouling and corrosion of its superheater tubes, and breakdown of the mills while handling biomass. This loss, conservatively estimated at 1%, could have significant impact on the viability of the co-firing option. The novel external co-firing option, needs higher capital investment, but is entirely free from these uncertainties. For high alkali, high chlorine biomass with high moisture content, the loss in capacity factor could increase significantly. A sensitivity analysis of the effect of plant capacity factor on the IRR indicates a strong dependency of IRR on the Capacity Factor (CF). IRR reduces at an increasing rate for a steady loss of CF. However, the plant can operate viably even at a CF loss of 4%, offering an IRR of 22.2%.译文:生物质混燃的燃煤电厂减排和发电成本的选择混烧提供了减少传统化石燃料电厂的二氧化碳排放量近期解决方案。

稻草建筑材料在未来是否成为可能?露易丝·蒂克尔用稻草修房子并没有为《三只小猪》中的第一只带来任何好处,但是,如果巴斯大学的研究成果被建筑行业所接受的话,那么现代草砖将会成为未来的伟大设计。

说到一个草砖房子,你可能会联想到一个摇摇欲坠的窝棚,它漏水,发出吱吱的响声,随时都会垮塌在地,还带着类似农家的气息。

但是当你踏入BaleHaus的时候,一个被修建于巴斯大学校园里,看起来原始的当代房屋,将会令你吃惊地出展现在你面前,并且,你会发现你无法找到任何一缕稻草。

相反,你在一楼的走廊将会看到一个拥有两间卧室和一个浴室的倒置房子,和楼上一个通风的开放式的生活区。

这就像是从斯堪的纳维亚半岛抵达了萨默赛特郡。

这些由石灰做底泥制成的,干燥稻草捆,原来都是被紧紧捆住并放置于一系列预制好的木质矩形框架结构的墙中的,它们像乐高拼装玩具一样被嵌入一个叫做ModCell 的嵌板中。

这些“草屋”存在的问题似乎并不在于它们并不实用,而是人们意识到它们有点非主流,并且并不是特别耐用。

再加上,这样的草屋很难拿去获得抵押贷款。

巴斯大学BRE的建筑材料创新中心的主管Peter Walker 教授指出,稻草的好处在于:“它是便宜、易于广泛应用的良好绝缘体材料,它被用在房屋建筑上已经好几百年。

”作为整个世界的工业副产品——这些秸秆在谷物收获以后被留下——只要它们不分解,就仍然有效地吸收和固定大气中的碳。

对于建筑行业来说,当前所依赖的材料是无论在生产还是运输上都具有极高的能耗和碳消耗的嵌入式混凝土和砖——因此,稻草可以为解决温室气体排放这一问题提供一个友好的解决方案。

无论这个草屋看上去有多时髦,多现代化还是多环保,你仍然想要知道它是否会在雷电交加的暴风雨中被淋得湿透或者是否会因你打翻的蜡烛,而被被嗖嗖的火焰烧的精光。

Walker 教授和他的研究伙伴公布了他们的研究结果,Dr Katharine Beadle 花费了18个月的时间,通过一个详尽的危险因素清单去测试这个BaleHaus被腐蚀、烧毁、吹倒的可能,到目前为止,这个房子看来似乎是可靠的。

2008年12月一、Sustainable development is applied to just about everything from energy to clean water and economic growth, and as a result it has become difficult to question either the basic assumptions behind it or the way the concept is put to use.可持续发展适用于诸如能源,净水,经济增长等几乎所有的方面,因此,要对可持续发展的基本假设或其概念的实施方法提出质疑也变得日益困难。

This is especially true in agriculture, where sustainable development is often taken as the sole measure of progress without a proper appreciation of historical and cultural perspectives.这在农业方面尤其显著,可持续发展经常被认为是农业进步的唯一标准,而这并没有从历史和文化的角度进行适当的评估。

To start with, it is important to remember that the nature of agriculture has changed markedly throughout history, and will continue to do so .medieval agriculture in northern Europe fed, clothed and sheltered a predominantly rural society with a much lower population density than it is today.首先,重要的是认识到农业的本质随着历史的发展已经发生了显著的变化,并且这种变化仍将持续。

