KISSsoft软件齿轮基础培训非常全面

- 格式:pdf

- 大小:9.29 MB

- 文档页数:178

kisssoft齿轮传动参数设计

齿轮传动是工程领域中常见的一种传动方式,常用于轴、传动器和减速器中。

而要进行齿轮传动的设计,KISSsoft是当前比较常用和先进的齿轮传动计算软件之一。

下面介绍KISSsoft齿轮传动参数设计的基本步骤:

第一步,输入传动参数。

首先需要输入齿轮传动的一些基本设计参数,例如齿轮的齿数、模数、齿宽、压力角等。

同时还需要确定齿轮材质、润滑方式、工作温度等参数。

第二步,进行齿轮计算。

在输入完基本参数后,KISSsoft会自动进行齿轮参数的计算,包括模数、模数系数、齿距、齿顶径、齿根径等参数。

第三步,进行齿轮校验。

齿轮校验常常是齿轮传动设计中最重要的一步,它包括齿面接触应力、齿面弯曲应力、寿命和齿轮噪声等方面的校验。

KISSsoft可以快速对齿轮进行校验,计算出齿轮的寿命和工作安全系数等参数。

第四步,进行齿轮优化。

如果齿轮设计不符合要求,需要对其进行优化。

KISSsoft提供了多种优化方法,可以优化齿形、齿距、润滑条件等方面,以提高齿轮的工作性能。

第五步,输出齿轮参数。

当齿轮传动设计完成后,可以将计算结果输出为机加工图和技术参数表格等格式,方便加工和使用。

总之,KISSsoft是一种功能强大、使用方便的齿轮传动计算软件,它可以帮助工程师快速设计和校验齿轮传动,提高齿轮的工作性能和寿命。

齿轮传动设计者在使用KISSsoft进行齿轮传动参数设计的过程中,应严格按照各设计步骤进行,以确保齿轮传动的正常工作。

验证圆柱齿轮的KISSsoft中文基础教程KISSsoft教程系列圆柱齿轮的计算 1. 设计任务本系列教程将介绍如何对已知数据的齿轮通过KISSsoft软件进行详细的分析和计算从而得出一系列的结果。

因此圆柱齿轮完整计算需要规定以下几个方面 1 所需原始的数据输入KISSsoft重新计算 2 按照DIN3990标准规范 3 根据实际要求创建文档的级别标准。

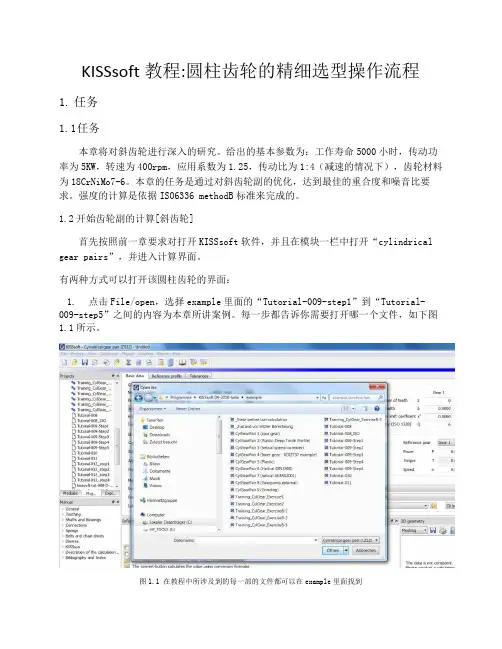

1.1 输入原始数据对于随后进行的数据输入说明请参阅本教程系列的第二章内容 1.1.1 载荷参数性能功率P 3.5 kw 驱主动速度n 2500 1/min 小齿轮 1 应用系数KA 1.35 寿命周期 750 h 1.1.2 几何法面模数mn 1.5 mm 斜齿螺旋角β 25 ? 度法面压力角 20 ? 度齿数 16/43 中心距a 48.9 mm 变位系数x 小齿轮1 0.3215 齿宽b 齿1/齿2 14/14.5 mm 1.1.3分度齿廓齿根高系数hfP 齿根半径系数齿顶高系数haP 齿1 主动轮 1.25 0.3 1.0 齿2 1.25 0.3 1.0 1.1.4附加数据材料 ? 材料硬度弯曲疲劳强度极限齿面接触疲劳极限齿1 主动轮 15 CrNi 6表面硬化 HRC 60 430N/mm2 1500N/mm2 齿2 15 CrNi 6 表面硬化 HRC 60430N/mm2 1500N/mm2 润滑脂润滑微量润滑油 GB00 80?C 基圆正切长度公差范围: 齿1 小齿轮 3 数最大基圆正切长度 Wkmax 最小基圆正切长度 Wkmin 齿11.782mm 11.758mm 齿2 6 25.214mm 25.183mm 质量Q DIN3961 8/8 2主要轮齿修形方法轮齿齿面轮廓修形线性和抛物线形接触方式正常不发生改变或不正确啮合小齿轮轴的性质图1.1 小齿轮轴的应变图 ISO 6336 图片13a I53mmS5.9mm dsh14mm 2. 解决方式 2.1 启动程序通常在注册以及安装之后通常的步骤有开始gt程序gtKISSsoft 04-2010gtKISSsoft才可以启动KISSsoft软件以下为整个操作的截图2.1 2.2 计算方式的选择在树型窗口下有一个活动的Module模块选择双圆柱齿轮副这样一个命令。

