DMN500-48电源技术规格书V2.03

- 格式:pdf

- 大小:563.92 KB

- 文档页数:9

PUNP ELECTRONICDM500A模块板机组控制器厂家使用说明书在安装使用控制器之前,请详细阅读该使用说明书!邦普电脑技术开发有限公司2004/07/21软件功能码:DM500A-QHTH-F01M V1.02版权所有,翻版必究!目录一、概述 (1)二、控制器操作框架 (1)三、安装说明 (1)1、外观图 (1)2、外形安装尺寸图 (2)3、模块板的设置说明 (3)4、电源通讯连接示意图 (4)四、界面及操作说明 (5)1、用户操作 (5)(1)开机显示 (5)(2)用户主界面显示 (5)(3)用户查询操作 (6)(4)用户设置 (8)(5)参数设置 (9)2、控制逻辑 (12)(1)开机操作 (12)(2)停机操作 (12)(3)能量调节 (12)(5)故障制约关系 (13)(6)运行指示 (13)(7)报警指示 (13)(8)远程开关 (14)3、故障处理 (14)五、运行参数设置 (15)六、相关逻辑 (18)1、冬季防冻逻辑 (18)2、除霜逻辑 (18)3、电加热控制 (19)4、保护 (19)(1)、压缩机保护 (19)(2)、其他保护 (19)七、故障诊断 (19)1、故障显示 (19)2、故障编号及说明 (19)3、故障可能原因表 (20)附录1:风冷送水电气连接图 (22)附录4:版本更改说明 (23)一、概述控制器采用先进的、高集成度的一体化单片机,极大的提高了系统的抗干扰能力。

外型采用塑料外壳,安装方便。

前后板通过485通讯方式进行数据交换,整个系统既可以一体化安装,也可以进行分体式安装。

二、控制器操作框架三、安装说明1、外观图图 3-1开机画面厂家测试用户主监控界面用户查询操作 用户设置操作参数设置当前故障查询压机运行时间查 询系统时间查询 定时开停设置 初始化参数运行参数设置历史故障查询模块禁用设置修改密码系统时间设置 运行时间设定模块状态查询 强制 除霜面板正面如(图3-1)所示, 面板的外形尺寸为:长196mm×宽115.5mm。

电源技术规格书(客户承认书)SPECIFICATION FOR APPROV AL客户/ CUSTOMER: 光电显示客户物料号/CUSTOMER NO.:长城型号/ MODEL NO.: XSP200WV42B长城料号/ P/N .: 5171915电源版本/ POWER REV.: V01日期/ DATE: 2020.02.27客户确认签字,盖章后请回传一份承认书给我司。

Please return to us on copy of “SPECIFICATION FOR APPROV AL”with your approved signature.中国长城科技集团股份有限公司电源事业部China Greatwall Technology Group Co., LTD. Power Supply Division深圳宝安区石岩镇宝石东路长城工业园Great wall Industry Park, Baoshi East Rd, Shiyan Country, Baoan, ShenzhenTEL: 0755--29519374 / 26639997 FAX: 0755--29519395/power变更记录目录总则 (2)1 电气特性 (2)1.1输入特性 (2)1.1.1输入基本特性 (2)1.1.2输入保护特性 (2)1.2 输出特性 (2)1.2.1输出基本特性 (2)1.2.2输出保护特性 (3)1.2.3负载/温度曲线图&负载/输入电压曲线图 (3)2 环境 (4)3 电磁兼容性 (4)4 安规 (4)5 可靠性 (4)6 特殊要求 (4)7 外观结构 (5)7.1电源尺寸 (5)7.2标签图 (6)8 包装 (6)8.1电源净重 (6)8.2包装图 (6)8.3包装运输实验 (7)9条形码label说明 (7)10 使用注意事项 (8)10.1开箱检查 (8)10.2使用原则 (8)10.3安全注意事项 (8)11 产品保修 (8)11.1保修期限 (8)11.2维修范围 (8)11.3限制条款 (9)12 备注 (9)总则该款产品为AC转DC电源,90~264Vac交流输入,单路直流隔离输出,输出总功率168W,通过CCC、CE、UL认证,符合欧盟RoHS指令。

