ELVALOY_AC_for_foam

- 格式:pptx

- 大小:448.66 KB

- 文档页数:25

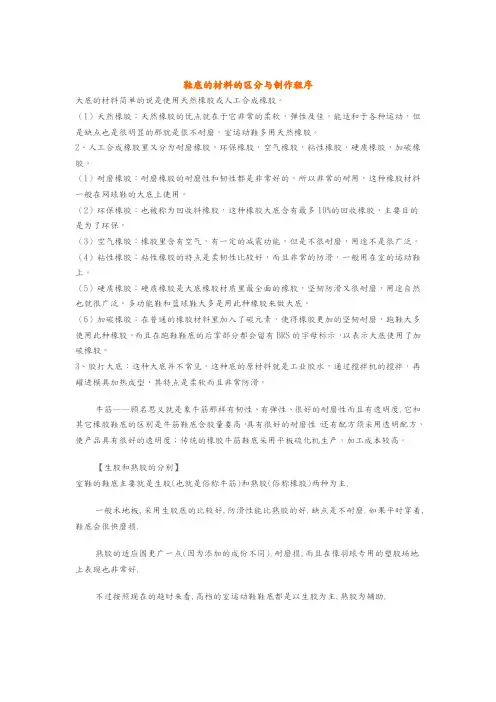

鞋底的材料的区分与制作程序大底的材料简单的说是使用天然橡胶或人工合成橡胶。

(1)天然橡胶:天然橡胶的优点就在于它非常的柔软,弹性及佳,能适和于各种运动,但是缺点也是很明显的那就是很不耐磨。

室运动鞋多用天然橡胶。

2、人工合成橡胶里又分为耐磨橡胶,环保橡胶,空气橡胶,粘性橡胶,硬质橡胶,加碳橡胶。

(1)耐磨橡胶:耐磨橡胶的耐磨性和韧性都是非常好的,所以非常的耐用,这种橡胶材料一般在网球鞋的大底上使用。

(2)环保橡胶:也被称为回收料橡胶,这种橡胶大底含有最多10%的回收橡胶,主要目的是为了环保。

(3)空气橡胶:橡胶里含有空气,有一定的减震功能,但是不很耐磨,用途不是很广泛。

(4)粘性橡胶:粘性橡胶的特点是柔韧性比较好,而且非常的防滑,一般用在室的运动鞋上。

(5)硬质橡胶:硬质橡胶是大底橡胶材质里最全面的橡胶,坚韧防滑又很耐磨,用途自然也就很广泛。

多功能鞋和篮球鞋大多是用此种橡胶来做大底。

(6)加碳橡胶:在普通的橡胶材料里加入了碳元素,使得橡胶更加的坚韧耐磨,跑鞋大多使用此种橡胶,而且在跑鞋鞋底的后掌部分都会留有BRS的字母标示,以表示大底使用了加碳橡胶。

3、胶打大底:这种大底并不常见,这种底的原材料就是工业胶水,通过搅拌机的搅拌,再罐进模具加热成型,其特点是柔软而且非常防滑。

牛筋——顾名思义就是象牛筋那样有韧性、有弹性、很好的耐磨性而且有透明度.它和其它橡胶鞋底的区别是牛筋鞋底含胶量要高,具有很好的耐磨性,还有配方须采用透明配方,使产品具有很好的透明度;传统的橡胶牛筋鞋底采用平板硫化机生产,加工成本较高。

【生胶和熟胶的分别】室鞋的鞋底主要就是生胶(也就是俗称牛筋)和熟胶(俗称橡胶)两种为主.一般木地板,采用生胶底的比较好,防滑性能比熟胶的好.缺点是不耐磨.如果平时穿着,鞋底会很快磨损.熟胶的适应围更广一点(因为添加的成份不同).耐磨损.而且在像羽球专用的塑胶场地上表现也非常好.不过按照现在的趋时来看,高档的室运动鞋鞋底都是以生胶为主,熟胶为辅助.对比没有特别技术的普通橡胶底,牛筋底(水晶底.生胶底)是比较耐磨的.至于防滑.在粗糙的水泥地上或者在光滑的木板地上.牛筋底和橡胶底没有太大分别.但在有水积的光滑地面上牛筋底是比较危险的.走路要小心,比较滑二、中底1、现在球鞋中底我想我不说很多人也都会知道,那就是PHYLON中底,和EVA中底最常见。

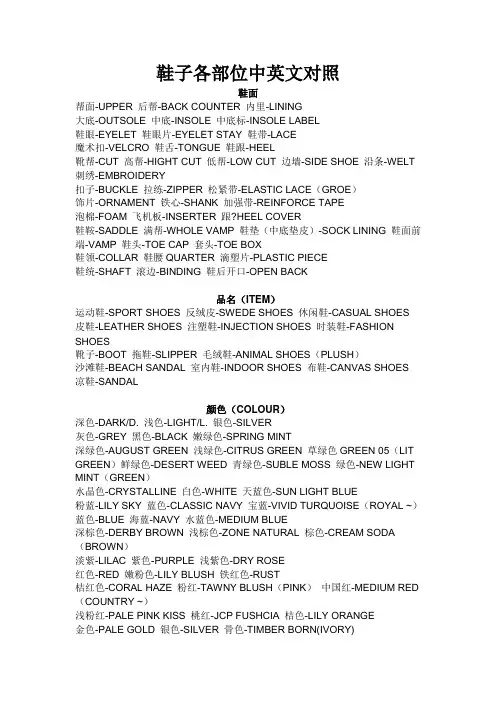

鞋子各部位中英文对照鞋面帮面-UPPER 后帮-BACK COUNTER 内里-LINING大底-OUTSOLE 中底-INSOLE 中底标-INSOLE LABEL鞋眼-EYELET 鞋眼片-EYELET STAY 鞋带-LACE魔术扣-VELCRO 鞋舌-TONGUE 鞋跟-HEEL靴帮-CUT 高帮-HIGHT CUT 低帮-LOW CUT 边墙-SIDE SHOE 沿条-WELT 刺绣-EMBROIDERY扣子-BUCKLE 拉练-ZIPPER 松紧带-ELASTIC LACE(GROE)饰片-ORNAMENT 铁心-SHANK 加强带-REINFORCE TAPE泡棉-FOAM 飞机板-INSERTER 跟?HEEL COVER鞋鞍-SADDLE 满帮-WHOLE VAMP 鞋垫(中底垫皮)-SOCK LINING 鞋面前端-VAMP 鞋头-TOE CAP 套头-TOE BOX鞋领-COLLAR 鞋腰QUARTER 滴塑片-PLASTIC PIECE鞋统-SHAFT 滚边-BINDING 鞋后开口-OPEN BACK品名(ITEM)运动鞋-SPORT SHOES 反绒皮-SWEDE SHOES 休闲鞋-CASUAL SHOES 皮鞋-LEATHER SHOES 注塑鞋-INJECTION SHOES 时装鞋-FASHION SHOES靴子-BOOT 拖鞋-SLIPPER 毛绒鞋-ANIMAL SHOES(PLUSH)沙滩鞋-BEACH SANDAL 室内鞋-INDOOR SHOES 布鞋-CANVAS SHOES 凉鞋-SANDAL颜色(COLOUR)深色-DARK/D. 浅色-LIGHT/L. 银色-SILVER灰色-GREY 黑色-BLACK 嫩绿色-SPRING MINT深绿色-AUGUST GREEN 浅绿色-CITRUS GREEN 草绿色GREEN 05(LIT GREEN)鲜绿色-DESERT WEED 青绿色-SUBLE MOSS 绿色-NEW LIGHT MINT(GREEN)水晶色-CRYSTALLINE 白色-WHITE 天蓝色-SUN LIGHT BLUE粉蓝-LILY SKY 蓝色-CLASSIC NAVY 宝蓝-VIVID TURQUOISE(ROYAL ~)蓝色-BLUE 海蓝-NAVY 水蓝色-MEDIUM BLUE深棕色-DERBY BROWN 浅棕色-ZONE NATURAL 棕色-CREAM SODA (BROWN)淡紫-LILAC 紫色-PURPLE 浅紫色-DRY ROSE红色-RED 嫩粉色-LILY BLUSH 铁红色-RUST桔红色-CORAL HAZE 粉红-TAWNY BLUSH(PINK)中国红-MEDIUM RED (COUNTRY ~)浅粉红-PALE PINK KISS 桃红-JCP FUSHCIA 桔色-LILY ORANGE金色-PALE GOLD 银色-SILVER 骨色-TIMBER BORN(IVORY)茶色-TAWNEY 酒色-WINE 镍色-NICKEL深咖啡-AUTUMN MINK 咖啡色-GLOBAL BROWN 冰咖色-ICED COFFEE 黄色-SUNKING 深黄色-BUTTER CUP 浅黄色-YES YELLOW米黄色-POLOERE 黄褐色-CAMEL 05 驼色-CAMEL米色-BEIGE KISS 大米色-RICE 象牙色-IVORYKISS柠檬色-LAUREL 奶油色-BUTTER MILK 干草色-PALE HAY烟色-TAUPE SMOKE 原木色-SANDAL WOOD 卡其色-KAKI沙色-TOASTED ALMOND材料(MATERIAL)皮-LEATHER 软皮-CASTING LEATHER 反绒皮-SWEDE LEATHER猪皮-PIG SKIN 橡胶-RUBBER 塑料-PLASTIC注塑-INJECTION 纺织布-TEXTILE 打蜡皮-BURNISHED LEATHER帆布-CANVAS 弹力布-LYCRA 水牛皮-BUFFALO HIDE牛皮-COW LEATHER 纳帕PU-NAPA PU 拉米-LAMY合成革-SYNTHE PU牛巴-PU NUBOCK 网布-MESH整片底-UNIT SOLE EVA底-EVA SOLE 钉子-NAIL布类-FABRIC 麻布-JUTE 胶-GLUE/CEMENT皮克隆-PICALON 特丽可得-TRICOT 天皮-TOP LIFT/HELL LIFT打包带-PE TAPE包装(PACKAGE)塑料袋-POLY BAG 挂钩-HOOK 彩盒-COLOUR BOX字母扣-NYLON STRING 尺码标-SIZE LABEL 成分标-INGREDIENT LABEL 挂牌-HANGTAG 环保标-GREEN POINT 货号-MODEL配码-ASSORTMENT 布标-TEXTILE LABEL 商标-LOGO麦头-MARK 正麦-MAIN MARK 侧麦-SIDE MARK双-PAIR 双数-PAIRAGE 纸箱-CARTON箱-CASE 纸盒-BOX 纸板-CARDBOARD包装纸-TISSUE PAPER 干燥剂-SILICA GEL 价格标签-PRICE TICKET标签-TAG LABEL TICKET 胶带-TEPE 橡皮筋-ELASTIC BAND层-LAYER 长度-LENGTH 立方-CUBIC毛重-GROSS WEIGHT 净重-NET WEIGHT鞋类用具名称钳子-PINCER 布尺-TAPE 前帮机-TOE LASTING MACHINE剪刀-SCISSORS 输送带-CONVEROR 针车-STITCHING MACHINE毛刷-BRUSH 斩刀-CUTTING DIE 包装机-PACKING MACHINE铁捶-HAMMER 尺-RULER 后帮机-COUNTER LASTING M~空气枪-AIR GUN 鞋拔-SHOE HORN 裁断机-CUTTING MACHINE打钉机-NAILING M~ 模子-MOLD 压底机-SOLE PRESS MACHINE硬度计-HARDNESS TESTER 厚度计-THICKNESS TESTER 拉力机-TENSILE STRENGH TESTER温度计-MOISTURE TESTER制鞋过程裁断-CUTTING 针车-STITCHING 成型-LASTING攀鞋-WRAPPING 入前套-LAY TOE BOX 上糊-CEMENTING后帮-COUNTER LASTING 前帮-TOE LASTING 拔钉-PULL-OUT STAPLE 削皮-SKIVING 清洁CLEAN 贴底-SOLE LAYING修边-FOLDING 加热-HEATING 冷却-COOLING入楦-PUT-ON LAST 除楦-TAKE-OURT LAST 贴鞋垫-SOCK LAYING包装-PACKING 磨粗-BUFF 打蜡-WAXING定单应用定单号码-ORDER NO. 定单日期-DATE OF ORDER 交货日期-DELIVERY DATE工厂号码-FACTORY NO. 型体-STYLE 客户库存号码-CUST. STOCK NO.制造者-MFG 装船日期-SHIPPING DATE 客户定单号码-CUST. ORDER NO. 进货港口-PORT OF ENTRY鞋类缺点发霉-GET MILDEW 碎屑-CHIP 纸样错了-WRONG PATTERN太钝-TOO DULL 起毛-HAIRY 鞋面皱折-VAMP WRINKLE不配双-NOT IN PAIR 鞋面裂开-VAMP SPLIT OFF 线不平均-STITCHING NOT EVEN 鞋面掀开-VAMP OPEN UP 跟不正-HEEL NOT STRAIGHT 中底发角-ANGLE ON INSOLE裁断错误-WRONG CUTTING 贴底不正确-SOLE LAYING NOT PROPER鞋不平均-WRAPPING NOT EVEN 后带太高/低-BACKSTRAP TOOHIGH/LOW攀脱胶-CEMENT COMES OFF 大底不平-OUTSOLE NOT SMOOTH跟粘上胶-CEMENT ON HEEL 接着力不够-CEMENT NOT GOOD清洁度不够-CLEANESS NOT ENOUGH 鞋头陷下去-TOE BROKEN DOWN 钉子露出来-STAPLE COMESOFF 颜色不配合-COLOUR NOT MATCHINE 不照记号本-STITCHING NOT ON MARK贸易常识批发-WHOLE SALE 储藏-HOARD 成本价-COST PRICE内行-ADEPT 发票-INVOICE 大量生产-MASS PRODUCTION廉价-SALE 验货员-INSPECTOR 检验员-INSPECTION SHEET开发票-BILLING 征收-COLLECTION 航运公司-SHIPPING COMPANY产量-OUTPUT 倾销-DUMPING 装船文件-SHIPPING DOCUMENTS 仓库-WARE HOUSE 生意兴隆-BOOM 上等货-TOP QUALITY正牌货-STANDARD 破产-BANKRUPT 航空邮包-AIR PARCEL POST报价-OFFER 已装船-ON-BOARD 部分损失-PARTIAL LOSS收款人-PAYEE 流程-PROCESS 装船日期-SHIPPING DATE索赔-CLAIN 结关日-CLEAR DATE 装船通知-SHIPPING ADVICE佣金-COMMISSION 收货人-CONSIGNEE 交货期-DELIVERY DATE复查-DOUBLE CHECK 货柜-CONTAINER 装卸码头-SHIPPING DOCK出仓-DELIVERY FROM GODOWN 确认样品-COMFIRMATION SAMPLE (CFM SPL)小心轻放-HANDLE WITH CARE 即期信用证-SIGHT LETTER OF CREDIT试穿样品-FITTING SAMPLE(FITTING SPL)远期信用证-USANCE LETTER OF CREDIT可取消信用证-REVOCABLE LETTER OF CREDIT不可取消信用证-IRREVOCABLE LETTER OF CREDIT可转让信用证-ASSIGNABLE LETTER OF CREDIT不可转让信用证-U[此文档可自行编辑修改,如有侵权请告知删除,感谢您的支持,我们会努力把内容做得更好]。