KISSsys Tutorial:Gear transmission with planetary differentialStructure of the tutorial The tutorial has two parts to be studied in this order. Introduction explains the most important points in this modeling task and introduces how to start KISSsys. Building a model explains techniques how to build a KISSsys model of a complex gearbox with sevelra power path possibilities. During the study of this tutorial, questions may arise or problems may occur. The KISSsoft customer support can be reached through the address and phone number given above.K I S S s y s t u t o r a i l : T r a n s m i s s i o n w i t h p l a n e t d i f f e r e n t i a l1Table of contents1 Table of contents (2)2 Introduction (4)2.1 Summary of the most important points (4)2.2 Systematicprocedure (4)2.3 Errata and remarks (4)task (4)2.4 ModellingKISSsys (5)2.5 Starting2.6 Selection of the project directory (5)2.7 Opening an empty KISSsys model (6)templates (6)the2.8 Loadingmodel (7)3 Buildingastructure (7)3.1 Treeelements (7)3.1.1 Machine3.1.2 Loads due to overlaid shafts (7)3.1.3 Connections (9)flow (12)3.1.4 Power3.1.5 Adding KISSsoft analysis modules (14)3.2 Input of Gear-, shaft- and bearing data (15)data (15)3.2.1 Gear3.2.2 Shafts and bearings (16)View (19)4 3D4.1 Adding 3D view in the tree structure (19)4.2 Location of the shafts (19)4.2.1 Positioning of the shafts s1a and s1b (19)4.2.2 Positioning of the shaft s2 (19)4.2.3 Positioning of the shaft s6 (20)4.2.4 Positioning of the shaft s3 (20)4.2.5 Positioning of the shaft s4 (20)4.2.6 Positioning of the shaft s5 (21)4.2.7 Positioning of the planet spindle (21)4.3 Work with the 3D Viewer (21)4.3.1 Inside diameters of the gear wheels (21)4.3.2 Color and transparency (22)4.3.3 Visualizing bearings in a shaft bore (22)4.4 Insert data from CAD system (23)5 Changing of gears (24)5.1 Background Information about clutch elements (24)5.2 Applied in the current example (24)5.3 Start of the function (26)Interface (27)6 User6.1 Input of the power (27)6.2 Execute buttons for function in the User Interface (28)model (29)the7 Completing7.1 Calculation of the bearing speed in system with overlaid shafts (29)7.2 Input of the speed ratio for front and rear drive (30)7.3 Input of efficiency (31)7.4 Settings to calculation methodology (32)tooth contact of a gear wheel (32)multiple8 Calculationof8.1 Remarks (32)8.2 Calculation on-road and off-road gear selection (32)8.3 Functionality (33)9 Annex A, ...Set Speed“ (35)9.1 Code (line numbers are not part of the code) (35)9.2 Clarification (35)2Introduction2.1Summary of the most important points1)Where two or more shafts overlap, the bearing load from the around shaft must be transferred by a forceelement to the shaft which is under it. (see chapter 3.1.2)2)For this transfer of bearing loads from one coaxial shaft to the other, …call ‘OnCalcTorque’ duringcalculation of torque” has to be activated. (see chapter 7.4)3)Further, the relative speed of the bearings between overlaid shafts must be calculated as the differencein speed between bearing outer ring and bearing inner ring. (section 7.1)4)The speed at the two output shafts (front and rear axle) are placed with one to another in reference.Therefore the speed at one output shaft has to be set as "Constraint=Yes" and an expression is set to compute one speed (those of the front axle) from the other (the rear axle). In addition, an iteration is necessary for the calculation of the relative speed) ( section 3.1.2 and 7.1)5)"Iteration for torques” and “speed with damping" must be set to execute the iteration. (Section 7.4).2.2Systematic procedureThe following steps are involved when building a KISSsys model:1.Planning: Naming, range and goals of the model2.Insert mechanical component in the tree structure (red Icons)3.Connect mechanical component to each other (grey Icons)4.Define sources of power flow5.Add KISSsoft calculation to the mechanical components (blue Icons)6.Add 3D graphic, and position elements in the graphic7.Add tables / User Interfaces8.Program own functions9.Tests, debugging2.3Errata and remarks1)If questions or difficulties arise during the tutorial, KISSsoft Hotline can be used for assistance (e-mailaddress, tel. no. etc. see front of document).2)The planetary differential used for this example in practice would be a double planet planetary wherethe sun and the planet carrier have the same sense of rotation. However, to prevent the example becoming too complex, a simple planetary train is used. Therefore both outputs rotate contrary to each other.3)The original idea for this tutorial had planned a differential lock between the annulus and the planetcarrier. This clutch is called c3. In reality it will be not used although in the tutorial it is described. It is recommended to proceed exactly according to the tutorial instructions (i.e. the clutch c3 is to be modeled although this is not used).4)An error occurs with the nomination of the forces on s2 due the overlap of shaft s6.2.4Modelling taskA transfer gearbox for a 4x4 off-highway vehicle is to be modeled. The transmission possesses an on- and off -road gear as well as a lockable epicyclic differential acting as a longitudinal differential. A part of the power is continually taken off over a PTO. The bevel gear differentials in the axles are not modeled. The unlocked gears z1 and z2 on the input shaft clutches can be switched on or off.Figure2.4-1 Sketch of the gear train to be modeledFollowing names and characters are useds = shaft; z = gear; c = clutch/couplings; b = bearing (b1: left side bearing, b2: right side bearing) red arrow is power input respective power outputred arc is power transmitted through virtual coupling c32.5Starting KISSsysFirst, a project folder has to be created. Then, KISSsys 03/2008 is to be started and the intended folder is chosen as project folder.Using “Options”, activate the administrator mode. Then, the templates should be opened using “File/Open templates…”.Make sure the latest Patch version is installed on your computer. (Download from www.KISSsoft.ch)2.6Selection of the project directoryKISSsys works with so called ‘projects’ to manage the files. These are listed directory names, in which the KISSsys model and pertinent KISSsoft files are stored. Before a model can be opened in KISSsys, a directory must be defined in which the KISSsys model is to be stored. Therefore a new appropriate directory name has to be created in the main directory KISSsys before starting to model.Through the button in the red marked circle the new directory can be selected. Please notice, the appropriate directory shows up only if you have created the directory as described in the sentence above. In our case: C:\Programme\KISSsoft 03-2008\KISSsys\tutorial-003. After the selection of the directory in the Windowsdialogue with "opening" is to be confirmed, press “open” and KISSsys is launched.Figure2.6-1 Selection of the project directory2.7Opening an empty KISSsys modelKISSsys starts now with an empty model. As a first step, the "administrator" mode must be activated under themain menu "Options".Figure2.7-1 Activate the administrator mode under “Estras” in the main menuIf the option "administrator" can not be selected, then the KISSsys license is missing. In this case contactKISSsoft AG.2.8Loading the templatesAs a first step when creating a new KISSsys model, the templates are to be imported through the menu “File”,“Open templates…”, “templates.ks”. In the templates, all elements are now listed which can be used inKISSsys:Figure2.8-1 Element library … Templates“.After having imported the templates, the model can now start to be built.3Building a model3.1Tree structureIn a first step all existing mechanical components must be defined in a tree structure. It is highly recommended to name gears, shafts, bearings and couplings in such a way as shown in the illustration down. User can define first shaft (e.g. “s1” with bearings “b1 and “b2”) and then copy it to avoid adding all bearings one by one.3.1.1Machine elementsFigure3.1-1 Shafts, Shafts with bearings, shafts with bearings /couplings, elements for modeling epicyclic gear trains The same names can be used several times for different mechanical components, as long as the mechanical components are in a different path of the tree. Please note all bearings are called "b". The left hand bearing is "b1"; the right hand bearing is "b2".The following is important when modeling an epicyclic gear train:1)The planet is supported only by one bearing. I.e. on the shaft …sp“ there is only one bearing…b1“(…kSysRollerBearing“ from the templates) placed.2)The planet carrier needs a special coupling: ”kSysPlanetCarrierCoupling“. Do not mix up this elementwith …kSysCoupling“. This special coupling should be named as …cc“ and will be positioned on the shaft s5. This element is necessary to rotate the planet in the world coordinate system.After these two elements are added, the tree structure looks like in illustration 3.1-1 (above right).All spur gears must be arranged on the respective shafts, the tree structure looks as follows in Figure3.1-53.1.2Loads due to overlaid shaftsForce elements on the shafts “s1” and “s2” have to be added. These force elements are to lead the bearing loads of “s1a” and “s1b” as well as “s6“ in each case on those under it lying shaft (s1 and s2). From the templates the element "kSysCentricalLoad" is used. Four forces are used in total on “s1”, on “s2” two forces are applied. The names of these forces should identify the origin of the force.The names of the forces expose themselves together:For example …f_s1ab1“:…f“ for force…s1a“ marks the shaft that the force is taken over…b1“ marks the bearing that the load is taken overFigure 3.1-2 Forces due to the overlaid shafts on s1 and s2The force components of the inserted forces must be connected with the components of the bearing loads. To do this the right mouse button must be clicked on a force (e.g. f_s1ab1), whereupon the "characteristics" (Properties) appear and must be selected, and after selecting “Fx” under “expression” the following text has to be inserting: GB.s1.s1a.b1.Fx.The expression makes sure the load on the shaftaffecting the load on the other shaft (respectivelytheir x-component) equals the x-component of thebearing load b1 on s1a.The appropriate expressions must be registered alsofor Fy, Fz, Tx and TzFor Fy: GB.s1.s1a.b1.FyFor Fz: GB.s1.s1a.b1.FzFor Tx: GB.s1.s1a.b1.MxFor Tz: GB.s1.s1a.b1.MzThese linkages of the forces must be done for allforces provided:f_s1ab1, f_s1ab2, f_s1bb1, f_s1bb2, f_s6b1, f_s6b2.Figure 3.1-3 Linking force componentAdd as well automatic positioning for the forces on the shaft according to the positions of the bearings. For thisuse functions l_p() to set positions.The expression makes sure the load position on the shaft isequal to the position of the mating bearing (respectively theiry-component).This function looks for reference element and point on parentelement and converts coordinates. Finally only y-direction istaken (*{01,0})l_p(GB.s1.s1a.b1,{0,0,0})*{0,1,0}The appropriate expressions must be registered also for allother forces.Figure 3.1-4 Linking force positionsFinally add gear components to the model.Figure3.1-5 Tree structure and KISSsys sketch with mechanical components3.1.3ConnectionsIn the next step the following connections are defined:1)Connections of the shift clutches for the road gear (c1, c1): It uses "kSysCouplingConstraint" from thetemplates.Action:First copy from the templates "kSysCouplingConstraint" and paste it to the tree structure within the group "GB". The name will be specified with "C1", thus it is clear which clutches are connected (namely c1 on s1 with c1 on s1a). In a second step the clutches which can be connected are to be selected. In addition it must be defined whether the clutch is closed (activated) or open (not activated).Figure3.1-6 Definition of a clutch connection, here for road course2)Connect the shift clutches for the off road gear (c2, c2). This clutch will be open.(…Activated=No“)because both gears can not be closed at the same time:Figure3.1-7 Definition of the clutch for off road course3)Connect both clutches c3, differential lock. The clutch will be open (…Activated=No“):Figure3.1-8 Connection between clutches c3After all clutches are connected within the transmission, the individual gears must be connecting together. For the spur gears, the type "kSysGearPairConstraint" is necessary. The planets need the type “kSysPlanetaryGearPairConstraint " two times. One where the sun wheel connects the planet, the other the planet connects the annulus. The connections are copied from the templates into the tree structure, below the group of "GB":Gear pair gp1 Gear pair gp2Gear pair gp3 Gear pair gp4Figure3.1-9 Definition of gear pairs.Gear pair sun zs between Planet zp “sp”Gear pair planet zp between annulus zr “pr”Figure3.1-10 Definition of a planet gear connection in the systemThe tree structure with the connections defined in the KISSsys sketch should look now as follows:Black line connections: active / close connectionsGrey line connections: inactive / open connectionsFigure3.1-11 Tree structure and KISSsys sketch with connections3.1.4 Power flowThe definition of the power flow in the gearbox is through the element …kSysSpeedOrForce“. This element is to be copied from the templates and pasted four times directly