TPO65阅读-3 Pastoralism and Agriculture in Iran原文+译文+题目+答案+背景知识原文Pastoralism and Agriculture in Iran①Geographical constraints have had important consequences for the economy and society of Iran. Where rainfall is adequate, there are fertile valleys and grasslands suitable for grazing animals. However, since the natural vegetation tends to be sparse, it is difficult for such animals to remain in one place for any length of time. Thus nomadic pastoralism—keeping livestock (such as sheep and goats) by wandering from place to place—was one of the first and most persistent human economic activities to flourish in this area. This nomadic movement was often of the vertical variety, with people and animals moving from lowlands in wintertime to highlands in summer. The animals raised by the pastoralists provided not only food but also material for crafts such as the making of carpets, thick felt cloth, and tents. The pastoralists were typically organized into large tribal confederations capable of controlling the vast territories needed for maintaining their herds.②The tribes were a powerful social and political factor throughout Iranian history. The skills necessary for herding animals, hunting and chasing off predators, directing migrations, disciplining tribesmen, and protecting lands and animals from rivals could be easily adapted and directed toward military purposes as well. It was typically the tribes that produced the soldiers and rulers of the country and provided the power base for most of its dynasties. Once established, governments needed to cultivate the support of friendly tribal groups and tried to control hostile tribes by combat, deportation, or forcible settlement. At the beginning of the twentieth century, approximately one-fourth of the population were tribal peoples, and they were a potent force in Iranian affairs. With the advent of mechanized armies in the 1930s, however, there were systematic efforts to break the power of the tribes and to coerce the tribal population into a sedentary way of life. These efforts have been largely successful, and the tribes are no longer so significant a force in either the Iranian economy or society. Less than 5 percent of the population now consists of nomadic pastoralists.③The aridity of the Iranian plateau retarded its agricultural development in comparison to adjacent regions such as Mesopotamia, which had great rivers to draw upon for a supply of water. Eventually, at some uncertain date probably about 26 centuries ago, there was a technological breakthrough that made it possible to farm crops outside the few oases, streams, and other places with sufficient rainfall for agriculture. This was the development of underground canals known as qanats. The qanat system took advantage of the natural slope (inclination) of the plateau basins. A well would be dug in the foothills to reach a water source, usually water from melting snow that had seeped underground. Then a sequence of wells and shafts connected by underground canals would be constructed to transport the water to an area suitable for cultivation, where it could support the needs of one or more villages. The slope of the underground canals had to be controlled carefully to prevent erosion, and the interior surface of wells and shafts needed to be kept under constant maintenance to prevent them from collapsing.④Since the canals were underground, loss from evaporation was minimized. Gravity provided the means of moving the water, so no mechanical energy was required to operate the system. The numerous wells and shafts kept the length of the tricky underground canal short and facilitated repairs of each segment. Built up over the centuries, the system eventually became immense. It has been estimated that the total length of the qanat system today, counting wells, shafts, and canals, is in excess of 300,000 kilometers (almost the distance from Earth to the Moon!), which gives some idea of the tremendous investment in money and labor power it represents. Yet the type of agriculture that developed around the qanat system gave modest yields and required hard work from the peasant farmers, who received only a small share of the agricultural produce.译文伊朗的畜牧和农业①地理上的限制对伊朗的经济和社会产生了重要的影响。

稻草定律作文800范文英文回答:The Straw Man Fallacy is a common logical fallacy that occurs when someone misrepresents or distorts an opponent's argument in order to make it easier to attack or refute. This fallacy is named after the practice of creating a straw man, or a scarecrow made of straw, to represent an opponent in a debate. Just as a straw man is easier to knock down than a real person, a distorted or exaggerated version of an argument is easier to refute than theoriginal argument itself.For example, let's say that Person A argues that we should invest more in renewable energy sources such as solar and wind power. Person B, who disagrees with this argument, creates a straw man by misrepresenting Person A's position and claiming that Person A wants to completely eliminate all forms of traditional energy sources, such as oil and gas. Person B then proceeds to attack thisexaggerated version of Person A's argument, claiming that it is unrealistic and would lead to economic disaster.In this example, Person B has committed the Straw Man Fallacy by distorting Person A's argument and attacking a version of it that Person A did not actually make. By misrepresenting Person A's position, Person B avoids addressing the actual arguments and evidence that Person A presented in favor of renewable energy.中文回答:稻草定律是一种常见的逻辑谬误,当某人为了更容易攻击或反驳而曲解或扭曲对手的论点时,就会发生这种谬误。