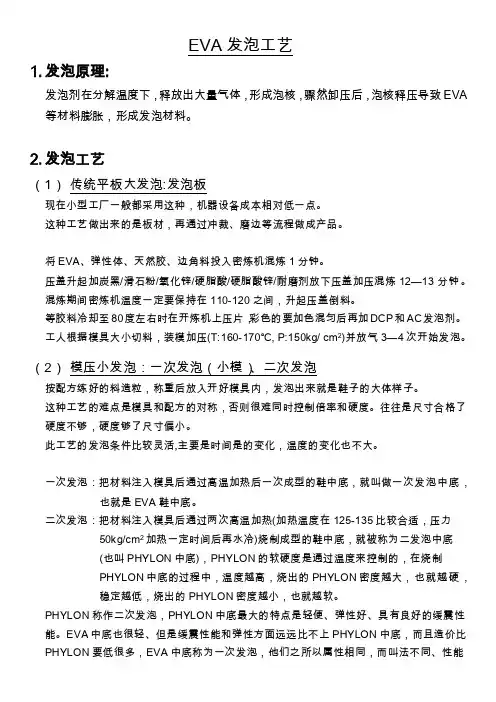

EVA发泡工艺1.发泡原理:发泡剂在分解温度下,释放出大量气体,形成泡核,骤然卸压后,泡核释压导致EVA 等材料膨胀,形成发泡材料。

2.发泡工艺(1)传统平板大发泡:发泡板现在小型工厂一般都采用这种,机器设备成本相对低一点。

这种工艺做出来的是板材,再通过冲裁、磨边等流程做成产品。

将EVA、弹性体、天然胶、边角料投入密炼机混炼1分钟。

压盖升起加炭黑/滑石粉/氧化锌/硬脂酸/硬脂酸锌/耐磨剂放下压盖加压混炼12—13分钟。

混炼期间密炼机温度一定要保持在110-120之间,升起压盖倒料。

等胶料冷却至80度左右时在开炼机上压片,彩色的要加色混匀后再加DCP和AC发泡剂。

工人根据模具大小切料,装模加压(T:160-170℃, P:150kg/ cm2)并放气3—4次开始发泡。

(2)模压小发泡:一次发泡(小模)、二次发泡按配方练好的料造粒,称重后放入开好模具内,发泡出来就是鞋子的大体样子。

这种工艺的难点是模具和配方的对称,否则很难同时控制倍率和硬度。

往往是尺寸合格了硬度不够,硬度够了尺寸偏小。

此工艺的发泡条件比较灵活,主要是时间是的变化,温度的变化也不大。

一次发泡:把材料注入模具后通过高温加热后一次成型的鞋中底,就叫做一次发泡中底,也就是EVA鞋中底。

二次发泡:把材料注入模具后通过两次高温加热(加热温度在125-135比较合适,压力50kg/cm2加热一定时间后再水冷)烧制成型的鞋中底,就被称为二发泡中底(也叫PHYLON中底),PHYLON的软硬度是通过温度来控制的,在烧制PHYLON中底的过程中,温度越高,烧出的PHYLON密度越大,也就越硬,稳定越低,烧出的PHYLON密度越小,也就越软。

PHYLON称作二次发泡,PHYLON中底最大的特点是轻便、弹性好、具有良好的缓震性能。

EVA中底也很轻、但是缓震性能和弹性方面远远比不上PHYLON中底,而且造价比PHYLON要低很多,EVA中底称为一次发泡,他们之所以属性相同,而叫法不同、性能不同,原因在于PHYLON是二次发泡,而EVA则是一次发泡。

Adidas、nike、李宁鞋子的专利技术AdidasTORSION SYSTEM -扭转系统(大底技术)TORSION SYSTEM重现了赤脚的概念,使脚能够扭转自如.其交叉的热塑扭转系统使脚弓得到支持,从而更好的控制运动,避免可能出现的伤害。

其形状有“X“型、“Y“型和“V“型等。

近来更发明了三维扭转系统和延伸扭转系统。

adiPRENE -(中底技术)由注射EVA制成,重量比普通EVA轻20%,而且更耐用!小蜂巢式的结构使其具有理想的弹性避震功能。

可作为垫片设置在关键着力点。

其按功能分为两类:吸收冲击功能、反弹功能。

adiWARE -(大底技术)是由高耐久性材料参照剧烈摩擦试验而制造的,为一种高耐磨的橡胶。

ADIDAS对采用adiWARE技术为外底材料的鞋子提供六个月的质量保证。

adiDRY一种防水的PU防护层。

所有护层内衬接缝处都有防水封带。

这种护层使脚在任何户外气候条件下,保持干爽舒适,使鞋更透气。

adiTUFF是一种耐磨的特殊材料,常用于鞋面脚趾处。

这种材料的加入,可防止鞋面过早磨损,从而延长寿命。

其高耐磨性经过材料实验室的检测证明。

TRAXION -奇钉技术据人体工程学原理,经过测试制成的特殊大底。

它比一般外底更具抓地性,具有防滑功能,因而特别适合于野外跑步鞋。

adiFIT适应于婴儿鞋,其鞋垫抽出后可见上面的标记。

如果婴儿的脚在网线范围内,说明该鞋合脚。

PREDATOR -猎鹰技术适用于足球鞋,在鞋面及鞋带处设置有橡胶鳍,使射球时球与鞋的接触面增强。

Coolmax -服装技术coolmax是杜邦公司众多纤维和布料的一种。

它由四重排汉道纤维制成,当身体流汗时,其独特的纤维能将湿气导引至布料表层,并迅速蒸发不会保持湿气,所以它不会附着在皮肤上,不会有粘腻的感觉。

LYCRA POWERLYCRA是杜邦公司生产的名牌氨沦丝,具有卓越的延伸及恢复性能。

让服装成为人体的第二层皮肤,对皮肤形成必要的压力,使肌肉运动处于最佳的状态,并带来最大舒适。

FLEXIPADEasier Maintenance, Higher Robustness & Reliability and Better Performance &Compactness thanks to a unique patented pads design and superior PEEK material properties.PEEK shell easily dismountable &replaceableHIGH PERFORMANCE THRUST & GUIDE BEARING PADSADVANCED BEARING TECHNOLOGY•GE Vernova’s Flexipad thrust & guide bearing pads have a sliding surface with a long lasting and high-performance thermoplastic coating.•They advantageously replace conventional babbitt pads, thanks to higher resistance to temperature and pressure, higher dimensional integrity and a lower friction co-efficient.•GE Vernova can upgrade existing babbitt pads to Flexipad by remachining the pads and installing a Flexipad PEEK shell instead of the babbitt coating.Pad repair in less than 1 hour on site Reduction of spare parts inventory: Only thin PEEK shells to be kept as spares5x less wear than PTFE coatings (*)Safe operation without injectionUp to 30% reduction in bearing losses(*) wear measured on our test rig by operating PEEK and PTFE pads in similar conditionsFLEXIPAD BENEFITSEasily & quickly repairable on site:in case of coating damage, one only has to dismount the pad from the bearing, dismount the Flexipad PEEK shell and install a spare one and remount the pad. The pad repair can be done on site in less than 1 hour. There is no need anymore to ship the pads to an external supplier for rebabbittingMore robust & reliable bearings: due to the low thermal conductivity of the Flexipad coating, the bearing pads have smaller thermal deformations compared to conventional materials, allowing a fast unit re-start after a stop. Low friction properties keep units with ageing hydraulic jacking systems operational, despite more starts and stops.More compact, more efficient bearings: with higher thermal and mechanical strengths, new bearings can be downsized and work with significantly higher loads.Reduced upgrade cost: Flexipad’shigh load carrying properties allow to keep existing thrust bearing arrangements and civil works, thus reducing upgrade costs if unit power and weight are increased.Improved peace of mind by solvinghot or problem bearings : Flexipad is more resistant to temperature and pressure, meaning it is less likely to seize up or trip a machine.HIGH PERFORMANCE THRUST & GUIDE BEARING PADSFEATURESFlexipad has a composite coating made from PEEK which improves pad characteristics. The coating is easily dismountable –see picture on the first page –with no need for any specific tooling.GE Vernova recommends the use of Flexipad pads for all Guide & Thrust bearings in vertical and horizontal arrangements. In particular Flexipad is particularly suited •To solve bearing issues such as overheating of the bearing: as it allows for higher specific pressure and reduced oil temperature increase•In refurbishment in case of increase of rotation speed or thrust load•For new bearings to reduce friction lossesFLEXIPADCONTACT US************************+ 1855 522 0755PEEK COATING SUPERIOR CHARACTERISTICS•High temperature resistance and maintenance of characteristics at higher temperatures •Tough material with lowdeformation, low wear and creep for a longer life-time•Very high load carrying capacity •Low friction co-efficient improves sliding propertiesMain CharacteristicsPEEK*Babbitt**PTFE***Melting point (°C)341240327Tensile strength room temp. (MPa)24022Tensile strength at 100°C. (MPa)15015Seizure, max. load (MPa)≥25 3.5w orking pressure 14Friction coefficient in oil0.0510.20.043Wear (based on comparative wear test)~2µm ~11µm Elongation2%300%Hardness (Rockwell)12620* PolyEtherEtherKetone ** or ‘White Metal’ *** PolyTetraFluoroEthylene, or Teflon®FEEDBACK FROM THE FIELD20 years experience with PEEK coated pads. Flexipad itself was first installed on a hydro unit in 2018. 14 thrust bearings & 3 guide bearings have been equipped worldwide with Flexipad pads for units from 4 MW to 188 MW, 75 rpm to 600 RPM. Examples:•Thrust bearing failure on Swiss unit in 2017. Due to low-speed rotation of the rotor for several hours after a guide vane failure. The mechanism got locked and was not able to close completely due to debris that entered between the blades. GE Vernova a solution based on PEEK material. •Test simulated bearing seizure due to lack of lubricating oil. In this scenario during operation with 4 MPa and 800 rpm the oil was removed from thebearing housing. The bearing continued to operate for 15 minutes. The surface was only slightly worn without any catastrophic damage visible.。