into the tree structure (not under …GB“)During the power input "Input" speed and the torque are given. Both values are signed sizes. If the product of the two signs is positive, then the power is positive, i.e. it concerns a positive input power.Figure3.1-12 Definition of Input power …Input“(Motor)The PTO torque is set to 10Nm (acceptance for this example). The direction of rotation is counter clockwise. The number of revolutions is therefore negative. The torque has to be entered positively thereby the power output becomes negative.Figure3.1-13 Definition of the power take off (PTO)Rear-wheel drive RWD (OutR)As a consequence, number of revs and torque follows by the input data and the type of transmission. No values are given.Figure3.1-14 Definition of the RWDFront wheel drive FWD (OutF)The condition for the front wheel drive is defined as follows:Front axle and rear axle turn with the same speed, but contrary. This condition will be still specified in section 7,2.Thus the number of revolutions at this output (the front axle) is the same as from the number of revolutions of the output “OutR", therefore "speed of constrained=yes" must be set.With the right mouse-click on the power output "OutF" and the choice in "Properties" of "speed", an expression for the speed can be defined at this output. Enter in the field "Expression":"-OutR.speed". This guarantees that the speed at the output is equal the speed of the shaft s5, but in opposite direction of rotation.Figure3.1-15 Definition of the FWDNow the kinetic calculations can be started using right mouse-clicks on menu, selection of "Calculate Kinematics". (Section 7.4 must also be considered). After a Refresh, the sketch looks as follows:Figure3.1-16 KISSsys model with power flow after execution of kinematics analysis3.1.5Adding KISSsoft analysis modulesNext step is to introduce the KISSsoft analysis modules. These are copied from the templates. KISSsoft analysis modules for shafts, bearings and gears are needed. The gear pair and planetary gear analysis are arranged directly below the appropriate connection with the same name. The shaft and bearing calculations are inserted within the appropriate shaft computation.The bearing calculation "Bearing2" is copied from the templates. The index "2" means that altogether two antifriction bearings are computed. Note: for the planet “Bearing1" must be used from the templates since the planet is stored on the spindle only through an antifriction bearing. Bearing calculations can be also done directly in shaft module, but in cases when bearings are between two shafts separate calculation modules should be used to set speed for bearing correctly (relative speed between two shafts).Figure3.1-17 Tree structure with computations (left), and templates used (right)3.2Input of Gear-, shaft- and bearing data3.2.1Gear dataThe following teeth data in Figure 3.2 is used in this example. In addition double-click on the computations (blue Icons) in the tree structure. After entering the design data, the input in each case has to be confirmed with"calculation F5". Afterwards, close the KISSsoft window with "exit" (cross in the right upper corner).Figure3.2-1 Input data gear pair gp1 Figure3.2-2 Input data gear pair gp2Figure3.2-3 Input data gear pair gp3 Figure3.2-4 Input data gear pair gp4Figure3.2-5 Input data for epicyclic drive train3.2.2Shafts and bearingsPosition of elements cIn: y = 5 mm c1: y = 70 mm c2: y = 140 mmPosition of bearings: y = 15 mm y = 170 mmPosition of gear z6: y = 190 mmFigure3.2-6 Input data shaft s1Position of gears: z2 y = 50 mm z4 y = 120 mmPosition of bearings: y = 15 mm y = 195 mmFigure3.2-7 Input data shaft s2Position of the clutches: y=28 mm for s1a, s1b and s6Position of the gear 15 mm Position of bearings 5 mm and 25 mmFigure3.2-8 Input data s1a, s1b, s6Coupling: cc y = 5mmcrOut: y = 190 mm c3: y = 70 mmBearings 90 mm and 170 mmFigure3.2-9 Input data s5coupling cfOut: y=10mm, zs: y=190Bearings 30 mm and 150 mmFigure3.2-10 Input data s4Figure3.2-11 Input Planet pin (sp)To calculate shaft with only one support it may be necessary to activate calculation with bearing internal geometry.z5: y =10mm zr: y = 20mmclutch c3: y=65 mm b1: y = 30 mm b2: y = 58 mmFigure3.2-12 Input data s343D View4.1Adding 3D view in the tree structureFrom the templates, the 3D view "kSys3Dview" is inserted into the highest level of the tree structure. Select “show" using right mouse button by touching the insert function. All mechanical components are still in the same position because their position in the working sheet is not defined. Therefore, the next step will be to arrange the positions of the shafts in the coordinate system.Figure4.1-1 3D view of the gear train model4.2Location of the shafts4.2.1Positioning of the shafts s1a and s1bThe shafts “s1a” and “s1b” are positioned in reference to shaft “s1”. The shafts have a radial distance of zero, and axial length of 35mm and 105mm for “s1a” and “s1b” respectively on shaft “s1”.Figure4.2-1 Positioning of the shafts s1a and s1b to s14.2.2Positioning of the shaft s2The shaft s2 is positioned relative to shaft s1. Both shafts s1 and s2 end at the same horizontal X-position. The distance between the two shafts is equal to the centre distance (a) of the gear pair gp1. (or gp2; or gp4)Figure4.2-2 Positioning of the shaft s24.2.3Positioning of the shaft s6The shaft s6 is positioned relative to shaft 2 (s2). The radial distance is zero. The relative Y-position to the shaft s2 is delta y=180mm.Figure4.2-3 Positioning of the shaft s64.2.4Positioning of the shaft s3This shaft must be placed such that both gears “z5” and “z4” are touching each other through both centre lines of the facewidth. Shaft “s3” has to be placed relative to “s2”. The distance is exactly the centre distance between gear pair “gp3”. The y-position is defined by the position of both gears. The location of the gears on the shaft itself is stored in the variable …position“. Furthermore, the shaft “s3” is located vertically below the shaft “s2”. (phi = -90 deg)Figure4.2-4 Positioning of the shaft s34.2.5Positioning of the shaft s4The shaft “s4” is positioned in reference to shaft “s3”. Both are concentric to each other. The relative Y-position must be chosen in a way that the centre-line of both the gear “zr” on the shaft “s3” and gear “zs” on the shaft “s4” have the same absolute Y-value.Figure4.2-5 Positioning of the shaft s44.2.6Positioning of the shaft s5The shaft “s5” is positioned in reference to the shaft “s3”. They have the same centre line. The relative y position must be selected in such a way that “zp” gear (planet) and “zr” gear (annulus) are on the same absolute y position. The right shaft