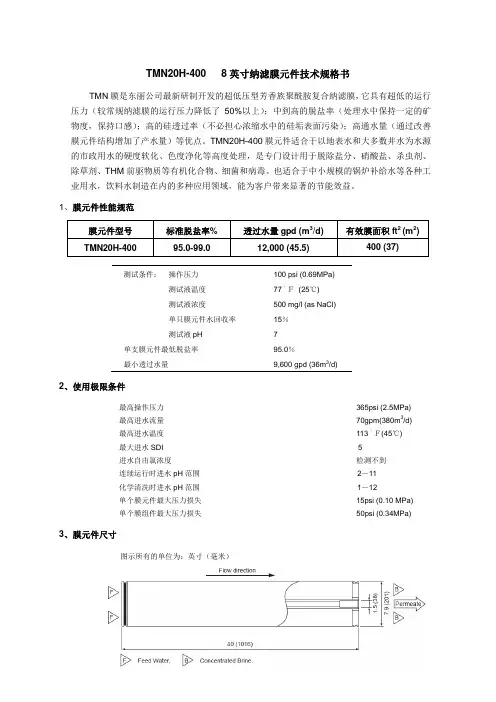

TMN20H-400 8英寸纳滤膜元件技术规格书TMN膜是东丽公司最新研制开发的超低压型芳香族聚酰胺复合纳滤膜,它具有超低的运行压力(较常规纳滤膜的运行压力降低了50%以上);中到高的脱盐率(处理水中保持一定的矿物度,保持口感);高的硅透过率(不必担心浓缩水中的硅垢表面污染);高通水量(通过改善膜元件结构增加了产水量)等优点。

TMN20H-400膜元件适合于以地表水和大多数井水为水源的市政用水的硬度软化、色度净化等高度处理,是专门设计用于脱除盐分、硝酸盐、杀虫剂、除草剂、THM前驱物质等有机化合物、细菌和病毒。

也适合于中小规模的锅炉补给水等各种工业用水,饮料水制造在内的多种应用领域,能为客户带来显著的节能效益。

1、膜元件性能规范膜元件型号标准脱盐率% 透过水量gpd (m3/d) 有效膜面积ft2 (m2)(45.5) 400 (37)TMN20H-400 95.0-99.0 12,000测试条件:操作压力100 psi (0.69MPa)测试液温度 77゚F (25℃)测试液浓度500 mg/l (as NaCl)单只膜元件水回收率 15%测试液pH 7单支膜元件最低脱盐率 95.0%最小透过水量9,600 gpd (36m3/d)2、使用极限条件最高操作压力·············································································365psi (2.5MPa)最高进水流量·············································································70gpm(380m3/d)最高进水温度·············································································113゚F(45℃)最大进水SDI (5)进水自由氯浓度··········································································检测不到连续运行时进水pH范围·······························································2-11化学清洗时进水pH范围·······························································1-12单个膜元件最大压力损失······························································15psi (0.10 MPa)单个膜组件最大压力损失······························································50psi (0.34MPa)3、膜元件尺寸图示所有的单位为:英寸(毫米)。