鞋类英文专用术语一、鞋子种类(shoes variety)Athletic /Sports shoes运动鞋Casual shoes便鞋Hiking shoes(登山鞋)/Travelling shoes旅游鞋Slipper拖鞋Sandals凉鞋Boots马靴Work boots工作鞋Axido沙滩鞋Canvas帆布鞋Sport boots运动鞋Pumps(轻舞鞋)高跟鞋Climbing shoes登山鞋Football shoes足球鞋Jogging shoes慢跑鞋Basketball shoes篮球鞋Casualshoes便鞋Leisure休闲鞋Tennis shoes网球鞋Baseball shoes棒球鞋Aerobic shoes舞蹈鞋二.部位名称(Location name) upper vamp鞋面,帮面counter后套binding滚边last 楦头top line鞋口sole edge底边seams缝合处bows 饰片Ornament饰物Overlay饰片stain染色adhered粘贴bumper包头片?steel toe钢头eyelet and lace鞋眼带embroidery 电绣quarter鞋腰(身)Tongue鞋舌Insole中底Welt 沿条Siping切沟Soles底台Zigzag万能?Eye stay眼套Collar领口Top 面线Back strap后吊带(织带)Outsole大底Mid sole-EVA EVA中插Open toe鞋头开口Open back鞋后开口Lace loop穿环Reinforcements补强Hand sews手缝马克Reinforce tape补强带Inside corners内弯角Insole board中底纸板Textile lining布料衬里Plat forms包边中底台Wovens/weaves编织类Lining内里Heel 脚跟Foxing护条Eyelet 鞋眼片Socks鞋垫Box toe鞋衬里Toe box 套头Print印刷Perforation冲孔Toe cap鞋头Toe part鞋头部Bobbin底线Bar加强线Heat sealed熔封鞋的一搬缺点Defect) Vamp wrinking鞋面皱纹Stitching not even车不平均Tricot shows up特丽可得露出来Wrapping not even攀帮不均匀Shank too loose铁心太松Heel not straight后套不正Sole come off底脱胶Wrong pattern 纸板错误Wrong material材料错误Wrong cutting裁断错误Toe broken down鞋头凹陷Color variation色差Color not matching色差Wrong last 楦头错误Wrong colour颜色错误Damaged upper鞋面破损Not in pair不配双Crooked back stay 后套歪斜Crooked upper鞋面弯曲Crooked屈曲,不平顺Vamp length鞋头大小Lasting off center攀歪Sole laying not proper(centered)贴底不正确Back strap too high(low,long,short)后拉带太高/低/长/短Abrasion磨损Stitching not on the mark不照记号齿车Angle on insole中底发角Vamp open up鞋面掀开Wrapping not tight攀帮不紧Shank not straight铁心不正Cementing comes off脱胶Outsole not smooth大底不平Gore too weak松紧带弹性不佳Cement on heel鞋跟沾胶Cementing no good接着力不佳Cleanness not enough清洁度不佳Vamp split off 鞋面爆开Loose thread脱线Broken thread断线Turn yellow变黄Turn dark变黑Pinch in 缩进去Flatten变平Rough粗糙x-ray透痕smeary污染hairy 起毛gaping 缝隙sole adhesion大底欠胶?chip碎屑dirty 脏的get mildew发霉back height 后跟高度over cemented溢胶bottom dirty大底不洁鞋用英文皮革介绍也是可以当词典用的. 皮革材料汇总皮料制造流程wet operation 湿场作业trimming and sorting 削整及分皮soaking 浸水fleshing 削肉unhairing 脱毛bating 酵解软化picking 浸酸?tanning 鞣制wringing 挤水splitting and shaving 起层及削里retanning, coloring 再鞣,染色setting out 张皮dry operation 干场作业drying 干燥conditioning 回湿?staking 铲软 skiving 削皮,铲皮buffing 磨皮finishing 整饰measuring 量皮grading 分级aalligator 鳄鱼皮也称crocodile皮antelope leather 羚羊皮革bbuckskin 鹿绒皮buffalo hides 水牛皮buffalo hides, salted, wet 盐湿水牛皮bull hide 公牛皮butt-branded steers 臀部有烙印阉牛皮butt leather 臀皮ccabreta 卡利大皮?calf leather 小牛皮calfskin 小牛皮calfskin, with the hair on, dyed 染色小牛皮camel leather 骆驼皮革cape skin 开普皮carpincho 河马皮cattle hide 大牛皮cattle leather, dyed 染色牛皮cattle leather, metallized 烫金属牛皮cattle leather, patent 漆牛皮chamois-dressed leather 油鞣皮(雪米皮)chicago wet-salted hides 芝加哥湿盐皮colorado steerhide 科罗拉多阉牛皮cordovan 马臀皮covers, file leather 公文夹用皮革cowhide 母牛皮cowhides, salted, wet 盐湿黄牛皮crocodile leather 鳄鱼皮ddeer leather 鹿皮革deerskin 鹿皮deerskin, chamois-dressed 鹿皮doeskin 羊绒皮doeskin, chamois-dressed 油鞣牡鹿皮dried 皮干fflesher 羊榔皮fox fur skin, dressed 硝制狐皮fox fur skin, dyed 染色狐皮fur skins, tanned or dressed 鞣制或硝制毛皮goat leather 山羊皮goat leather, dyed 染色山羊皮goat leather, metallized 烫金属山羊皮goatskin 山羊皮goatskin, dyed 染色山羊皮hhairsheep 直毛羊皮---绵羊的毛呈直条波浪型头发一样heavy cows 重量母牛皮heavy native cows 重量无烙印母牛皮heavy native heifers 重量无烙印小母牛皮heavy native steers 重量无烙印阎牛皮heifer 母童牛皮hide 大件皮hide, buffalo, dehaired, tanned 水牛皮hide, cattle or cow, dehaired, tanned 牛皮(黄牛皮) hide, ox, dehaired, tanned 牡牛皮hide, steer, dehaired, tanned牡犊皮hide, zebra, dehaired, tanned班玛皮holster, pistol, leather 手枪皮套horsehide 马皮horse leather, dyed 烫金属马皮horse leather, patent 漆马皮inner hide, cow and buffalo dried 黄牛, 水牛内皮kangaroo 袋鼠皮kidskin skin 小羊皮lambskin, chamois-dressed 油鞣仔羊皮leather of sheep and lamb skins 绵羊及仔绵羊皮leather auxiliaries 皮革助剂leather of goat and kidskins 山羊及仔山羊皮leather sole 皮底leather upper 皮面leather, buffalo 水牛革leather, calf, chrome-tanned colored and polished 铬鞣染色打光小牛皮leather, cattle or cow 牛革leather, crust, calf 硬小牛皮leather, curried, calf 鞣制小牛皮leather, kid skin 仔山羊皮leather, ox 牡牛革leather, sole, calf 制鞋底用小牛皮leather, vamp, calf 制鞋面小牛皮leather, horse or equine 马革leather, mule 骡革leather, steer 牡犊革leather, zebra 斑马革leopard fur skin, dressed 硝制豹皮leopard fur skin, dyed 染色豹皮light cows 轻量母牛皮light native cows 轻量无烙印母牛/阉牛皮lizard leather 蜥蜴皮lizard skin 蜥蜴皮=蜥蜴类动物的皮marten fur skin, dressed 硝制貂皮marten fur skin, dyed 染色貂皮macha 摩卡皮muntafac fur skin, dressed硝制羌皮muntafac fur skin, dyed 染色羌皮ostrich 鸵鸟皮parchment-dressed leather 羊皮纸型熟皮patent and metallized leather 漆皮及硬化剂peccary 野猪皮pelt 生毛皮pheasant 鳗鱼皮pickled hides 浸酸牛皮pickled lamb pelts, run 浸酸羔羊皮pigskin lining leather 猪里皮pigskin upper leather 猪面皮pigskin split leather 猪榔皮pigskin 原料盐皮pigskin nubuck upper leather 猪磨面皮pigskins leather, tanned 加工猪皮pony skin 小马皮pony skin, dyed 染色小马皮queensland hides 昆士兰皮reconstituted and artificial leather containing leather or leather fibre 再生&人造皮革release paper 离型纸shark leather 鲨鱼皮sharkskin 鲨鱼皮shearling 毛羊皮sheep and lambskins with the wool 带毛之绵羊及其羔羊皮sheep and lambskins without the wool 不带毛之绵羊及其羔羊皮sheep leather 绵羊皮sheep leather, dyed 染色绵羊皮sheep leather, metallized 烫金属绵羊皮sheep leather, patent 漆绵羊皮sheepskin 硝制绵羊皮sheepskin, chamois-dressed 油鞣羊皮sheepskin. with hair on, dyed 染色绵羊皮skin 小件皮skin, bird, with feathers removed, ranned 去毛加工之鸟皮skin, rhinceros 犀牛皮skiver 薄羊面皮snakeskins, dried 干蛇皮snakeskins, tanned 加工蛇皮split leather 榔皮, 二层皮steerhide 阉牛皮suede 反毛皮swine leather, dyed 染色猪皮swine leather, enamelled 上釉猪皮swine leather, metallized 烫金猪皮tanning auxiliaries 鞣革助剂tanning extracts 鞣革剂tassels, leather 皮革饰缝tiger fur skin, dressed 硝制虎皮titanium 钛白粉trimmings, leather 皮制饰品皮upper leather of cattle and calf 牛及小牛之面皮upper leather of goat 山羊面皮upper leather of kid 仔山羊二.部位名称(compnent name)upper/ vamp鞋面,帮面back counter后套binding包边piping 滚边last 楦头topline鞋口sole edge底边角seams车线bow 蝴蝶结Ornament饰物Overlay上片stain染色adhere粘贴bumper??包头片??steel toe钢头eyelet and lace鞋眼鞋带embroidery 电绣quarter鞋腰(身)Tongue鞋舌Insole中底Welt 沿条Siping切沟??大底挖槽outsole groove Soles底台Zigzag万能车Eye stay鸡眼套Collar领口(靴子的)Top 可指鞋面,一般用upperBack strap后跟条Outsole大底Mid sole-EVA EVA中底Open toe 鱼嘴鞋,露趾鞋Open back后空式鞋,无后包的Lace loop鞋带穿环Reinforcements补强Hand sews手缝马克or handstitching Reinforce tape补强带Inside corners内弯角Insole board中底板Textile lining布料衬里Platform 水台Wovens/weaves编织类Lining内里Heel 鞋跟Foxing护条or velt or randEyelet 鞋眼or 鸡眼Socks鞋垫鞋衬里liningPrint印刷Perforation冲孔or punchingToe cap鞋头鞋头部toe cap底线outsoel stitching。