end of the planet spindle is in the same position as the left shaft end of “s5”. The distance from the centre of the planet to the end of planet spindle is 5mm.Figure4.2-6 Positioning of the shaft s54.2.7Positioning of the planet spindleThe planet spindle is positioned in reference to the shaft “s3”. The planet and the annulus have the same Y-position. The centre distance is given through the KISSsoft gear calculation of the gear stage.Figure4.2-7 Positioning of the planet spindlePress “Refresh” button on menu to see all components places correctly in the space.4.3Work with the 3D Viewer4.3.1Inside diameters of the gear wheelsThe inside diameters of the gear wheels should be set equal to the outside diameter of the respective shaft. For all gear wheels, except the internal gear, the variable “di” should have the following text inserted in the field “expression”:Figure4.3-1 Expression for (i)This supplies the outside diameter of the shaft at the place where the gear part is located.For the internal gear zr, the value for "di" must be inserted manually (in the field "value") equal to the inside diameter of the shaft, but negative:Figure4.3-2 Insert of …di“ by the internal gear zr4.3.2Color and transparencyA variable “kSys_3DColor” and “kSys_3Dtransparency” can be affixed to the mechanical components (gear wheels "z", bearings ”b”, shafts "s" and clutches "c"). This will change the colour and transparency of the selected element. Numerical values 0-255 change the colors, while for transparency between select obscure (0) to transparent (1). User can also use setting functionality from the menu to set colors and appearance for the components.Figure 4.3-3 3D graphic settings4.3.3Visualizing bearings in a shaft boreThe following trick must be used to set correct visualization for the bearings defined according to internal geometry. For both bearings on the shafts “s1a”, “s1b” and “s6” from the variable "d" under “Properties” expression must be deleted for each case.The expression from “d”need to be deletedFigure4.3-4 Necessary …Trick“ for visualizing bearings in a shaft boreAfter a refresh command, the 3D view looks like the following:Bearing: green.Shaft with the non-locater bearing: grey, obscure.Underlying shaft: grey, transparentAlso shown: The local coordinate system from thesame shaft.Figure4.3-5 Correct view of the bearing4.4Insert data from CAD systemDepending upon version of KISSsys *.sat, *.iges or *.step data from any CAD system can be imported. In addition, "kSysCasing" has to be copied from the templates into the tree structure. In this example, four individual CAD data records are read in, and four KISSsys elements of type "kSysCasing" are created. They are called in this example "Wheel1" to "Wheel4": The file attached in this example is called “tut-003-CAD-data.igs”Figure4.4-1 Tree structure with inserted elements for the integration of the CAD data (left), dialogue to “kSysCasing” elements (right)If the dialogue window is open by the right mouse button, then under “Type”” Read file” must be selected. In the field "file name" the complete file name inclusive path is to be indicated if file is not in located in the project folder. Positioning of the Wheels can be done manually entering in the Properties and changing position values.After a refresh the 3D view can look as follows:Figure4.4-2 3D view of the transmission gearbox with imported geometry5 Changing of gears5.1 Background Information about clutch elementsFor the clutch connection the function:setConfig(Activation,Torque constrain)There are the following usual cases:• Clutch is closed, no slip, torque is calculated: setConfig([TRUE, 0], FALSE)• Clutch is closed, slip and torque is given: setConfig([TRUE, slip], [TRUE, moment]) • Clutch is open, no torque: setConfig(FALSE, FALSE)• Clutch is open, torque is given: setConfig(FALSE, [TRUE, moment])For a transmission with two gears, with a given torque at the output in the first gear and given torque at the input by the second gear, a changing gear function can look as follows: (Note! This is only example code)IF gear=1 THEN Coupling1.setConfig([TRUE, 0], FALSE); Coupling2.setConfig(FALSE, FALSE); Input.setConfig(TRUE, FALSE); Output.setConfig(FALSE, TRUE); ELSIF gear=2 THEN Coupling1.setConfig(FALSE, FALSE);Coupling2.setConfig([TRUE,0], FALSE);Input.setConfig(FALSE, FALSE);Output.setConfig(TRUE, TRUE);ENDIFCheck if gear 1 is connected. Set clutches according to the gear selection Set boundary conditions If gear 2 selected do settings according to that 5.2 Applied in the current exampleThe function for changing gears should be contained in a table "Settings". First from the templates the table "user interface" must be copied into the highest level of the tree structure. The table has to be named "Settings". Using the right mouse button, the size of the table can be defined under "dialogue". The table can be visualized by selecting "show". Using the right mouse-click under "Settings" in the tree structure, on selection of "new variable" a further variable with the name "SetSpeed" of the type "function" can be insert.By the right mouse-click on "Settings" and the selection of …Properties", the following window opens. Now the function editor can be called by the right mouse-clicks on "set speed" and the selection by "Edit".Further, a variable "OnOffRoad" of the type "real" is to be added. This will describe the momentarily selected gear. If it is 0, then the on-road gear is active, and if 1 then the off-road gear is engaged.Figure5.2-1 Properties (different variables) under …Settings“. NOTE: the new variables OnOffRoad, Set Speed appeared.Figure5.2-2 Function …Set Speed“ (NOTE:more details about this in Annex A)The function "CADH_VarDialog" generates a dialogue in which can be defined whether the on- or off- road gear is selected. The dialogue supplies an array of "res" as result. Zero elements into "res" is 1 (or TRUE) if the dialogue is confirmed using "OK", 0 (or FALSE) if the dialogue is closed with "CANCEL". The first element of the array corresponds to the selection made. If "on-Road" is selected then 0 is returned, otherwise "off Road" is selected and 1 is set.The first “IF” condition examines if the dialogue was closed with "OK". After this the selection is put into the variable “Settings.OnOffRoad”. If "on-Road" was selected, the clutch “C1” is closed, “C2” is open. If "off Road" was selected, the clutch “C2” is closed, and “C1” is open. Next, the kinematics calculation is called to calculate new power flow. The function can still be extended so that the open clutch in the 3D diagram is translucently represented, the closed clutch obscurely:Figure5.2-3 Function …SetSpeed“。