杂交水稻英文作文英文翻译英文,。

Hybrid rice, also known as hybridized rice, is a type of rice that is produced by crossbreeding two different types of rice plants. This process is done to create aplant that has the desirable traits of both parent plants, such as increased yield, disease resistance, and tolerance to environmental stressors.Hybrid rice was first developed in China in the 1970s and has since spread to other countries. It has become a popular choice for rice farmers because of its higher yield and better quality compared to traditional rice varieties.One of the benefits of hybrid rice is its ability to resist pests and diseases. For example, the IR64 hybridrice variety is resistant to bacterial blight, a disease that can cause significant yield losses in traditional rice varieties. By using hybrid rice, farmers can reduce theirreliance on pesticides and herbicides, which can be harmful to the environment.Another advantage of hybrid rice is its ability toadapt to different growing conditions. For instance, the Swarna-Sub1 hybrid rice variety is tolerant to flooding, which is a common problem in many rice-growing regions.This variety can survive for up to two weeks under water, which is much longer than traditional rice varieties.In addition to its practical benefits, hybrid rice has also had a significant impact on global food security. By increasing rice yields, hybrid rice has helped to feed millions of people around the world. It has alsocontributed to the reduction of poverty in many rural areas, as farmers are able to earn more income from their crops.Overall, hybrid rice has proven to be a valuable innovation in the agricultural industry. Its ability to increase yields, resist pests and diseases, and adapt to different growing conditions has made it a popular choicefor farmers around the world.中文:杂交水稻,也称为杂交化水稻,是通过交叉两种不同的水稻植物而产生的一种水稻。

稻田英文作文文案励志英文回答:The rice paddies, a testament to the resilience and ingenuity of farmers, are a symbol of hope and prosperity in many parts of the world. The emerald green fields, shimmering under the golden rays of the sun, evoke a sense of tranquility and abundance. Yet, behind this idyllic facade lies a tale of hard work, dedication, and an unwavering commitment to nature.In the heart of Asia, where rice cultivation has flourished for centuries, the paddies are more than mere agricultural fields; they are an integral part of the cultural fabric. Farmers, armed with their traditional knowledge and time-honored practices, tend to the paddies with meticulous care, nurturing the delicate seedlings and ensuring their growth. The rhythmic movements of their hands, as they transplant the young plants, create a symphony of human harmony with the natural world.The paddies are a microcosm of the intricate relationship between humans and the environment. The farmers, with their deep understanding of the land, cultivate the rice in a sustainable manner, respecting the delicate balance of the ecosystem. They employ age-old techniques, such as crop rotation and water conservation, to ensure the long-term health of the paddies and the surrounding environment.The rice paddies are not just a source of sustenance; they are also a source of inspiration. Their beauty and resilience serve as a reminder of the human spirit'sability to overcome adversity and thrive. They teach us the importance of patience, perseverance, and a deep connection to the natural world.As we navigate the complexities of modern life, therice paddies offer a timeless lesson in sustainable living. They remind us that true prosperity lies not in endless consumption but in harmony with nature and a profound respect for the interconnectedness of all life.中文回答:稻田,是农民的坚韧和智慧的证明,是世界许多地方希望和繁荣的象征。

朋友圈流传着一个稻草定律作文英文回答:The Straw Law states that when a complex or challenging task is given to a group, each individual tends to contribute less than they would if they were working on the task independently. This phenomenon is often attributed to social loafing, a tendency for individuals to exert less effort when they are part of a group than when they are working alone.There are several factors that can contribute to the Straw Law. One is the diffusion of responsibility. When a task is assigned to a group, each individual may feel less accountable for the outcome, leading to a decrease in individual effort. Additionally, group members may experience social pressure to conform to the group's norms, which may include lower levels of effort.The Straw Law can have negative consequences for groupproductivity and performance. When individuals do not contribute their fair share, the overall quality of the output may suffer. This can lead to missed deadlines, subpar results, and a decrease in motivation among group members.To overcome the Straw Law, groups can implement strategies to increase individual accountability. This may involve setting clear goals and expectations, providing regular feedback, and rewarding individual contributions. Additionally, groups can foster a sense of ownership and responsibility among members by encouraging them to participate in the decision-making process and to take ownership of their tasks.中文回答:稻草定律认为,当一项复杂或具有挑战性的任务交给一个群体时,每个个体所做的贡献往往会少于他们单独完成任务时所做的贡献。