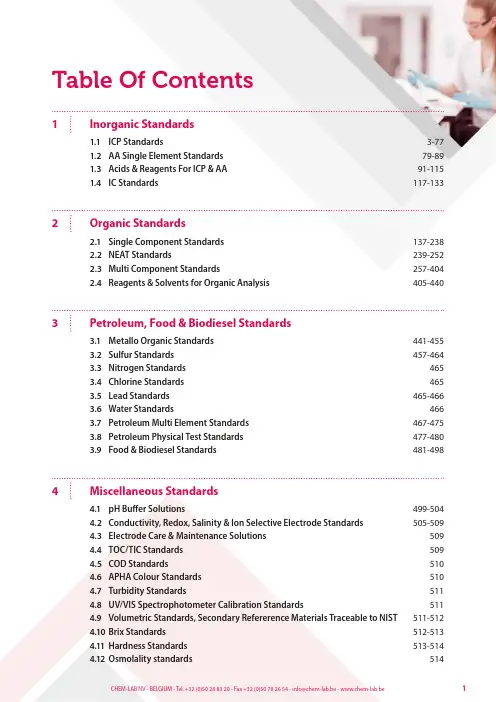

3-772CHEM-LABNV-BELGIUM-Tel.+32(0)50288320-Fax+32(0)*****************************.chem-lab.be4CHEM-LABNV-BELGIUM-Tel.+32(0)50288320-Fax+32(0)*****************************.chem-lab.beICP Single Element Standards 10 000 mg/LI C P S TA N D A R D S 10.000 P P MElement HNO 3HCl H 2ONH 4OHHFHNO 3/HF HNO 3/tart.KOHNaOHOthersAl CL01.0103CL01.0104Sb CL01.0123CL01.0124As CL01.0134Ba CL01.0203CL01.0204Be CL01.0214Bi CL01.0223B CL01.0233Cd CL01.0303Ca CL01.0314Ce CL01.0323Cs CL01.0333Cr CL01.0364CL01.0363Co CL01.1123CL01.1128Cu CL01.1133CL01.1134Dy CL01.0433Er CL01.0503Eu CL01.0513Gd CL01.0703Ga CL01.0713Ge CL01.0743Au CL01.0733Hf CL01.0804CL01.0803Ho CL01.0823In CL01.0923Ir CL01.0933Fe CL01.0903CL01.0904La CL01.1203Pb CL01.1223Li CL01.1214Lu CL01.1233Mg CL01.1304CL01.1310Mn CL01.1313Hg CL01.1153Mo CL01.1334CL01.1333Nd CL01.1413Ni CL01.1423Nb CL01.1433Pd CL01.1603P CL01.0643CL01.0633CL01.0634Pt CL01.1613K CL01.1104Pr CL01.1623Re CL01.1804CL01.1803Rh CL01.1813Rb CL01.1824Ru CL01.1834Sm CL01.1903Sc CL01.1913Se CL01.1923Si CL01.1943CL01.1934CL01.1933Ag CL01.2603Na CL01.1404Sr CL01.1963S CL01.2644CL01.2643Ta CL01.2003CL01.2004Te CL01.2015CL01.2014Tb CL01.2023Tl CL01.2033Th CL01.2043Tm CL01.2053Sn CL01.2063Ti CL01.2073CL01.2074W CL01.2303CL01.2304CL01.2333V CL01.2203Yb CL01.2503Y CL01.2513Zn CL01.2613ZrCL01.2633I C P S T A N D A R D SCHEM-LAB NV - BELGIUM - Tel. +32 (0)50 28 83 20 - Fax +32 (0)50 78 26 54 - info@chem-lab.be - www.chem-lab.be6AntimonyArsenicumBariumBerylliumBismuthBoronCadmiumCalciumCalcium oxideCeriumCesiumI C P S I N G L E E L E M E N T S CHEM-LABNV-BELGIUM-Tel.+32(0)50288320-Fax+32(0)*****************************.chem-lab.be7CobaltCopperDysprosiumErbiumEuropiumGadoliniumGalliumGermaniumGoldHafniumHolmium8CHEM-LABNV-BELGIUM-Tel.+32(0)50288320-Fax+32(0)*****************************.chem-lab.beIridiumIronLanthanumLeadLithiumLutetiumMagnesiumNEWMagnesium oxideManganeseMercuryMolybdenumNeodymiumI C P S I N G L E E L E M E N T S CHEM-LABNV-BELGIUM-Tel.+32(0)50288320-Fax+32(0)*****************************.chem-lab.be9NiobiumPalladiumPhosphorusPhosphorus pentoxidePlatinumPotassiumPotassium oxidePraseodymiumRheniumRhodiumRubidiumCHEM-LABNV-BELGIUM-Tel.+32(0)50288320-Fax+32(0)*****************************.chem-lab.be10SamariumScandiumSeleniumSiliciumSilverSodiumSodium oxideStrontiumSulfurTantalumTelluriumI C P S I N G L E E L E M E N T S CHEM-LABNV-BELGIUM-Tel.+32(0)50288320-Fax+32(0)*****************************.chem-lab.be11ThalliumThoriumThuliumTinTitaniumTungstenVanadiumYtterbiumYttriumZincZirconiumCHEM-LABNV-BELGIUM-Tel.+32(0)50288320-Fax+32(0)*****************************.chem-lab.be12A Certificate of Analysis is provided with each ICP standard stating:- Actual certified concentration of the final solution- Traceability to NIST- Expiration date- Trace impurities detected I C P S I NCHEM-LABNV-BELGIUM-Tel.+32(0)50288320-Fax+32(0)*****************************.chem-lab.be13ICP Single Element Standards 1 000 mg/LI C P S TA N D A R D S 1.000 P P MElement HNO 3HCl H 2ONH 4OHHFHNO 3/HF HNO 3/tart.KOH NaOHOthersAl CL01.0101CL01.0102Sb CL01.0121CL01.0122CL01.0162As CL01.0133CL01.0132CL01.0131Ba CL01.0201CL01.0202Be CL01.0212CL01.0211Bi CL01.0221B CL01.0232CL01.0231Cd CL01.0301Ca CL01.0311CL01.0312Ce CL01.0321Cs CL01.0331Cr CL01.0362CL01.0361CL01.0352Co CL01.1121CL01.1122Cu CL01.1131CL01.1132Dy CL01.0431Er CL01.0501Eu CL01.0511Gd CL01.0701Ga CL01.0711Ge CL01.0741CL01.0721Au CL01.0731Hf CL01.0802CL01.0801Ho CL01.0821In CL01.0921Ir CL01.0931Fe CL01.0901CL01.0902La CL01.1201CL01.1202Pb CL01.1221Li CL01.1212CL01.1211Lu CL01.1231Mg CL01.1301CL01.1302Mn CL01.1311CL01.1312Hg CL01.1151Mo CL01.1332CL01.1331Nd CL01.1411Ni CL01.1421CL01.1422Nb CL01.1431Os CL01.1501Pd CL01.1601P CL01.0641CL01.0631Pt CL01.1611K CL01.1101CL01.1102Pr CL01.1621Re CL01.1802CL01.1801Rh CL01.1811Rb CL01.1822CL01.1821Ru CL01.1831Sm CL01.1901Sc CL01.1911Se CL01.1922CL01.1921Si CL01.1999CL01.1945CL01.1932CL01.1931CL01.1935Ag CL01.2601Na CL01.1401CL01.1402Sr CL01.1962CL01.1961S CL01.2641CL01.2642Ta CL01.2001CL01.2002Te CL01.2012CL01.2013CL01.2011Tb CL01.2022Tl Th CL01.2041Tm CL01.2051Sn CL01.2061CL01.2062Ti CL01.2072CL01.4601CL01.2071CL01.2075W CL01.2302CL01.2301CL01.2331V CL01.2201Yb CL01.2501Y CL01.2511Zn CL01.2611CL01.2612ZrCL01.2632CL01.2631CL01.2672I C P S I N G L E E L E M E N T S T A N D A R D SCHEM-LAB NV - BELGIUM - Tel. +32 (0)50 28 83 20 - Fax +32 (0)50 78 26 54 - info@chem-lab.be - www.chem-lab.be14Aluminium(III) oxideAntimonyArsenicumBariumBerylliumBismuthBoronCadmiumI C P S I N G L E E L E M E N T S CHEM-LABNV-BELGIUM-Tel.+32(0)50288320-Fax+32(0)*****************************.chem-lab.be15Calcium oxideCeriumCesiumChromiumCobaltCopperDysprosiumErbiumEuropiumGadoliniumGalliumCHEM-LABNV-BELGIUM-Tel.+32(0)50288320-Fax+32(0)*****************************.chem-lab.be16GoldHafniumHolmiumIndiumIridiumIronIron(III) oxideLanthanumLeadLithiumLutetiumI C P S I N G L E E L E M E N T S CHEM-LABNV-BELGIUM-Tel.+32(0)50288320-Fax+32(0)*****************************.chem-lab.be17Magnesium oxideManganeseManganese(III) oxideMercuryMolybdenumNeodymiumNickelNiobiumOsmiumPalladiumDon’t see the exact solution you need?E-mail us the Tailor Made Standard Quotation request form in the back of the catalog. 18CHEM-LABNV-BELGIUM-Tel.+32(0)50288320-Fax+32(0)*****************************.chem-lab.bePhosphorus pentoxidePlatinumPotassiumPotassium oxidePraseodymiumRheniumRhodiumRubidiumRutheniumSamariumScandiumI C P S I N G L E E L E M E N T S CHEM-LABNV-BELGIUM-Tel.+32(0)50288320-Fax+32(0)*****************************.chem-lab.be19SiliciumSilicium dioxideSilverSodiumSodium oxideStrontiumSulfurTantalumCHEM-LABNV-BELGIUM-Tel.+32(0)50288320-Fax+32(0)*****************************.chem-lab.be20TerbiumThalliumThoriumThuliumTinTitaniumTungstenVanadiumYtterbiumI C P S I N G L E E L E M E N T SZincZirconiumLuis BianchiISO/IEC 17025:2005 - General requirements for the competence of calibration laboratories ISO 9001:2008 - Quality ManagementISO Guide 34:2009 - General requirements for the competence of reference material producers A Certificate of Analysis is provided with each ICP standard stating:- Actual certified concentration of the final solution - Traceability to NISTAntimonyArsenicumBariumBerylliumBoronCadmiumCalciumCeriumCesiumChromiumCobaltCopperDysprosiumErbiumI C P S I N G L E E L E M E N T SGadoliniumGalliumGermaniumGoldHafniumHolmiumIndiumIridiumIronLanthanumLeadLithiumLutetiumManganeseMercuryMolybdenumNeodymiumNickelNiobiumOsmiumPalladiumPhosphorusPlatinumPotassiumPraseodymiumRheniumRhodiumI C P S I N G L E E L E M E N T SRutheniumSamariumScandiumSeleniumSiliciumSilverSodiumSulfurTantalumTelluriumTerbiumThalliumThoriumThuliumTinTitaniumTungstenVanadiumYtterbiumYttriumZincZirconium NEWDon’t see the exact solution you need?I C P S I N G L E E L E M E N T SAluminiumAntimonyBariumBerylliumBismuthBoronCadmiumCalciumCeriumCesiumChromiumCobaltCopperDysprosiumEuropiumGadoliniumGalliumGermaniumGoldHafniumHolmiumIndiumIridiumIronLanthanumLeadI C P S I N G L E E L E M E N T SLutetiumMagnesiumManganeseMercury NEWMolybdenumNeodymiumNickelNiobiumOsmiumPalladiumPhosphorusPlatinumPotassiumPraseodymiumRhodiumRubidiumRutheniumSamariumScandiumSeleniumSiliciumSilverSodiumSulfurTantalumTelluriumTerbiumThalliumI C P S I N G L E E L E M E N T SThuliumTinTitaniumTungstenVanadiumYtterbiumYttriumZincZirconium NEWChem-Lab’s certified “Custom Made Standards” will save you time and money.Multi Element ICP QC Standard sol. (QCS-23) (23E)CL01.13610Multi Element ICP QC Standard sol. (QCS-01) (23E)CL01.13601I C P M U L T I E L E MMulti Element ICP QC Standard sol. (QCS-04) (19E)NEW CL01.13604Multi Element ICP QC Standard sol. (QCS-19) (19E)CL01.13608Multi Element ICP QC Standard sol. (QCS-02) (7E)CL01.13602Multi Element ICP ASL QC Standard sol. (QCS-ASL-7) (7E)CL01.13607Multi Element ICP QC Standard sol. (QCS-06) (4E)CL01.13606I C P M U L T I E L E MA Certificate of Analysis is provided with each ICP standard stating:- Actual certified concentration of the final solution- Traceability to NIST- Expiration date- Trace impurities detectedMulti Element ICP SQS Standard sol. (SQS-01) (33E)CL01.13631I C P M U L T I E L E MReference Materials - Contents of certificates and labelsGeneral requirements for the competence of calibration laboratoriesPage 2 of 2Chem-Lab multi-element standards are compared against the following NIST SRMs Element Aq. SRMOil SRMElement Aq. SRMOil SRMAg 31511077a Nb 3137-Al 3101a 1075a Nd 3135a -As 3103a 3103a Ni 31361065b Au 3121-NO3-3185-B 31073107NO2-136e -Ba 3104a 1051b P 3139a 1071b Be 3105a 3105a Pb 31281059c Bi 31063106Pd 3138-Br-3184-PO4-33186-Ca 3109a 3109Pr 3142a -Cd 31081053a Pt 3140-Ce 3110-Rb 3145a -Cl-919b -Re 3143-Co 31133113Rh 3144-Cr 3112a 1078b S 31543154Cs 3111a -Sb 3102a 3102a Cu 31141080a Sc 3148a 3148a Dy 3115a -Se 31493149Er 3116a -Si 31501066a Eu 3117a -Sm 3147a -F-3183-Sn 3161a 1057b Fe 3126a 1079b SO4-23181-Ga 3119a -Sr 3153a 1070a Gd 3118a -Ta 3155-Ge 3120a -Tb 3157a -Hf 3122-Te 3156-Hg 31333133Th 3159-Ho 3123a -Ti 3162a 3162a In 3124a -Tl 31583158K 3141a 3141a Tm 3160a -La 3127a 3127a U 3164-Li 3129a 1060a V 31651052b Lu 3130a -W 3163-Mg 3131a 3131a Y 3167a 3167a Mn 31323132Tb 3166a -Mo 31343134Zn 3168a 1073b Na3152a1069bZr31693169*ICP-EPA Methods (Method 200.7 Version 3.3 & earlier) - Laboratory Performance Check Standard (LPCS) Contains 29 elements in 5% HNO3Multi Element ICP LFSS Standard sol. LFSS-01 (25E)CL01.13772*ICP-EPA Methods (Method 200.7 Version 3.3 & earlier) - Laboratory Fortifying Stock Solution (LFSS) Contains 25 elements in 5% HNO3 + traces HFMulti Element ICP SP Standard sol. SP-03 (12E)CL01.13743I C P M U L T I E L E*ICP-EPA Methods (Methods 6010A - 6010B - 200.7 Version 3.3 and earlier) - Mixed Calibration Standard 1 Contains 6 elements in 2% HNO3 (MCS-Multi Element ICP CAL Standard sol. MCS-04 (6E)CL01.13734Multi Element ICP SP Standard sol. SP-05 (5E)CL01.13745Multi Element ICP CAL Standard sol. MCS-02 (5E)CL01.13732 *ICP-EPA Methods (Methods 6010A - 6010B - 200.7 Version 3.3 and earlier) - Mixed Calibration Standard 2 Contains 5 elements in 2% HNO3 (MCS-Multi Element ICP SP Standard sol. SP-05R (5E)CL01.13754*ICP-EPA Methods (Method 200.7 Version 3.3 and earlier) - Spiking Standard for Drinking Water # 5R Contains 5 elements in 5% HNO3 (M-200.7-SP-Multi Element ICP SIC Standard sol. SICS-02 (5E)CL01.13762Multi Element ICP PLASOL Standard sol. M-200.7-PLASOL-1 (4E)CL01.13723*ICP-EPA Methods (Method 200.7 Version 4.4, May 1994) - Plasma Solution (PLASOL) - Determining optimum viewing height of the plasma analytical zone.I C P M U L T I E L E MMulti Element ICP SP Standard sol. SP-01R (4E)CL01.13751 *ICP-EPA Methods (Method 200.7 Version 3.3 and earlier) - Spiking Standard for Drinking Water # 1R Contains 4 elements in H2O + traces HF (M-Multi Element ICP SP Standard sol. SP-02R (4E)CL01.13752 *ICP-EPA Methods (Method 200.7 Version 3.3 and earlier) - Spiking Standard for Drinking Water # 2R Contains 4 elements in 2% HNO3 (M-200.7-SP-Multi Element ICP CAL Standard sol. MCS-03 (3E)CL01.13733Tailor Made Mixtures can be formulated to meet your special applications.Multi Element ICP SP Standard sol. SP-01 (3E)CL01.13741Multi Element ICP TUNSOL Standard sol. M-200.7-TUNSOL-1 (2E)CL01.13724*ICP-EPA Methods (Method 200.7 Version 4.4, May 1994) - Tuning Solution (TUNSOL) - Adjusting the aerosol argon gas flow prior to calibration and analysis.Mono Element ICP SP Standard sol. TCLP-02 (1E)CL01.13773*ICP-EPA Methods (Methods 6010B - 200.7 Version 3.3 and earlier) - Spiking & Mercury Standard - TCLP Standaard 2 Contains 1 elements in 5%I C P M U L T I E L E MMono Element ICP SP Standard sol. SP-04R (1E)CL01.13753 *ICP-EPA Methods (Method 200.7 Version 3.3 and earlier) - Spiking Standard for Drinking Water # 4R Contains 1 elements in 2% HNO3 (M-200.7-SP-Mono Element ICP SIC Standard sol. SICS-01 (1E)CL01.13761Mono Element ICP SP Standard sol. TCLP-02-10X (1E)CL01.13746*ICP-EPA Methods (Method 200.7 Version 4.4, May 1994) - Instrument Fortifying (Spiking) Standard # 1 Contains 26 elements in 5% HNO3 + tracesMulti Element ICP IPC Standard sol. M-200.7-IPC-01 (26E)CL01.13721 *ICP-EPA Methods (Method 200.7 Version 4.4, May 1994) - Instrument Performance Check (IPC) Contains 26 elements in 5% HNO3 (M-200.7-IPC-I C P M U L T I E L E*ICP-EPA Methods (Method 200.7 Version 4.4, May 1994) - Instrument Fortifying (Spiking) Standard for Solids # 1 Contains 24 elements in 5% HNO3Multi Element ICP LFSS Standard sol. M-200.7-LFSS-01W (22E)CL01.13712 *ICP-EPA Methods (Method 200.7 Version 4.4, May 1994) - Instrument Fortifying (Spiking) Standard for Water # 1 Contains 22 elements in 5% HNO3Multi Element ICP CAL Standard sol. M-200.7-01 (10E)CL01.13701Chem-Lab’s certified “Custom Made Standards” will save you time and money.Multi Element ICP CAL Standard sol. M-200.7-02R (6E)CL01.13702Multi Element ICP LFSS Standard sol. M-200.7-LFSS-02 (5E)CL01.13714*ICP-EPA Methods (Method 200.7 Version 4.4, May 1994) - Instrument Fortifying (Spiking) Standard # 2 Contains 5 elements in 5% HNO3 + traces HFMulti Element ICP IPC Standard sol. M-200.7-IPC-02 (5E)CL01.13722*ICP-EPA Methods (Method 200.7 Version 4.4, May 1994) - Instrument Performance Check (IPC) Contains 5 elements in 5% HNO3 + traces HF (M-I C P M U L T I E L E MMulti Element ICP PLASOL Standard sol. M-200.7-PLASOL-1 (4E)CL01.13723 *ICP-EPA Methods (Method 200.7 Version 4.4, May 1994) - Plasma Solution (PLASOL) - Determining optimum viewing height of the plasma analytical zone.Multi Element ICP CAL Standard sol. M-200.7-03R (4E)CL01.13703Multi Element ICP TUNSOL Standard sol. M-200.7-TUNSOL-1 (2E)CL01.13724 *ICP-EPA Methods (Method 200.7 Version 4.4, May 1994) - Tuning Solution (TUNSOL) - Adjusting the aerosol argon gas flow prior to calibration and analysis.Multi Element ICP QC Standard sol. (QCS-01) (23E)CL01.13601Multi Element ICP INT Standard sol. INT-B1 (12E)CL01.13682I C P M U L T I E L E MMulti Element ICP QC Standard sol. (QCS-02) (7E)CL01.13602Multi Element ICP CAL Standard sol. MCS-01 (6E)CL01.13731 *ICP-EPA Methods (Methods 6010A - 6010B - 200.7 Version 3.3 and earlier) - Mixed Calibration Standard 1 Contains 6 elements in 2% HNO3 (MCS-Multi Element ICP Standard sol. PLASOL-R (5E)CL01.13822A Certificate of Analysis is provided with each ICP standard stating:- Actual certified concentration of the final solution- Traceability to NIST- Expiration date- Trace impurities detected。