kisssoft教程

口碑软件是一款广泛应用于机械传动系统计算与分析的工具,它可以帮助工程师进行齿轮传动的设计和优化。

本教程将介绍如何使用KISSsoft软件进行齿轮设计。

第一步是创建一个新的项目。

在菜单栏中选择“文件”>“新建项目”,然后填写项目名称和文件夹路径。

单击“确定”按钮创建新项目。

接下来,我们需要输入齿轮的基本参数。

在菜单栏中选择“数据”>“齿轮”,然后填写齿轮的齿数、模数、压力角等参数。

点击“确定”按钮保存并关闭。

现在,我们可以开始进行齿轮系统的计算和分析。

在菜单栏中选择“计算”>“齿轮系统计算”,然后选择所需的计算类型,例如齿轮传动效率、载荷分析等。

输入所需的参数并点击“确定”进行计算。

完成计算后,我们可以查看计算结果。

在菜单栏中选择“结果”>“计算结果”,然后选择所需的结果类型,如载荷分布、齿轮精度等。

KISSsoft将显示相应的结果图表和数据。

最后,我们可以对齿轮系统进行优化。

在菜单栏中选择“优化”>“参数优化”,然后选择所需优化的参数和范围。

KISSsoft 将自动进行参数优化,并显示优化后的结果。

通过这些简单的步骤,您可以快速上手使用KISSsoft软件进行齿轮设计和优化。

祝您成功!。

KISSsoft教程:圆柱齿轮的精细选型操作流程1.任务1.1任务本章将对斜齿轮进行深入的研究。

给出的基本参数为:工作寿命5000小时,传动功率为5KW,转速为400rpm,应用系数为1.25,传动比为1:4(减速的情况下),齿轮材料为18CrNiMo7-6。

本章的任务是通过对斜齿轮副的优化,达到最佳的重合度和噪音比要求。

强度的计算是依据ISO6336 methodB标准来完成的。

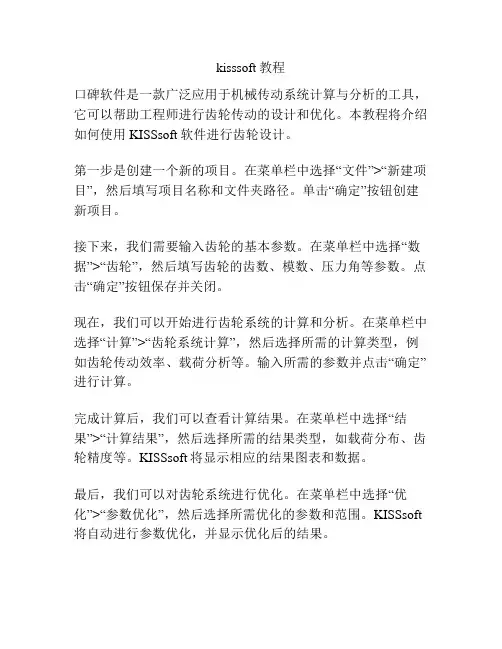

1.2开始齿轮副的计算[斜齿轮]首先按照前一章要求对打开KISSsoft软件,并且在模块一栏中打开“cylindrical ge ar pairs”,并进入计算界面。

有两种方式可以打开该圆柱齿轮的界面:1.点击File/open,选择example里面的“Tutorial-009-step1”到“Tutorial-009-step5”之间的内容为本章所讲案例。

每一步都告诉你需要打开哪一个文件,如下图1.1所示。

图1.1 在教程中所涉及到的每一部的文件都可以在example里面找到2. 在软件project 一栏中也可以直接找到相应的文件,如图1.2所示。

图1.2 软件中自带的教程同步案例2.齿轮副的粗略选型2.1 开启粗略选型的功能KISSsoft 考虑到需要输入的数据比较多,将一些基本数据参数(齿轮必须)放到一个对话框中,并且要用户必须对其进行输入。