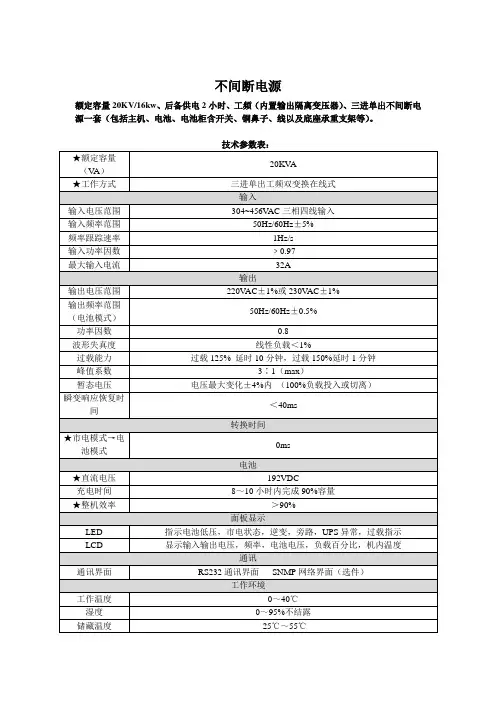

不间断电源额定容量20KV/16kw、后备供电2小时、工频(内置输出隔离变压器)、三进单出不间断电源一套(包括主机、电池、电池柜含开关、铜鼻子、线以及底座承重支架等)。

技术参数表:★额定容量20KVA(VA)★工作方式三进单出工频双变换在线式输入输入电压范围304~456V AC三相四线输入输入频率范围50Hz/60Hz±5%频率跟踪速率1Hz/s输入功率因数﹥0.97最大输入电流32A输出输出电压范围220V AC±1%或230V AC±1%输出频率范围50Hz/60Hz±0.5%(电池模式)功率因数0.8波形失真度线性负载<1%过载能力过载125% 延时10分钟,过载150%延时1分钟峰值系数3∶1(max)暂态电压电压最大变化±4%内(100%负载投入或切离)瞬变响应恢复时<40ms间转换时间★市电模式→电0ms池模式电池★直流电压192VDC充电时间8~10小时内完成90%容量★整机效率>90%面板显示LED 指示电池低压,市电状态,逆变,旁路,UPS异常,过载指示LCD 显示输入输出电压,频率,电池电压,负载百分比,机内温度通讯通讯界面RS232通讯界面SNMP网络界面(选件)工作环境工作温度0~40℃湿度0~95%不结露储藏温度-25℃~55℃噪音<55dB(距箱体1米处)物理特性净重(Kg)297毛重(Kg)337尺寸(W×D×H)mm725×430×1180执行标准YD/T1095-2008蓄电池★后备延时时间(满载)≥2小时有效容量开始使用100%使用1~2年90%使用4年后70~80%自放电速率25℃存放12个月,容量>60% 深充深放循环次数100%,≥180次可存放时间>4个月深度放电保护具备电池状态检测具备电池放电实时监测及显示具备充电时间8小时之内充到电池容量的90%电池保护具备厂商项目授权书、质保承诺函要求提供厂家设备服务承诺书原件(承诺本项目的整套设备的质保期为三年免费);要求提供针对本项目的厂家授权书原件。