new balance新百伦各种跑鞋材质介绍Air Mash透气网面:透气舒适,有效把湿气排走,令足部时刻保持干爽。

常见于:跑步鞋。

GORE-TEX®防水材GORE-TEX® 防水材料使鞋子更耐用,同时又能提供防水透气的功能,令足部时刻保持干爽,即使在极端的环境下也可以保持双足温暖干爽。

SURE-LACE®莲藕式鞋带莲藕式鞋带是一种电脑针织花边的往返式波形设计。

它在高强度的运动或者恶劣的条件下都不容易松开。

这种鞋带的设计为消费者提供了多种系带方式(紧紧地系在鞋舌上或者松散地系在鞋面上)。

因此,它提供了最佳的舒适性常见于:高端跑鞋。

N-LOCK®综合系带系统N-LOCK® 系统是透过在鞋面所缝上的「N」字及鞋带束缚的方式,来加强对足部的支撑。

鞋带会穿过鞋面每一边「N」字上的圈,当你在拉紧鞋带时,这个「N」字被拉紧压向中足上半部周围,加强对中足上半部的支撑及保持脚形美观。

Toe Protect™脚趾保护技术这项鞋面技术能保护脚趾免受石块、植物根茎及其他障碍物的撞击。

常见于:跑步鞋。

C-CAP® 柔软避震中底C-CAP® 柔软避震中底是由多层压缩的EVA 泡沫组成。

New Balance 将6 至8 英寸厚的EVA 压缩进中底倒模,令中底具有持久的避震功能。

常见于:复古鞋。

ENCAP® 避震中底由聚氨酯(TPU)包裹EVA 泡沫组成。

聚氨酯是非常耐用的材料,要将聚氨挤压是一件非常困难的事。

相反地,ENCAP® 的泡沫核心柔软,能有效避震。

将聚氨酯和EVA 泡沫结合,既能使鞋更耐用,又能为足部提供强劲的稳定性。

ACTEVA®避震材料由Dupont™Engage® 材料所制成,比一般泡沫聚酯物轻12%,是一种极为轻量及耐用的泡沫聚酯物。

轻质ACTEVA®避震材料置于鞋身中底的优质轻量泡沫聚酯物,含有抗压分子,由Dupont™Elvaloy® 材料制成,比一般泡沫聚酯物轻24%。

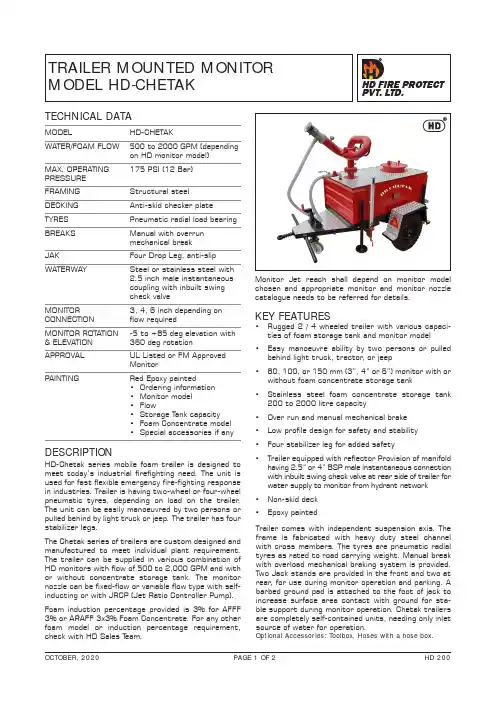

TRAILER MOUNTED MONITOR MODEL HD-CHETAKDESCRIPTIONHD-Chetak series mobile foam trailer is designed tomeet today’s industrial firefighting need. The unit is used for fast flexible emergency fire-fighting response in industries. Trailer is having two-wheel or four-wheel pneumatic tyres, depending on load on the trailer . The unit can be easily manoeuvred by two persons or pulled behind by light truck or jeep. The trailer has four stabilizer legs.The Chetak series of trailers are custom designed and manufactured to meet individual plant requirement. The trailer can be supplied in various combination of HD monitors with flow of 500 to 2,000 GPM and with or without concentrate storage tank. The monitor nozzle can be fixed-flow or variable flow type with self-inducting or with JRCP (Jet Ratio Controller Pump).Foam induction percentage provided is 3% for AFFF 3% or ARAFF 3x3% Foam Concentrate. For any other foam model or induction percentage requirement, check with HD Sales T eam.TECHNICAL DATAMODEL HD-CHETAK WATER/FOAM FLOW 500 to 2000 GPM (dependingon HD monitor model)MAX. OPERATING 175 PSI (12 Bar)PRESSURE FRAMING Structural steelDECKING Anti-skid checker plate TYRES Pneumatic radial load bearing BREAKS Manual with overrunmechanical break JAK Four Drop Leg, anti-slip WATERWAY Steel or stainless steel with 2.5 inch male instantaneous coupling with inbuilt swingcheck valveMONITOR 3, 4, 6 inch depending on CONNECTION flow requiredMONITOR ROTATION -5 to +85 deg elevation with & ELEVATION360 deg rotationAPPROVAL UL Listed or FM Approved Monitor PAINTING Red Epoxy painted • Ordering information• Monitor model• Flow • Storage Tank capacity • Foam Concentrate model• Special accessories if anyMonitor Jet reach shall depend on monitor model chosen and appropriate monitor and monitor nozzle catalogue needs to be referred for details.KEY FEATURES• Rugged 2 / 4 wheeled trailer with various capaci-ties of foam storage tank and monitor model • Easy manoeuvre ability by two persons or pulledbehind light truck, tractor , or jeep•80, 100, or 150 mm (3”, 4” or 6”) monitor with or without foam concentrate storage tank• Stainless steel foam concentrate storage tank 200 to 2000 litre capacity• Over run and manual mechanical brake • Low profile design for safety and stability• Four stabilizer leg for added safety• Trailer equipped with reflector Provision of manifoldhaving 2.5” or 4” BSP male instantaneous connection with inbuilt swing check valve at rear side of trailer for water supply to monitor from hydrant network • Non-skid deck • Epoxy paintedTrailer comes with independent suspension axis. The frame is fabricated with heavy duty steel channel with cross members. The tyres are pneumatic radial tyres as rated to road carrying weight. Manual break with overload mechanical braking system is provided. Two Jack stands are provided in the front and two at rear , for use during monitor operation and parking. A barbed ground pad is attached to the foot of jack to increase surface area contact with ground for sta-ble support during monitor operation. Chetak trailers are completely self-contained units, needing only inlet source of water for operation.Optional Accessories: Toolbox, Hoses with a hose box.LIMITED WARRANTYHD FIRE PROTECT PVT. L TD. hereby referred to as HD FIRE warrants to the original purchaser of the fire protection products manufactured by HD FIRE and to any other person to whom such equipment is transferred, that such products will be free from defect in material and workmanship under normal use and care, for two (2) years from the date of shipment by HD FIRE. Products or Components supplied or used by HD FIRE, but manufactured by others, are warranted only to the extent of the manufacturer’s warranty. No warranty is given for product or components which have been subject to misuse, improper installation, corrosion, unauthorized repair , alteration or un-maintained. HD FIRE shall not be responsible for system design errors or improper installation or inaccurate or incomplete information supplied by buyer or buyer’s representatives.HD FIRE will repair or replace defective material free of charge, which is returned to our factory, transportation charge prepaid, provided after our inspection the material is found to have been defective at the time of initial shipment from our works. HD FIRE shall not be liable for any incidental or consequential loss, damage or expense arising directly or indirectly from the use of the product including damages for injury to person, damages to property and penalties resulting from any products and components manufactured by HD FIRE. HD FIRE shall not be liable for any damages or labour charges or expense in making repair or adjustment to the product. HD FIRE shall not be liable for any damages or charges sustained in the adaptation or use of its engineering data & services. In no event shall HD Fire’s product liability exceed an amount equal to the sale price.The foregoing warranty is exclusive and in lieu of all other warranties and representation whether expressed, implied, oral or written, including but not limited to, any implied warranties or merchantability or fitness for a particular purpose. All such other warranties and representations are hereby cancelled.NOTICE :The equipment presented in this bulletin is to be installed in accordance with the latest publication standards of NFPA or other similar organisations and also with the provision of government codes or ordinances wherever applicable.The information provided by us is to the best of our knowledge and belief, and consist of general guidelines only. Site handling and installation control is not in our scope. Hence we give no guarantee for result and take no liability for damages, loss or penalties whatsoever , resulting from our suggestion, information, recommendation or damages due to our product.Product development is a continuous programme of HD FIRE PROTECT PVT. L TD. and hence the right to modify any specification without prior notice is reserved with the company.D-6/2, ROAD NO. 34, WAGLE INDUSTRIAL ESTATE, THANE 400 604, INDIA.• TEL: + (91) 22 2158 2600 • FAX: +(91) 22 2158 2602•EMAIL:***************• WEB: HD FIRE PROTECT PVT . LTD.Protecting What Matters Most to YouINSPECTION AND MAINTENANCEEnsure that trailers are visually inspected every month.Just like any equipment, a well-maintained trailer will perform better and last longer than a neglected one. Routine monthly visual and operational maintenance is recommended.The maintenance department must carry out routine jobs like lubricating moving parts and checking tyre pressure. Cleaning of trailers need to be carried out every month or as required to ensure smooth opera-tion. The unit must be operated at least once in six months or as per local authority having jurisdiction.1. Never start water flow unless the four drop legsare lowered and having full ground support and locked. Apply hand break. 2. Water flow must be started gradually and similarlymust be lowered gradually.3. The trailer is to be used inside industrial premises.HD Fire does not provide any vehicle/trailer road transport approval, certification, or registration, if applicable then owner/ buyer is responsible to obtain the same from local authority having juris-diction.NOTE ON FOAM CONCENTRATE:When using AFFF or AR-AFFF type foam concentrate in the storage tank, it is recommended by HD Fire that a thin layer (approximately 1/4 inch) of a qual-ity mineral oil be placed on the surface of the foam concentrate after filling the tank with the correct quantity. This alleviates the problem associated with evaporation of the foam concentrate.The foam concentrate should be inspected periodi-cally following any of these standards: NFPA 11, EN 13565-2, or any other relevant standards or as per authority having jurisdiction. For tanks containing mineral oil, special tools should be used during annual sampling exercise to make sure no oil is taken with the foam. Consult foam concentrate manufacturer .。