稻草价值与人生价值作文英文回答:The value of straw and the value of life are two completely different concepts. Straw is a material that is commonly used for various purposes, such as animal bedding, thatching roofs, or making crafts. It is an inexpensive and easily accessible resource that serves practical purposes in our daily lives. On the other hand, the value of life is immeasurable and cannot be compared to something as simple as straw.Life is a precious gift that should be cherished and valued. It encompasses a wide range of experiences, emotions, relationships, and opportunities. Each individual has their own unique journey and purpose in life. We have the ability to love, learn, grow, and make a positive impact on the world around us. Life is filled with joy, challenges, and meaningful moments that shape who we are as individuals.For example, imagine a farmer who works hard to grow crops and harvest straw. The value of the straw lies in its usefulness as a resource for the farmer. It can be used to feed animals, provide shelter, or even sold for profit. However, the farmer's life and the experiences he goes through are far more valuable than the straw itself. His dedication, perseverance, and the relationships he forms with his family and community are what truly give meaning and value to his life.Similarly, we can look at the value of life from a different perspective. Let's consider a person who is going through a difficult time and feels like their life has no value. They may be facing challenges, experiencing loss, or struggling with their mental health. In this situation, it is important to recognize that their life still holds immense value, despite the hardships they may be facing. They have the potential to overcome their struggles, find happiness, and make a difference in their own life and the lives of others.中文回答:稻草的价值和人生的价值是两个完全不同的概念。

The Power of RiceIn the vast agricultural landscape of Asia, rice stands as a symbol of resilience and fertility, embodying thespirit of hard work and perseverance. It is not just a staple food crop, but a cultural icon that has nourished generations and sustained communities for millennia. The power of rice lies not only in its nutritional value but also in its ability to unite people, preserve traditions, and drive economic growth.The cultivation of rice is an intricate process that requires meticulous care and attention to detail. From seed selection to soil preparation, from planting to irrigation, and finally to harvesting, each step is crucial for ensuring a bountiful crop. This labor-intensive process reflects the dedication and resilience of farmers who, despite facing challenges such as unpredictable weather patterns and pests, persevere to provide food for their families and communities.The importance of rice extends beyond its nutritional benefits. In many Asian cultures, rice is a central component of dietary habits and social gatherings. It isoften the foundation of meals, accompanying a variety of dishes and flavors. Rice festivals and ceremonies celebrate the harvest, bringing people together to share in the joy of a successful crop. These traditions not only strengthen community bonds but also preserve cultural heritage and values.Moreover, the power of rice is also evident in its economic impact. Rice production is a significant contributor to the agricultural economies of many Asian countries. It generates employment opportunities for millions of farmers and their families, providing a stable source of income and livelihood. The rice industry also supports a vast network of suppliers, distributors, and processors, driving economic growth and development.In recent years, the rice industry has also been at the forefront of innovation and sustainability efforts. Farmers are adopting modern farming techniques and technologies to improve yields and reduce environmental impacts. Research and development efforts are focused on enhancing the nutritional value and resilience of rice varieties, addressing challenges such as climate change and pests.The power of rice is not just about its physical presence in our lives but also about the intangible valuesit represents. It is a symbol of unity, fertility, and prosperity. It reminds us of the importance of hard work, perseverance, and community in shaping our lives and futures. As we look ahead to the future of agriculture and food security, the power of rice will continue to be a guiding force, inspiring us to innovate, collaborate, and preserve our cultural heritage.**水稻的力量**在亚洲广阔的农业景观中,水稻是坚韧和富饶的象征,体现了勤劳和毅力的精神。

人们怎么处理秸秆英文作文英文:As we all know, straw is an agricultural byproduct that is left over after the harvest of crops such as wheat, rice, and corn. In many parts of the world, farmers burn thestraw after harvest as a means of disposal. However, this practice is not only harmful to the environment but also contributes to air pollution. Therefore, it is important to find alternative ways to deal with straw.There are several ways to handle straw. One common method is to use it as animal feed. Straw can be used as a source of roughage for livestock, such as cows and horses. Another method is to use it as a source of energy. Strawcan be burned to produce heat and electricity. This is a sustainable method as it reduces the use of non-renewable energy sources.In addition, straw can also be used as a raw materialfor various products. For example, straw can be used to make paper, cardboard, and even furniture. This not only reduces waste but also creates new economic opportunities.中文:众所周知,秸秆是农业生产中的副产品,如小麦、稻谷和玉米收获后剩余的部分。