如图1.3所示如下操作。

图1.3 粗略选型功能打开方式快捷按钮接下来需要你去输入很多基本参数,比如:传动比(使用%形式,这里采用5%),传动的功率和必须的材料。

你也可以输入定义好的螺旋角和中心距。

螺旋角是由在轴上使用的轴承来决定的,同样螺旋角的大小也是由轴承能够承受的轴向力大小来决定的。

螺旋角可以在下面步骤的fine sizing里面得到优化。

而在初始数据一栏中你只需要将输入大概的螺旋角数值就行了,直齿轮直接输入0度。

在“几何”一栏中,你还可以将在右上角的“细节”一栏中对接下来需要输入的基本参数进行一定范围设置,比如小齿轮的齿数,齿形几何大小和中心距等,如图1.4所示。

kisssoft齿轮变位系数解释说明1. 引言1.1 概述齿轮变位系数是在机械工程领域中广泛应用的一个重要参数。

它描述了齿轮啮合时,啮合点相对于齿轮基准面的位移量。

通过研究齿轮变位系数,我们可以更好地理解齿轮传动系统的性能,并做出有效的设计和优化。

1.2 文章结构本文将围绕着齿轮变位系数展开讨论,分为五个主要部分。

首先是引言部分,介绍文章的背景和目的。

然后是第二部分,讨论齿轮变位系数的定义、背景以及应用领域。

接下来,第三部分将详细介绍计算齿轮变位系数的方法与原理。

紧接着,在第四部分中,我们将分析齿轮变位系数对传动性能的影响,并着重讨论动态性能、噪声与振动以及寿命预测与可靠性评估等方面。

最后,在第五部分中给出结论总结,并提出进一步研究方向和展望。

1.3 目的本文旨在全面解释和说明kisssoft软件中齿轮变位系数的概念、应用和计算方法。

通过深入探讨这一关键参数,我们可以更好地了解齿轮传动系统,并为相关领域的工程师和研究人员提供有价值的参考和指导。

同时,我们也将对齿轮变位系数对传动性能的影响进行分析,以期对齿轮设计与优化提供实用的建议。

2. 齿轮变位系数的定义与背景:2.1 齿轮变位系数的概念:齿轮变位系数是用来描述齿轮传动中两个啮合齿轮相对于理想位置的偏移程度的参数。

在齿轮传动中,由于制造和安装误差、载荷等因素的影响,实际上啮合的两个齿轮可能存在一定程度的相对位置偏移。

这种位置偏移会导致传动性能下降、噪声和振动增加以及寿命缩短。

2.2 齿轮变位系数的应用领域:齿轮变位系数是齿轮设计和分析中一个重要的参数,广泛应用于机械工程领域。

特别是在高速、精密、大功率传动系统中,更加重视减小齿轮变位系数以提高传动效率和可靠性。

2.3 齿轮变位系数的重要性:齿轮变位系数对于确定有效载荷分布、计算接触应力、考虑弹性变形等都具有重要作用。

通过准确计算和控制齿轮变位系数,可以优化设计方案并提高传动系统的性能。

减小齿轮变位系数可以降低齿轮传动中产生的噪声和振动,提高系统的工作平稳性和舒适性。

KISSsoft高级教程:交叉斜齿轮,结合金属蜗杆和塑料齿轮,考虑长齿高制设计方法1. 概述由于交叉斜齿轮系统中蜗杆和塑料齿轮的材料不同,将会导致啮合时齿厚的分布大小不一。

金属材料的杨氏弹性模量(材料在弹性变形阶段,其应力和应变成正比例关系,标志了材料的刚性,杨氏模量越大,越不容易发生形变,符合胡克定律)为210000MPa,而塑料材料则只有3000MPa。

所以,金属蜗杆的齿厚需要缩小,而增加塑料齿轮的齿厚。

通常,在实际啮合过程中,蜗杆上轮齿断裂的可能性占到20%-40%,而塑料斜齿轮占到60%-80%。

不采用齿廓修形的情况下,蜗轮和蜗杆的齿厚分布一般为,齿厚分布均衡。

法向齿厚Sn需要缩小ΔSn(Mn*0.5),从而使蜗杆的齿厚分布占到34%,蜗轮的轮齿厚度占到66%。

塑料齿轮的齿根强度因为金属蜗杆的轮齿减小而得到巨大提升,齿数也会相应增加。

同时,齿根和齿顶圆仍然保持和先前而修改齿形时的大小。

所以,DIN3960标准采用的公式为:考虑变位系数时,在分度圆上的齿厚:Sn=Mn*(α)。

齿根圆直径:df=d+2**Mn-2h fp 。

2. KISSsoft计算过程解析在KISSsoft软件模块中,打开交叉斜齿轮模块,如图1所示。

图1 交叉斜齿轮模块将已知数据输入到基本界面,如图2、图3和图4所示。

图2 交叉斜齿轮基本数据输入模块图3 塑料齿轮长齿制齿廓设置图4 公差界面设置点击计算按钮,会出现下面错误,如图5所示:公差设置依据资料 ②请注意:在选项框中会提示怎样解决该错误的方法。

塑料齿轮计算采用DIN3990或ISO6336,需要在“特殊模块设置”窗口中点击“塑料”栏后,激活选项“允许根据DIN3990/ISO6336简单计算塑料齿轮类型”。

② ① ①塑料齿轮不适用于DIN3990或ISO6336标准。

KISSsoft软件中,为准确计算该类型系统,需要考虑塑料的S-N 曲线,其温度依靠VDI2545标准确定。

kisssoft齿轮传动参数设计

KISSsoft是一款强大的齿轮传动设计软件,它提供了各种参数设计和计算功能,方便工程师进行齿轮传动的设计和优化。

在KISSsoft中,用户可以输入齿轮的基本参数,如齿数、模数、压力角等,还可以选择不同的齿轮材料和表面处理方式,以及设置传动比和传动效率等参数,最终生成一张完整的齿轮传动设计图。

此外,KISSsoft还提供了多种齿轮传动计算功能,如齿轮强度、齿轮寿命、齿轮轴承寿命等,能够帮助工程师更好地评估齿轮传动的性能和可靠性。

总之,KISSsoft齿轮传动参数设计是一项非常实用的工具,能够大大简化工程师的设计流程,提高齿轮传动的设计质量和效率。

- 1 -。

KISSsoft教程:圆柱齿轮的精细选型操作流程1.任务1.1任务本章将对斜齿轮进行深入的研究。

给出的基本参数为:工作寿命5000小时,传动功率为5KW,转速为400rpm,应用系数为1.25,传动比为1:4(减速的情况下),齿轮材料为18CrNiMo7-6。

本章的任务是通过对斜齿轮副的优化,达到最佳的重合度和噪音比要求。

强度的计算是依据ISO6336 methodB标准来完成的。

1.2开始齿轮副的计算[斜齿轮]首先按照前一章要求对打开KISSsoft软件,并且在模块一栏中打开“cylindrical ge ar pairs”,并进入计算界面。

有两种方式可以打开该圆柱齿轮的界面:1.点击File/open,选择example里面的“Tutorial-009-step1”到“Tutorial-009-step5”之间的内容为本章所讲案例。

每一步都告诉你需要打开哪一个文件,如下图1.1所示。

图1.1 在教程中所涉及到的每一部的文件都可以在example里面找到2. 在软件project 一栏中也可以直接找到相应的文件,如图1.2所示。

图1.2 软件中自带的教程同步案例2.齿轮副的粗略选型2.1 开启粗略选型的功能KISSsoft 考虑到需要输入的数据比较多,将一些基本数据参数(齿轮必须)放到一个对话框中,并且要用户必须对其进行输入。