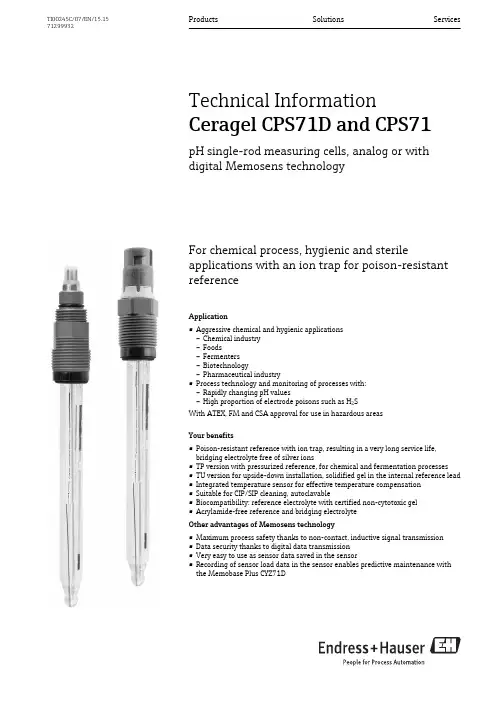

For chemical process, hygienic and sterileapplications with an ion trap for poison-resistant referenceApplication•Aggressive chemical and hygienic applications –Chemical industry –Foods–Fermenters –Biotechnology–Pharmaceutical industry•Process technology and monitoring of processes with:–Rapidly changing pH values–High proportion of electrode poisons such as H 2S With ATEX, FM and CSA approval for use in hazardous areas Your benefits•Poison-resistant reference with ion trap, resulting in a very long service life,bridging electrolyte free of silver ions•TP version with pressurized reference, for chemical and fermentation processes •TU version for upside-down installation, solidified gel in the internal reference lead •Integrated temperature sensor for effective temperature compensation •Suitable for CIP/SIP cleaning, autoclavable•Biocompatibility: reference electrolyte with certified non-cytotoxic gel •Acrylamide-free reference and bridging electrolyte Other advantages of Memosens technology •Maximum process safety thanks to non-contact, inductive signal transmission •Data security thanks to digital data transmission •Very easy to use as sensor data saved in the sensor•Recording of sensor load data in the sensor enables predictive maintenance with the Memobase Plus CYZ71DProducts Solutions ServicesTechnical InformationCeragel CPS71D and CPS71pH single-rod measuring cells, analog or with digital Memosens technologyTI00245C/07/EN/15.1571299932Ceragel CPS71D and CPS712Endress+HauserFunction and system designMeasuring principlepH measurementThe pH value is used as a unit of measurement for the acidity or alkalinity of a liquid medium. The membrane glass of the electrode supplies an electrochemical potential which is dependent upon the pH value of the medium. This potential is generated by the selective penetration of H + ions through the outer layer of the membrane. An electrochemical boundary layer with an electric potential forms at this point. An integrated Ag/AgCl reference system serves as the required reference electrode.The transmitter converts the measured voltage into the corresponding pH value using the Nernst equation.Measuring systemA complete measuring system consists of the following components at least:•pH electrode CPS71D or CPS71•Transmitter, e.g. Liquiline CM42, CM44x/R, Mycom S CPM153, Liquisys M CPM2x3•Memosens data cable CYK10 for Memosens sensors or CPK9 for analog sensors •Immersion, flow or retractable assembly, e.g. Cleanfit CPA871/8753412A00257571Example of a measuring system for pH measurement 1Retractable assembly Cleanfit CPA8712pH electrode CPS71D3Memosens data cable CYK104Liquiline M CM42 two-wire transmitter for hazardous areaCeragel CPS71D and CPS71Endress+Hauser 3Communication and data processing CPS71DCommunication with the transmitterAlways connect digital sensors with Memosens technology to a transmitter with Memosens technology. Data transmission to a transmitter for analog sensors is not possible.Digital sensors can store measuring system data in the sensor. These include the following:•Manufacturer data –Serial number –Order code–Date of manufacture •Calibration data –Calibration date–Slope at 25 °C (77 °F)–Zero point at 25 °C (77 °F)–Temperature offset –Number of calibrations–Serial number of the transmitter used to perform the last calibration •Operating data–Temperature application range –pH application range–Date of initial commissioning –Maximum temperature value–Hours of operation under extreme conditions –Number of sterilizations–Resistance of glass membraneYou can display the abovementioned data using the Liquiline CM44x, CM42 and Memobase Plus CYZ71D.Ceragel CPS71D and CPS714Endress+HauserDependabilityReliabilityEasy handlingSensors with Memosens technology have an integrated electronics unit that stores calibration data and other information (e.g. total operating hours and operating hours under extreme measuring conditions). Once the sensor has been connected, the sensor data are transferred automatically to the transmitter and used to calculate the current measured value. As the calibration data are stored in the sensor, the sensor can be calibrated and adjusted independently of the measuring point. The result:•Easy calibration in the measuring lab under optimum external conditions increases the quality of the calibration.•Pre-calibrated sensors can be replaced quickly and easily, resulting in a dramatic increase in the availability of the measuring point .•Maintenance intervals can be defined based on all stored sensor load and calibration data and predictive maintenance is possible.•The sensor history can be documented using external storage media and evaluation programs, e.g.Memobase Plus CYZ71D. Thus, the current application of the sensors can be made to depend on their previous history.IntegrityData security thanks to digital data transmissionMemosens technology digitizes the measured values in the sensor and transmits the data to the transmitter using a non-contact connection that is free from potential interference. The result:•Automatic error message if sensor fails or connection between sensor and transmitter is interrupted•Immediate error detection increases measuring point availabilitySafetyMaximum process safetyWith inductive transmission of the measured value using a non-contact connection, Memosens guarantees maximum process safety and offers the following benefits:•All problems caused by moisture are eliminated:–Plug-in connection free from corrosion–Measured values cannot be distorted by moisture.–Can even be connected under water•The transmitter is galvanically decoupled from the medium. Issues concerning "symmetrical high-impedance" or "asymmetry" or an impedance converter are a thing of the past.•EMC safety is guaranteed by screening measures for the digital transmission of measured values.•Intrinsically safe electronics mean operation in hazardous areas is not a problem.Ceragel CPS71D and CPS71Endress+Hauser 5InputMeasured variablespH value TemperatureMeasuring rangeElectrode version TB, TC:pH:0 to 14 pHTemperature:•0 to 140 °C (32 to 284 °F)•0 to 135 °C (32 to 275 °F) for sensors with Ex approval and analog sensorsElectrode version TP (pressurized reference):pH:0 to 12 pH Temperature:•0 to 140 °C (32 to 284 °F)(140 °C (284 °F) only for sterilization)•0 to 135 °C (32 to 275 °F) for sensors with Ex approval and analog sensors(135 °C (275 °F) only for sterilization)•Max. 100 °C (212 °F) in continuous operation due to increasing pressure loss at T > 100 °C (212 °F)Electrode version TU:pH:0 to 14 pH Temperature:•0 to 140 °C (32 to 284 °F)(140 °C (284 °F) only for sterilization)•0 to 135 °C (32 to 275 °F) for sensors with Ex approval and analog sensors(135 °C (275 °F) only for sterilization)•Max. 100 °C (212 °F) in continuous operation due to liquefaction ofgel-based inner electrolyte at T > 100 °C (212 °F)Please note the process operating conditions.Ceragel CPS71D and CPS716Endress+HauserInstallationInstallation instructions•Electrode versions TB, TC and TPDo not install the electrodes upside down. The angle of inclination must be at least 15° from the horizontal. A smaller inclination angle is not permitted as it could cause an air bubble to form in the glass sphere and prevent the inner electrolyte from completely wetting the pH diaphragm.•Electrode version TUThis electrode is suitable for upside-down installation. You can install it at any angle.Before screwing in the electrode, make sure the assembly threaded connection is clean and runs smoothly.‣Screw in the electrode finger-tight (3 Nm)! (Data apply only if installing withEndress+HauserOPA assemblies.)‣Make sure to follow the installation instructions in the Operating Instructions of the usedassembly.2Installation of electrode versions TB, TC, TP;installation angle at least 15° from the horizontal A Permitted orientation BForbidden orientation3Installation of electrode version TU; any installation angleInstallation instructions for electrode version TPL CAUTIONSudden rupture and flying glass splinters from the glass electrode with pressurized reference (approx. 7 bar abs. internal pressure)‣Always wear protective goggles when working with these electrodes‣Be particularly careful when removing the silicone seal on the reference junction. Here, a knife isused to activate the electrode for measuring operation.Before commissioning the electrode, you must remove the silicone seal from the junction. The pH value can only be measured properly once the seal has been removed.To do this, proceed as follows:ing the knife supplied, completely remove the silicone seal from the junction.2.To ensure optimum accuracy with this as with all pH electrodes, place the electrode in acalibration standard buffer solution with a pH of between 4 and 9 for 15-20 minutes prior to calibration.3.Put the electrode into operation.Ceragel CPS71D and CPS71Endress+Hauser 7Environment‣The sensor must not be used if the temperature drops below –15 °C (5 °F).Storage temperature 0 to 50 °C (32 to 122 °F)Degree of protectionIP 68:Memosens plug-in head, (10 m (33 ft) water column, 25 °C (77 °F), 45 days, 1 M KCl)IP 68:ESA plug-in head (1 m (3.3 ft) water column, 50 °C (122 °F), 168 h)IP 67:GSA plug-in head (with closed connector system)ProcessProcess temperatureElectrode version TB, TC:0 to 140 °C (32 to 284 °F)0 to 135 °C (32 to 275 °F) for sensors with Ex approval and analog sensorsElectrode version TP, TU:0 to 100 °C (32 to 212 °F)(sterilizable up to 140 °C (284 °F) / 135 °C (275 °F) for sensors with Ex approval and analog sensors)Process pressure (absolute)Electrode version TB, TC: 1 to 14 bar (15 to 203 psi)Electrode version TU: 1 to 11 bar (15 to 159 psi)Electrode version TP:1 to 7 bar (15 to 101 psi)Minimum 0.8 bar abs. is possible. Be aware of quick KCl consumption.L CAUTIONPressurization of sensor due to prolonged use under increased process pressure Risk of injury from glass breakage‣Avoid excessive heating of such sensors if using them under reduced process pressure or underatmospheric pressure.‣When handling such sensors, wear protective goggles and suitable gloves.4Pressure-temperature ratingsA Version TB, TCB Version TB, TC with Ex approval and analog sensors C Version TUD Version TPEAtmospheric pressureMinimum conductivity 10 μS/cm (at atmospheric pressure, without flow)Ceragel CPS71D and CPS718Endress+HauserpH rangeElectrode version TB, TC, TU:0 to 14 pH Electrode version TP:0 to 12 pHRisk of damage to electrode‣Never use the electrode outside of the listed specifications!Mechanical constructionDesign, dimensions CPS71D5CPS71D with Memosens plug-in head, TB 1Memosens plug-in head2Viton O-ring with thrust collar3Ag/AgCl reference lead with ion trap 4Junction5Temperature sensor6Ag/AgCl internal reference lead - pH 7pH glass membrane6CPS71D with Memosens plug-in head, TP 1Memosens plug-in head2Viton O-ring with thrust collar 3Spacer4Pressure indicator with air bubble 5Ag/AgCl reference lead with ion trap 6Junction7Temperature sensor8Ag/AgCl internal reference lead - pH 9pH glass membraneCeragel CPS71D and CPS71Endress+Hauser 97CPS71 with GSA plug-in head, TB 1GSA electrode plug-in head, Pg 13.52Viton O-ring with thrust collar3Ag/AgCl reference lead with ion trap 4Junction5Ag/AgCl internal reference lead - pH 6pH glass membrane8CPS71 with ESA plug-in head, TC 1ESA electrode plug-in head, Pg 13.52Viton O-ring with thrust collar3Ag/AgCl reference lead with ion trap 4Junction5Temperature sensor6Ag/AgCl internal reference lead - pH 7pH glass membraneCeragel CPS71D and CPS7110Endress+Hauser9CPS71 with ESA plug-in head, TP 1ESA electrode plug-in head, Pg 13.52Viton O-ring with thrust collar 3Spacer4Pressure indicator with air bubble 5Ag/AgCl reference lead with ion trap 6Junction7Temperature sensor8Ag/AgCl internal reference lead - pH 9pH glass membraneWeight 0.1 kg (0.22 lbs) for a length of 120 mm (4.72 inch)MaterialsElectrode shaft:Glass to suit process pH membrane glasses:Type B Metal lead:Ag/AgClDiaphragm:Ceramic, sterilizable and autoclavable Reference and bridging electrolyte gel:Acrylamide-freeProcess connection Pg 13.5Temperature sensorCPS71D:NTC30K CPS71:Pt100, Pt1000Plug-in heads CPS71D:Memosens plug-in head for digital, non-contact data transmission, 17 bar abs.(246 psi), Ex or non-ExCPS71:ESA:Threaded plug-in head Pg 13.5, TOP68, 17 bar abs. (246 psi), Ex GSA:Threaded plug-in head Pg 13.5, non-ExCeragel CPS71D and CPS71Endress+Hauser 11Reference system Electrode version TB, TC:Ag/AgCl reference lead with ion trap, reference and bridging electrolyte 3 M KCl, acrylamide-free, non-cytotoxic Electrode version TP:Ag/AgCl reference lead with ion trap, reference and bridging electrolyte 3 M KCl, acrylamide-free, non-cytotoxic, pressurized ion trap 7 bar abs.; indicated by pressure indicator (→ 10).Electrode version TU:Ag/AgCl reference lead with ion trap, reference and bridging electrolyte 3 M KCl, acrylamide-free Detail A10Pressure indicator of electrode version TPCertificates and approvalsEx approval CPS71D and CPS71 (ESA)ATEX/NEPSI II 1G Ex ia IIC T3/T4/T6 GaFM/CSA IS/NI CL. I. Div 1, Group A-DHazardous area versions of the digital sensors with Memosens technology are indicated by a red-orange ring in the plug-in head.Biocompatibility Cytotoxicity tested to:•ISO 10993-5:2009•USP 37: 2014, chapter <87> for reference electrolyte gelTÜV certificate for Memosens and ESA plug-in headPressure resistance 16 bar rel. (232 psi), minimum three times the safety pressure Electromagnetic compatibility CPS71D Interference emission and interference immunity as per EN 61326: 2012Ceragel CPS71D and CPS7112Endress+HauserOrdering informationProduct page /cps71d /cps71Product Configurator The navigation area is located on the right of the product page.1.Under "Device support" click "Configure your selected product". The Configurator opens in a separate window.2.Select all the options to configure the device in line with your requirements. In this way, you receive a valid and complete order code for the device.3.Export the order code as a PDF or Excel file. To do so, click the appropriate button at the top of the screen.Scope of delivery The scope of delivery includes:•Sensor in the version ordered •Technical InformationAccessoriesThe following are the most important accessories available at the time this documentation was issued. For accessories not listed here, please contact your service or sales office.Assemblies Cleanfit CPA472D •Robust retractable assembly for pH, ORP and other industrial sensors •Heavy-duty version made of durable materials •For manual or pneumatic, remote-controlled operation •Product Configurator on the product page: /cpa472dTechnical Information TI00403CCleanfit CPA871•Flexible process retractable assembly for water, wastewater and the chemical industry •For applications with standard 12mm sensors •Product Configurator on the product page: /cpa871Technical Information TI01191CCleanfit CPA875•Retractable process assembly for sterile and hygienic applications •For in-line measurement with standard 12 mm sensors for parameters such as pH, ORP and oxygen •Product Configurator on the product page: /cpa875Technical Information TI01168CCleanfit CPA450•Manual retractable assembly for installing 120 mm sensors in tanks and pipes •Product Configurator on the product page: /cpa450Technical Information TI00183CCleanfit CPA471•Compact stainless steel retractable assembly for installation in tanks and pipes, for manual or pneumatically remote-controlled operation •Product Configurator on the product page: /cpa471Technical Information TI00217CCeragel CPS71D and CPS71Endress+Hauser 13Cleanfit CPA472•Compact plastic retractable assembly for installation in tanks and pipes •For manual or pneumatic, remote-controlled operation •Product Configurator on the product page: /cpa472Technical Information TI00223CCleanfit CPA473•Stainless steel process retractable assembly with ball valve shutoff for particularly reliable separation of the medium from the environment •Product Configurator on the product page: /cpa473Technical Information TI00344CCleanfit CPA474•Plastic process retractable assembly with ball valve shutoff for particularly reliable separation of the medium from the environment •Product Configurator on the product page: /cpa474Technical Information TI00345CUnifit CPA442•Installation assembly for food, biotechnology and pharmaceutics •With EHEDG and 3A certificate •Product Configurator on the product page: /cpa442Technical Information TI00306CDipfit CPA111•Immersion and installation assembly made of plastic for open and closed vessels •Product Configurator on the product page: /cpa111Technical Information TI00112CDipfit CPA140•pH/ORP immersion assembly with flange connection for very demanding processes •Product Configurator on the product page: /cpa140Technical Information TI00178CFlowfit CPA240•pH/ORP flow assembly for processes with stringent requirements •Product Configurator on the product page: /cpa240Technical Information TI00179CFlowfit CPA250•Flow assembly for pH/ORP measurement •Product Configurator on the product page: /cpa250Technical Information TI00041CEcofit CPA640•Set comprising adapter for 120 mm pH/ORP electrodes and sensor cable with TOP68 coupling •Product Configurator on the product page: /cpa640Technical Information TI00246CFlexdip CYA112•Immersion assembly for water and wastewater •Modular assembly system for sensors in open basins, channels and tanks •Product Configurator on the product page: /cya112Technical Information TI00432CCeragel CPS71D and CPS7114Endress+HauserBuffer solutions High-quality buffer solutions from Endress+Hauser - CPY20The secondary buffer solutions have been referenced to primary reference material of the PTB (German Federal Physico-technical Institute) and to standard reference material of NIST (National Institute of Standards and Technology) according to DIN 19266 by a DKD (German Calibration Service) accredited laboratory.Product Configurator on the product page: /cpy20Measuring cableCYK10 Memosens data cable •For digital sensors with Memosens technology •Product Configurator on the product page: /cyk10Technical Information TI00118CCPK9•Terminated measuring cable for connecting analog sensors with TOP68 plug-in head •Selection in accordance with product structureFor more information and to order, please contact your sales office.CPK1For pH/ORP electrodes with GSA plug-in headOrdering information is available from your sales office or at .。