---------------------------------------------------------------最新资料推荐------------------------------------------------------ 外文翻译--稻草到能源--它可能是个有价值的尝试一项华盛顿州立大学的研究已经发现华盛顿东部的小麦、大麦和草生产的播种栽培者依靠农作物残渣每年可以激发电力的大约400-425个百万瓦电力; 比Snake River上的任何一个大坝的能量都要多。

但是来自稻草生产的能源比水电和核子更贵,不过综合考虑所制定的价格、环境的利益和不稳定的电力市场,显然稻草能源更具有吸引力。

长久以来,世界各个区域的研究人员都在寻找一种能替代野外燃烧稻草的处理方法来减少污染。

尽管有许多种可供选择的使用方法,但是能源部门对于潜在的能够消耗大量的稻草这个市场表现的非常可观。

在一些区域,比如说加利福尼亚州,现存的产生能源的设备是随着稻子的生产而产生的,使他们吸引人利用稻草。

不幸的是,当谷粒收获时的稻草如果在传统的发电厂点燃将会产生一种含有矽石和钾的的渣,稻草中的氯进入火炉和煮器也会加速腐蚀。

钾和氯会迅速的和来自包括稻草在内的生物中的水一起被过滤。

当稻草被暴露在雨水中时,这种过滤自然就发生了。

过滤也能通过各种机械的处理方法产生。

1 / 16无论如何,对于能够得出在燃烧中能导致的较高的灰熔性温度和较低的碱和卤素的挥发,这一结果本身就是一个显著的进步。

通过过滤燃烧稻草这种进步已经成功的在实验室里得到证明。

华盛顿东部的栽培者生产小麦、大麦和草种子等丰富农作物。

依照这样下来,他们生产了数以百万计的大量的稻草。

多余的农作物残渣能导致农作物产量减少,繁殖更多对农作物有害之物, 而且为种植下一轮农作物形成一个障碍。

多余的农作物残渣的处理, 尤其在田地最多的乡村中,确实是一个问题。

秸秆焚烧, 过去大多数的解决方法, 不再被社会所接受。

西北能源计划委员会的报告表明,在过去的十年内, 能量的需求在华盛顿、奥勒冈州和爱达荷州已经增加了 24% 但是当地的能量的产量增加只有区区4 %。

当要求已经超过补给的时候用于购买能源的费用已经急速增长。

结果,地方税纳税人已经在用电的帐单中看到了费用的增加。

加利福尼亚州的能源危机已经导致了西北地区的能源供给短缺。

依靠着有利的天气情况,华盛顿和奥勒冈州从加利福尼亚进口和出口能源。

2019年的暖湿气流留下的低强度的雪层补给了水源增加了水电站的发电能力。

---------------------------------------------------------------最新资料推荐------------------------------------------------------ 利用秸秆的燃烧而从中获取能量也并不是什么新技术。