如图1.3所示如下操作。

图1.3 粗略选型功能打开方式快捷按钮接下来需要你去输入很多基本参数,比如:传动比(使用%形式,这里采用5%),传动的功率和必须的材料。

你也可以输入定义好的螺旋角和中心距。

螺旋角是由在轴上使用的轴承来决定的,同样螺旋角的大小也是由轴承能够承受的轴向力大小来决定的。

螺旋角可以在下面步骤的fine sizing里面得到优化。

而在初始数据一栏中你只需要将输入大概的螺旋角数值就行了,直齿轮直接输入0度。

在“几何”一栏中,你还可以将在右上角的“细节”一栏中对接下来需要输入的基本参数进行一定范围设置,比如小齿轮的齿数,齿形几何大小和中心距等,如图1.4所示。

2024年kisssoft培训计划随着制造业的不断发展和技术的不断进步,工程师们对于机械设计软件的需求也越来越大。

KISSsoft作为国际知名的机械设计软件,其应用范围广泛,功能强大,备受工程师们的青睐。

为了更好地推广和应用KISSsoft软件,提高工程师们的使用水平,我们将在2024年推出一系列的KISSsoft培训计划,以满足不同行业和用户的需求。

一、培训对象1. 机械设计师2. 设备工程师3. 模具设计师4. 机械制造工程师5. 高校机械专业学生6. 其他与机械设计相关的工程师和技术人员二、培训内容1. KISSsoft基础培训- KISSsoft软件介绍- KISSsoft软件安装与配置- KISSsoft界面与操作- KISSsoft基本功能介绍- KISSsoft实例演练2. KISSsoft进阶培训- KISSsoft齿轮设计与分析- KISSsoft轴承设计与计算- KISSsoft齿轮箱设计与分析- KISSsoft传动系统设计与分析- KISSsoft优化设计与仿真3. KISSsoft应用案例分享- 汽车行业的KISSsoft应用案例分享- 航空航天领域的KISSsoft应用案例分享- 机械制造业的KISSsoft应用案例分享- 模具设计行业的KISSsoft应用案例分享4. KISSsoft定制培训- 根据企业需求定制KISSsoft培训课程- 针对特定行业或特定项目的KISSsoft培训5. KISSsoft认证培训- KISSsoft认证考试- KISSsoft认证培训课程三、培训形式1. 线下培训- 在各地设立培训中心,定期组织KISSsoft培训课程- 邀请KISSsoft资深工程师进行面对面的培训2. 在线培训- 通过网络平台进行在线直播培训- 提供录播视频供学习者自主学习3. 企业内训- 针对企业需求,定制线下或在线的KISSsoft培训课程- 培训内容与案例可以与具体项目相结合,帮助员工更好地应用KISSsoft软件四、培训时间和地点1. 线下培训时间- 每季度举办一次KISSsoft培训课程,每次培训持续3-5天- 培训地点覆盖全国各大城市,方便学员报名参加2. 在线培训时间- 每周定期举办KISSsoft在线培训课程,每次培训持续2-3小时- 培训时间和频率根据学员报名情况灵活调整3. 企业内训时间- 根据企业需求和员工时间安排,灵活确定培训时间和持续周期- 在线内训可以根据企业需求灵活安排培训时间五、培训费用1. 线下培训费用- 培训费用包含课程培训、教材资料和培训证书- 学员报名时需支付一定的培训费用2. 在线培训费用- 在线培训费用相对线下培训更加优惠- 学员报名时需支付一定的培训费用3. 企业内训费用- 根据企业规模、培训内容和持续周期进行灵活定价- 培训费用可根据实际情况进行议价和调整六、培训师资力量1. 来自KISSsoft公司的资深工程师- 公司内部专业的技术人员将担任培训讲师- 已通过相关认证考试,具有丰富的KISSsoft软件应用经验2. 行业专家和学术界教授- 邀请行业内的专家和学术界教授进行KISSsoft培训- 提供最新的行业动态和前沿科技信息3. KISSsoft合作伙伴- 与KISSsoft的合作伙伴共同开展培训项目- 发挥各方资源优势,提供全方位的培训支持七、培训效果评估1. 考核评价- 通过KISSsoft认证考试对学员进行考核评价- 获得KISSsoft认证的学员将获得相应的认证证书2. 学员反馈- 培训结束后,对学员进行满意度调查- 针对学员反馈及时调整和改进培训方案3. 项目案例- 鼓励学员应用KISSsoft软件进行项目实践- 收集学员实际应用案例,进行培训效果跟踪评估八、培训后的支持1. 培训学员会员服务- 提供KISSsoft专业用户社区,为学员建立学习交流平台- 提供KISSsoft软件操作技术支持和问题解答2. 最新资讯分享- 定期推送KISSsoft软件最新版本、功能及技术升级资讯- 发布行业最新发展和领域应用案例分享3. 培训成果宣传- 对优秀学员和项目案例进行宣传推荐- 予以相关荣誉和奖励,鼓励学员持续提升和应用九、总结KISSsoft培训计划的实施,不仅可以提高工程师们的技术水平和应用能力,还可以推动工程设计和制造领域的技术创新和发展。

kisssoft行星齿轮设计实例

KISSsoft是一款专业的齿轮设计软件,它提供了丰富的功能和

实例来帮助工程师进行行星齿轮设计。

以下是一个关于行星齿轮设

计的实例:

在行星齿轮设计中,首先需要确定输入和输出轴的转速和扭矩

要求。

然后,根据设计要求选择合适的模数、齿数、齿轮材料等参数。

接着,进行齿轮的几何设计,包括齿形的计算、齿顶圆和齿根

圆的确定等。

在行星齿轮系统中,还需要考虑行星轮、太阳轮和内

齿圈之间的啮合关系,以及轴承的选型和布局等问题。

此外,还需

要进行强度校核、齿面接触分析、齿轮传动效率计算等工作。

最后,进行齿轮系统的动力学仿真和噪声分析,以验证设计的合理性和稳

定性。

除了以上的设计步骤,KISSsoft还提供了丰富的实例和案例,

供工程师参考和学习。

这些实例涵盖了不同类型和规格的行星齿轮

设计,涉及到不同工况和要求下的设计方案。

工程师可以通过学习

这些实例,了解行星齿轮设计的方法和技巧,同时也可以借鉴实例

中的经验和教训,提高自己的设计水平。

总的来说,KISSsoft作为一款专业的齿轮设计软件,提供了丰富的功能和实例来帮助工程师进行行星齿轮设计。

通过学习和应用这些实例,工程师可以更好地掌握行星齿轮设计的技术要点,提高设计质量和效率。