彪马anti shock system缓震原理一、引言彪马是一家德国运动品牌,其anti shock system缓震系统是其产品的一个重要特点。

本文将深入探讨彪马anti shock system缓震原理。

二、概述彪马anti shock system缓震系统是一种能够减少跑步时对脚底的冲击力的技术,它可以使跑步更加舒适和稳定。

这种技术在彪马的鞋子中得到了广泛应用,并被认为是彪马鞋子优秀性能的一个关键因素。

三、原理1. 缓震材料彪马anti shock system缓震系统采用了高科技材料,如EVA(乙烯-乙烯醋酸乙烯共聚物)和PU(聚氨酯)等。

这些材料可以有效地吸收和分散跑步时脚底所受到的冲击力。

2. 空气垫除了缓震材料外,彪马anti shock system还采用了空气垫技术。

这些空气垫可以进一步减少跑步时对脚底的冲击力,从而提高跑步的舒适性和稳定性。

3. 鞋底结构彪马anti shock system缓震系统的鞋底结构也是其能够减少冲击力的一个关键因素。

鞋底采用了多层结构,其中包括缓震材料和空气垫等。

这种多层结构可以有效地分散跑步时脚底所受到的冲击力,并提高跑步的舒适性和稳定性。

四、应用彪马anti shock system缓震系统已经被广泛应用于彪马的跑步鞋中。

这些跑步鞋不仅具有出色的缓震性能,还具有舒适和稳定等其他优秀特点。

五、总结彪马anti shock system缓震系统是一种减少跑步时对脚底冲击力的技术,它采用了高科技材料、空气垫和多层鞋底结构等技术手段。

这种技术已经被广泛应用于彪马的跑步鞋中,并成为彪马产品优秀性能的一个重要特点。

fitfoam的名词解释fitfoam是一种广泛应用于运动鞋和运动装备中的材料技术。

它的独特性能和多功能性使其成为许多运动品牌钟爱的选择。

本文将解释fitfoam的定义、优势以及在不同领域中的应用。

在定义方面,fitfoam是一种高级聚合物发泡材料,主要由聚氨酯(polyurethane)制成。

它采用了独特的制造工艺,通过将聚氨酯与气体混合并加热发泡,使其成为轻质、柔软而具有弹性的材料。

fitfoam的特殊结构和特点使其在各种运动鞋和装备中具备出色的性能。

首先,fitfoam具有优异的缓震性能。

由于其独特的气泡结构,fitfoam能够在运动时吸收和分散来自地面的冲击,从而减轻对身体的压力和疲劳感。

这使得运动者在长时间的训练和比赛中能够更加舒适地运动,并减少受伤的风险。

其次,fitfoam具有极佳的透气性。

这得益于其开放式的细孔结构,可以有效地通风和排汗。

透气性良好的fitfoam使脚部能够保持干爽和舒适,减少细菌滋生的机会,有助于预防脚气和其他脚部问题。

另外,fitfoam还具有出色的回弹性能。

其弹性材料能够在受力后快速恢复原状,提供额外的支撑和稳定性。

这对于运动鞋来说尤为重要,因为它可以帮助运动者在锻炼时保持良好的姿势和平衡,并减少因不稳定而引起的扭伤和摔倒的风险。

在应用方面,fitfoam广泛用于各种运动鞋款式中,包括跑鞋、篮球鞋、足球鞋等。

它可以作为鞋垫、中底或鞋面的一部分,为运动鞋提供额外的舒适性和性能优势。

除了运动鞋,fitfoam还常用于运动装备中,如护膝、护腕等。

通过使用fitfoam材料,这些装备能够提供更好的保护和支撑,有助于预防运动损伤。

此外,fitfoam也在医疗保健领域得到应用。

由于其出色的缓冲性能,fitfoam被用于制作矫形鞋垫和康复辅助器具。

这些产品能够为需要额外支撑和缓解的人提供个性化的护理和舒适性,减轻关节和骨骼的负担,促进康复过程。

总而言之,fitfoam是一种具有优异性能的聚合物发泡材料,广泛应用于运动鞋和运动装备中。

Château Plince 2019Pomerol2019 Vintage Blend: 81% Merlot - 19% Cabernet FrancChateau Plince Pomerol is one of those properties where modernity issynonymous with tradition. This area, in the family for over a century,has kept its authenticity while taking advantage of technologicaladvances in a constant concern for quality.Appellation: PomerolOwner: SCEV MoreauVineyard size: 8.66 hectares (21.2 acres)Soil Types:Dark soil on iron panVineyard grape varietals:72% Merlot - 23% Cabernet Franc - 5% Cabernet SauvignonViticulture: Culture raisonnée. Vine growth management adapted to the climatic conditions Harvest: ManualHarvest dates: September 27th to October 10th 2019Winemaking: In thermo-regulated concrete vats. Malolactic fermentation in oak barrels Aging: 12-18 months in oak barrels. 12-18 months in French oak barrels(1/3 new, 1/3 1 year old, 1/3 2 years old)HistoryChâteau Plince is situated just outside the village of Catusseau in Pomerol, and has been owned by the Moreau family for over four generations. The vineyard, planted on dark sand with an iron-rich subsoil, is made up of one block and counts Châteaux Nenin and La Pointe as its neighbors.The vineyard is tended traditionally and with great care throughout the year (leafthinning, green harvests) in order to produce optimally ripe fruit that is expressive of this terroir. After harvest, the grapes undergo a care-ful sorting before being transferred to thermo-regulated cement tanks, where they are stored for one week of pre-fermentation maceration. Fermentation lasts for 1-2 weeks, and after 1-2 weeks of additional macera-tion, the wine is transferred to French oak barrels (1/3 new) for the malolactic fermentation, followed by 12-18 months of aging. Château Plince produces a classic Pomerol with the beautiful fruit, depth and concentration typical of this appellation.2019 Vintage:After a mild winter, spring alternated between sun and rain. Narrowly escaping a frost on April 13th, it was the rain in early June that first influenced the vintage. Indeed, the flowering suffered as a result and Merlot grapes counted an average of just 120 berries (instead of 200 usually). Confirming global warming trends, the sum-mer was exceptionally sunny and warm, just missing the historic record for hours of sunshine set in 2018. On the gravel plateau of Pomerol, hydric stress set in as early as mid-July. Happily, we received gentle, favor-able rain on July 26th (1.4 inches) that set off a quick and even veraison. This moment marked the qualitative turn of the vintage. At the end of August, Merlot grapes weighed 1.2 grams on average (instead of 1.5 grams in a normal vintage), heralding exceptional concentration but low yields. Graced by fine weather, Château Plince harvested optimally ripe grapes from September 27th until October 10th.James Suckling - 94 PointsBlueberries and cocoa powder, as well as lavender and blackberries on the nose. Full-bodiedwith tight, focused tannins that are lean and racy, in a clear way. Just a hint of tar andash at the end. Chewy and fine. Best after 2027.Also:Vinous-90+ Pts, Wine Advocate-90-92 Pts.。