在美国还没有一套秸秆燃烧设备的时候,一些欧洲的国家, 包括丹麦、英国和西班牙, 已经开始使用那些又大又有效果的植物, 每年燃烧二百万吨的稻草用来获取能量。

在1998年春天,从圣克里门托山谷的两个商业区收集的100公吨干稻草,在雨中暴露7 个月之后,这堆稻谷高度缩减717毫米。

67公吨稻草被压缩后放到粮仓里。

取一半这种材料与基线木材燃料混合,在一个司炉中燃烧。

另一半与农业/都市的木材混合并在一张液体循环床中燃烧。

剩余的33公吨被压缩后和稻谷壳混合后在一个中间点燃的煮器中燃烧。

便于比较,测试也在使用的每个设备中放有不含稻草的混合基线燃料。

因为中止点燃的煮器存在问题,一些实验在这个设备中实行。

在另外两个设备中,混合稻草的单一实验没有出现问题。

在测试期间, 燃料的样品,底部灰和飞行灰是在固定的间隔收集。

司炉炉篦煮器是提供蒸气的三个的煮器之一通常产生器总计供应为50 MWe 的用网络输出。

CFB 煮器用这 25 MWe 网输出是一单位。

3 / 16中止点燃的煮器也是一选出单位用这 26. 5 MWe 网输出。

测试在定格的负荷下被实行除了中止点燃单位的情况。

在那情况, 那的问题就在上次稻草测试避免在 20 MWe 上操作。

所有的测试, 包括基线, 在 20 MWe被修理了之后被固定。

因此火炉出口瓦斯温度 (FEGT) 比在最高负荷还要低。

在测试期间没有发生煤烟吹制。

车床探测器显示当燃烧稻草时沉淀物的特定比率会减少。

这个比率表明在以铁为基础上除去因腐蚀率和不同量的探针导致的不一致的效果。

虽然可获得的稻草数量是有限, 而且测试的期间很短 (5-7 h) 、观察的过热器和没有改变的沉淀物是一致的。

稻草/木材混和沈淀率方面的减少为是可观的, 而且伴随着沉淀物中碱的减少。

一项华盛顿州大学研究正在尝试确定可以利用的稻草量是多少, 并计算出了从田地里面焚烧秸秆所能消耗的所有费用; 建立和操作这种燃烧这种电站的费用, 和制定由此生产的电力的收支平衡的价格。

研究发现那些华盛顿谷粒栽培者每年能生产大约三百万吨经济上可以利用的稻草。

这些稻草具有每年能生产大约有 400-425个百万瓦的能量的潜能。

---------------------------------------------------------------最新资料推荐------------------------------------------------------所需要的电的费用大约每 kwh 大约 8. 5 分。

综合考虑制定的价格、环境的利益和不稳定的能源市场各方面因素,稻草到能源的想法依然值得商榷,因为这个价格仍然比水电和核能发电要高很多。

电力生产者需要考虑价格因素来给他们的产品定价。

虽然从稻草中获得的能量在经济上处于边缘劣势, 但是必须同时考虑到它的来源的费用是相当低的, 可能使它在经济上能实行,尤其是在低成本的能源被限制和处于短缺之中时。

能源市场的近期不稳定可能提供另外的激励。

研究人员最后得出结论,要开始这种从稻草到能源的转变需要适当的商业组织提供合作。

这样的话,那些种植稻子的人不仅仅受益于处理这种副产品所带来的收益,还会受益于出售稻草以及管理/所有权分离的农场企业的收益Straw-to-Energy? It Might Be Worth A Try A Washington State University study has found that crop residueproduced by Eastern Washington wheat, barley, and grass seedgrowers could fuel the generation of about 400-425 megawattsof electricity annually; more than that produced by any one ofour current Snake River dams. While energy production fromstraw is more expensive than hydro and nuclear, blend pricing, environmental benefits, and the volatile electricity market5 / 16make it attractive. In many areas of the world to reduce air pollution. Although there are many alternative uses, the energy sector represents a substantial market with the potential of consuming large quantities of straw. In some areas, such as in California, existing power generation facilities are with rice production, making them attractive utilization sites for straw. Alternatives to the open burning disposal of rice straw have long been sought Unfortunately, rice straw, as it is available immediately following grain harvest, contains a combination of silica and potassium that leads to heavy slogging and fouling if fired in conventional combustion power plants. Chlorine in straw also accelerates corrosion in furnaces and boilers. Potassium and chlorine are readily leached with water from biomass including straw .Such leaching occurs naturally when straw is exposed to rain. Leaching can also be effected through various mechanical treatments. In either case, the result is a remarkable improvement in combustion behavior leading to substantially higher ash fusibility temperatures and lower alkali and halogen volatilization. Improvements to the combustion properties of rice straw via leaching have been well demonstrated in the laboratory. Eastern Washington growers produce---------------------------------------------------------------最新资料推荐------------------------------------------------------abundant crops of wheat, barley, and grass seed. In doing so,they produce millions of tons of straw. Excess crop residuecan serve to reduce yields, propagate crop pests, and pose anobstacle for planting the next crop. Disposal of excess cropresidue, especially in the highest yielding counties, is aproblem. Field burning, the historical and most economicalsolution is no longer a socially acceptable. Over the past decade, power demand in Washington, Oregon, andIdaho has risen 24 percent while the regions capacity togenerate power has increased by only four percent, accordingto the Northwest Power Planning Council. Costs of buyingenergy when demand has exceeded supply have skyrocketed forutilities. And as a result, ratepayers have seen an escalationin electric bills. The energy crisis in California exacerbated already short supplies in the Northwest.Depending on the season, Washington and Oregon import andexport power from California. The 2019 draught left theNorthwest with low levels of snow pack to feed rivers andreservoirs for hydroelectric generation. A total of 100metric tons (dry basis) of rain washed rice straw was collectedfrom two commercial field sites in the Sacramento Valley during7 / 16the spring of 1998 after 7 months exposure and 717 mm cumulative precipitation. Of this, 67 tones were hammer milled and then dandified through a modified forage cumber. Half of this material was blended with a baseline wood fuel and burned in a stoker-fired traveling grate boiler; the other half was blended with an agricultural/urban wood fuel and burned in a circulating fluid bed (CFB) boiler. The remaining 33 t were hammer milled and blended with rice hulls and burned in a suspension-fired boiler. For comparison, tests were also conducted in each facility using the baseline blending fuels (wood or rice hulls) without the rice straw. Because of problems feeding the suspension-fired boiler, several experiments were carried out at this facility. At the other two facilities, the straw blends were burned in single experiments without interruption. During testing, samples of fuel, bottom ash, and fly ash were collected at regular intervals. The stoker-fired traveling grate boiler was one of three identical boilers providing steam to a common header supplying three turbo-generators totaling 50 MWe net output. The CFB boiler was a single unit with a 25 MWe net output. The suspension-fired boiler was also a single unit with a 26.5 MWe net output. The tests were carried out under rated load conditions with the---------------------------------------------------------------最新资料推荐------------------------------------------------------ exception of the suspension-fired unit. In that case, problemswith the bag just before the first straw test prevented operating above 20 MWe. All tests, including baseline, were conducted at 20 MWe even after the bag was fixed. The furnaceexit gas temperature (FEGT) was therefore lower than at peakload. No soot blowing occurred during testing. Depositprobes show that the specific rate of deposit formation decreased when firing straw. The rates are expressed on an ironfree basis to remove the effects of differing corrosion ratesand different amounts of probe steel in the deposits. Althoughthe amount of straw available was limited, and the duration ofthe tests were short (5 to 7 h), visual observations of theheater are consistent with probe results in that no change inthe existing deposits occurred. The decrease in depositionrates for the straw/wood blends are substantial, and are accompanied by declines in deposit alkali concentrations. The technology for burning straw for power is not new. Whileno straw-burning electrical generating facilities exist in theUnited States, several European countries, including Denmark,the United Kingdom, and Spain, do have large, efficient plants, burning 2 million tons of straw per year. What Has9 / 16Been Done A Washington State University study attempted todetermine how much straw is available, the total cost of gettingstraw from the field to point of incineration; the mostcost-effective methods of doing that; the costs of building andoperating a straw-power electrical co-generating plant, andthe break-even pricing of electrical power produced. Impact The study found that Eastern Washington grain growersproduce about 3 million tons of straw that is economicallyfeasible to harvest. That much straw has the potential forproducing 400-425 megawatts of energy each year. While thecost of electrical production about 8.5 cents per kwh. wouldbe considerably higher than either hydro or nuclear sources,blend pricing, environmental benefits and the volatile energymarket still make straw-to-energy worth considering. Blend pricing refers to how electricity suppliers price theirproducts. Though power produced from straw may be uneconomical when priced at the margin, blended with lower-costsources, such as hydro and nuclear, may make it economicallyfeasible, especially when energy supplies from lower-costsources are limited and in short supply. The recent volatilityof the energy market may provide additional incentive. Researchers concluded that cooperatives might provide the---------------------------------------------------------------最新资料推荐------------------------------------------------------ appropriate organizational form of business needed to initiate this straw-to-energy conversion. As such, those producing the straw would not only benefit from the disposal of this by-product, but would stand to benefit from the sale of the straw and the management/ownership of the resultant off-farm enterprise. Preliminary full scale experiments with leached rice straw were carried out successfully in a stoker-fired traveling grate boiler. This paper describes the results of additional full scale tests for three separate biomass power technologies: stoker-fired traveling grate, circulating fluid bed, and suspension-fired boilers. 电火花加工法对加工超韧性的导电材料(如新的太空合金)特别有价值。