40塑料助剂2020年第1期(总第139期)性能与分析........抗氧剂对聚瞇抗老化性能的影响陈金彪安平孙文佳(天津利安隆新材料股份有限公司,天津,300480)摘要:不同聚醛由于其下游应用需求不同,对抗氧剂的需求也不同。

普通软泡聚瞇在发泡应用时由于发泡配方中含水量高,发泡温度比较高,泡沫的烧芯问题是抗氧剂要解决的关键问题,U-pack B7033可以满足应用需求;对于高回弹聚瞇,由于其主要应用是汽车领域,除了考虑泡沫的抗烧芯性能外,还要考虑添加的抗氧剂对聚瞇及聚氨酯泡沫的醛酮含量以及VOC的影响,U-pack B7170可以满足应用要求;CASE聚醛用抗氧剂除了要考虑聚瞇的储存稳定性外,还要考虑下游制备聚氨酯预聚体时的颜色稳定性,U-pack B7522可以满足应用要求。

关键词:抗氧剂聚瞇抗老化doi:10.3969/j.issn.l672-6294.2020.01.0006Effect of Antioxidants on Anti-aging Properties of Polyether PolsChen Jinbiao An Ping Sun Wenjia(Tianjin Anlong New Material Co.,Ltd.,Tianjin»300480)Abstract:Different polyether pols have different requirements for anti-aging additives(antioxidants)due to their different downstream application requirements.Flexible foam pols in foaming application due to the high water content in the foaming formula,the foaming temperature is relatively high,the scorching problem of the foam is the key problem to be solved for the anti-aging additive,in this way U-pack B7033can meet the application requirements.For high resilience pols,since it is mainly used in the automotive field,in addition to the anti-scorching properties of the foam,the effect of the added anti-aging additives is also necessary to be considered on the aldehyde and ketone contents of the polyether and polyurethane foam as well as the VOC content,in this way U-pack B7170can meet the application requirements.For the CASE pols,in addition to the storage stability of polyether,the color stability should be also considered in the anti-aging additives in this way the prepared polyurethane prepolymer,U-pack B7522,can meet the application requirements.Keywords:antioxidant;polyether pols;anti-aging聚醯多元醇是由氧化烯怪和多轻基或胺类化合物进行开环均聚或共聚反应合成的主链含有醸键(一R—0—R—),端基或侧基含有大于2个短收稿日期:2019-10-30基(-OH)的低聚物。

Hyaluronic Acid Derivatives (Euflexxa™ & Gel-One®)Document Number: MH-0061 Last Review Date: 6/28/2016Date of Origin: 01/01/2012Dates Reviewed: 03/2012, 06/2012, 09/2012, 12/2012, 03/2013, 06/2013, 09/2013, 12/2013, 03/2014, 06/2014, 09/2014, 12/2014, 03/2015, 6/2015, 12/2015, 3/2016, 06/2016I.Important Note:a.Medica ONLY covers Gel-One and Euflexxa. All other Hyaluronic Acid Derivativeswill not be covered.II.Length of AuthorizationCoverage will be provided for six months and may be renewed.III.Dosing LimitsA.Quantity Limit (max daily dose) [Pharmacy Benefit]: per knee−Euflexxa: Maximum 6 injections per 180 days−Gel-One: Maximum 2 injections per 180 daysB.Max Units (per dose and over time) [Medical Benefit]:J7323 (Euflexxa) per knee (1 unit = 1 dose)Male 3 units every 180 days*Female 3 units every 180 days**Max units are doubled (6 billable units) when the claim is submitted with bilateral ICD 10 codes J7326 (Gel-One) per knee (1 unit = 1 dose)Male 1 unit every 180 days*Female 1 unit every 180 days**Max units are doubled (2 billable units) when the claim is submitted with bilateral ICD 10 codes IV.Initial Approval CriteriaCoverage is provided in the following conditions:Osteoarthritis of the knee †•Documented symptomatic osteoarthritis of the knee; AND•Trial and failure of conservative therapy (including physical therapy, pharmacotherapy [e.g., non-steroidal anti-inflammatory drugs (NSAIDs), acetaminophen (up to 1 g 4 times/day)and/or topical capsaicin cream]) has been attempted and has not resulted in functionalimprovement after at least 3 months; AND•The patient has failed to adequately respond to aspiration and injection of intra-articular steroids; AND•The patient reports pain which interferes with functional activities (e.g., ambulation, prolonged standing); AND•There are no contraindications to the injections (e.g., active joint infection, bleeding disorder) †FDA Approved Indication(s)V.Renewal CriteriaCoverage can be renewed based upon the following criteria:•The medical record demonstrates a reduction in the dose of NSAIDS (or other analgesics or anti-inflammatory medication) during the 6-month period following the previous series ofinjections; AND•The medical record objectively documents significant improvement in pain and functional capacity as the result of the previous injections; AND•Absence of unacceptable toxicity from the previous injectionsVI.Dosage/Administration (per knee)VII.Billing Code/Availability InformationJcode:•J7323 – Euflexxa – (Ferring) 20 mg injection: 1 billing unit = 20 mg (1 dose)•J7326 – Gel-One (Seikagaku) 30 mg injection: 1 billing unit = 30 mg (1 dose)NDC:•N/AVIII.References1.Euflexxa [package insert]. Parsippany, NJ; Ferring Pharmaceuticals; June 2015. AccessedApril 2016.2.Gel-One [package insert]. Tokyo, Japan; Seikagaku Corporation May 2011. Accessed April2016.3.McAlindon TE, Bannuru RR, Sullivan MC, et al. OARSI guidelines for the non-surgicalmanagement of knee osteoarthritis. Osteoarthritis Cartilage. 2014 Mar;22(3):363-88. doi:10.1016/j.joca.2014.01.003. Epub 2014 Jan 24.4.Brown GA. AAOS clinical practice guideline: treatment of osteoarthritis of the knee:evidence-based guideline, 2nd edition. J Am Acad Orthop Surg. 2013 Sep;21(9):577-9. doi:10.5435/JAAOS-21-09-5775.Wisconsin Physicians Service Insurance Corporation. Local Coverage Determination (LCD):Intra-articular Injections of Hyaluronan (L34525). Centers for Medicare & MedicaidServices, Inc. Updated on 12/22/2015 with effective date 1/1/2016. Accessed April 2016.6.Novitas Solutions, Inc. Local Coverage Determination (LCD): Hyaluronan Acid Therapiesfor Osteoarthritis of the Knee (L35427). Centers for Medicare & Medicaid Services, Inc.Updated on 1/22/2016 with effective date 1/1/2016. Accessed April 2016.7.Palmetto GBA. Local Coverage Determination (LCD): Hyaluronate Polymers (L33432).Centers for Medicare & Medicaid Services, Inc. Updated on 04/01/2016 with effective date04/07/2016. Accessed April 2016.8.First Coast Service Options, Inc. Local Coverage Determination (LCD):Viscosupplementation Therapy For Knee (L33767). Centers for Medicare & MedicaidServices, Inc. Updated on 4/07/2016 with effective date 04/01/2016. Accessed April 2016.9.National Government Services, Inc. Local Coverage Article: Hyaluronans (e.g.,Hyalgan ®,Supartz ®, Euflexxa™, Synvisc ®, Synvisc-One™, Orthovisc ®, Gel-One® ), Intra-articularInjections of - Related to LCD L25820 (A52420). Centers for Medicare & Medicaid Services,Inc. Updated on 12/24/2015 with effective date 1/1/2016. Accessed April 2016.Appendix 1 – Covered Diagnosis Codes (*Max Units for bilateral indications are doubled)M17.0 Bilateral primary osteoarthritis of knee*M17.10 Unilateral primary osteoarthritis, unspecified kneeM17.11 Unilateral primary osteoarthritis, right kneeM17.12 Unilateral primary osteoarthritis, left kneeM17.2 Bilateral post-traumatic osteoarthritis of knee*M17.30 Unilateral post-traumatic osteoarthritis, unspecified kneeM17.31 Unilateral post-traumatic osteoarthritis, right kneeM17.32 Unilateral post-traumatic osteoarthritis, left kneeM17.4 Other bilateral secondary osteoarthritis of knee*M17.5 Other unilateral secondary osteoarthritis of kneeM17.9 Osteoarthritis of knee, unspecifiedAppendix 2 – Centers for Medicare and Medicaid Services (CMS)Medicare coverage for outpatient (Part B) drugs is outlined in the Medicare Benefit Policy Manual (Pub. 100-2), Chapter 15, §50 Drugs and Biologicals. In addition, National Coverage Determination (NCD) and Local Coverage Determinations (LCDs) may exist and compliance with these policies is required where applicable. They can be found at: /medicare-coverage-database/search/advanced-search.aspx. Additional indications may be covered at the discretion of the health plan.Medicare Part B Covered Diagnosis Codes (applicable to existing NCD/LCD): Jurisdiction(s): 5, 8NCD/LCD Document (s): L34525https:///medicare-coverage-database/details/lcd-details.aspx?LCDId=34525&ver=14&Date=02%2f10%2f2016&DocID=L34525&SearchType=Ad vanced&bc=KAAAAAgAAAAAAA%3d%3d&Jurisdiction(s): 12 (L), H NCD/LCD Document (s): L35427https:///medicare-coverage-database/details/lcd-details.aspx?LCDId=35427&ver=16&Date=02%2f10%2f2016&DocID=L35427&SearchType=Ad vanced&bc=KAAAAAgAAAAAAA%3d%3d&Jurisdiction(s): 11(M)NCD/LCD Document (s): L33432https:///medicare-coverage-database/details/lcd-details.aspx?LCDId=33432&ver=11&Date=02%2f10%2f2016&DocID=L33432&SearchType=Ad vanced&bc=KAAAAAgAAAAAAA%3d%3d&Jurisdiction(s): 9(N)NCD/LCD Document (s): L33767https:///medicare-coverage-database/details/lcd-details.aspx?LCDId=33767&ver=10&Date=02%2f10%2f2016&DocID=L33767&SearchType=Ad vanced&bc=KAAAAAgAAAAAAA%3d%3d&Jurisdiction(s): 6, K NCD/LCD Document (s): A52420https:///medicare-coverage-database/details/article-details.aspx?articleId=52420&ver=11&Date=02%2f10%2f2016&DocID=A52420&SearchType=A dvanced&bc=JAAAAAgAAAAAAA%3d%3d&Jurisdiction Applicable State/US Territory ContractorE CA,HI, NV, AS, GU, CNMI Noridian Administrative Services (NAS)Noridian Administrative Services (NAS)F AK, WA, OR, ID, ND, SD, MT, WY,UT, AZ5 KS, NE, IA, MO Wisconsin Physicians Service (WPS)6 MN, WI, IL National Government Services (NGS)H LA, AR, MS, TX, OK, CO, NM Novitas Solutions8 MI, IN Wisconsin Physicians Service (WPS)9 (N) FL, PR, VI First Coast Service Options10 (J) TN, GA, AL Cahaba Government Benefit Administrators11 (M) NC, SC, VA, WV Palmetto GBA12 (L) DE, MD, PA, NJ, DC Novitas SolutionsK NY, CT, MA, RI, VT, ME, NH National Government Services (NGS)15 KY, OH CGS Administrators, LLC。