GM500-GGEMINI SERIESEndless power through redundancy500+500W 24hour fully continuous power outputPS2 mini redundant power with 150mm(W) x 85mm(H) x 180mm(D)80 PLUS Gold Certified Active PFC (full range)1+1 redundant configurationHot swappable designConvenient pull-out handle barsIndustry-leading reliabilitySupport PMBus 1.2The following manual and guides were carefully prepared by the SilverStone engineering team to help you maximize the potential of your SilverStone product. Please keep this manual for future reference when upgrading or performing maintenance on your system. A copy of this manual can also be downloaded from our website at:Installation and system optimization guide:SpecificationGeneralAC input specificationsDC output specification ProtectionEnvironmental requirements Agency requirements Redundant power supply function PMBusReliabilityPhysical characteristics size P.1 P.1 P.1 P.2 P.5 P.6 P.6 P.7 P.8 P.12 P.12SPECIFICATIONSilverStone GEMINIGM500-GMini Redundant Switching Power Supply80 PLUS Gold PMBus 1.2500W+500W01This is the specification of Model GM500-G; it is intended to describe the functions and performance of the mini redundant power supply. The GM500-G 500 watts mini redundant power supply is featured with Active PFC (Power Factor Correction) capability and gold efficiency for 80+ and PMBus function meets IEC61000-3-2 and equips full range Input features.The power supply must meets inrush requirements of any rated AC voltage, during turn on at any phase of voltage, during a single cycle AC dropout condition, during repetitive On/Off cycling of AC, and over the specified temperature range. The peak inrush current shall be 30/60A @ 115/230 VAC (25 ) per module when cold start and less than the rating of its critical components (including input fuse, bulk rectifiers, and surge limiting device).The power supply must operate within all specified limits over the input voltage range in Table 1.Harmonics distortion of up to 10% THD must not cause the power supply to go out of specified limits.Base on the minimum voltage and power transfer, the max current calculation as below:Table 1 – AC Input Voltage and FrequencyMax Current (Watt / Efficiency) / Minimum Voltage2.2 AC inrush current2.1 AC input voltage, frequency and current (Rating: 100V-240 VAC, 47-63Hz, 8-4A)1. General2. AC input specificationsParameter Voltage (115V)Voltage (230V)FrequencyMinimum 90 VAC 180 VAC 47 HzNormal 100-120 VAC 200-240 VAC 50 / 60 HzMaximum 132 VAC 264 VAC 63 HzMax. Current8A 4A N/A022.3 Input power factor correction (Active PFC)The power factor at 50% load shall be 0.9 at 230V input voltage.2.4 Input current harmonicsWhen the power supply is operated in 90-264 VAC of Sec. 2.1, the input harmonic current drawn on the power line shall not exceed the limits set by IEC61000-3-2 Class A and GB17625.1 standards. The power supply shall incorporate universal power input with active power factor correction.2.5 DropoutAn AC line dropout of 17mS or less shall not cause any tripping of control signals or protection circuits. If the AC dropout lasts longer than 17mS, the power supply should recover and meet all turn on requirements. The power supply shall meet the regulation requirement over all rated AC voltages, frequencies, and output loading conditions. Any dropout of the AC line shall not cause damage to the power supply. An AC line dropout is defined as a drop in AC line to 0 VAC at any phase of the AC line for any length of time.3.1 Output current / loading3.2 DC voltage regulation, ripple and noiseThe following table defines power and current rating. The power supply shall meet both static and dynamic voltage regulation requirements for minimum load condition.The power supply output voltages must stay within the following voltage limits when operating at steady state and dynamic loading conditions. All outputs are measured with reference to the return remote sense (Returns) signal. The +5V, +3.3V, +12V, -12V and +5VSB outputs are measure at the power supply connectors references to Returns. The +5V and +3.3V is measured at its remote sense signal (+5VS, +3.3VS) located at the signal connector.Table 2– Output Loads Range 1Note 1: Maximum continuous total DC output power should not exceed 550W.3. DC output specificationOutput Voltage Max. Load Min. Load Max. Combined T otal Output+5V 25A 1A170W500W+3.3V 25A 1A+12V 41A 1A --12V 0.8A 0A -+5VSB 3.5A 0.1A 17.5WTable 3 – Regulation, ripple and noiseOutput Voltage Load Reg.Line Reg.Ripple & Noise+5V +/-5 +/-1 50mV+3.3V +/-5 +/-1 50mV+12V +/-5 +/-1 120mV-12V +/-5 +/-1 120mV+5VSB +/-5 +/-1 50mV03These are the timing requirements for the power assembly operation. The output voltages must rise from 10% to within regulation limits (Tvout_rise) within 5 to 70mS. The +5V, +3.3V and +12V output voltages should start to rise at about the same time. All outputs must rise monotonically. The +5V output must occur first than the +3.3V output during any point of the voltage rise. The +5V output must never be greater than the +3.3V output by more than 2.25V. Each output voltage shall reach regulation within 50 ms (Tvout_on) of each other during turn on of the power supply. Each output voltage shall fall out of regulation within 400 mS (Tvout_off) of each other during turn off. Figure 1 and figure 2 shows the turn on and turn off timing requirement. In Figure 2, the timing is shown with both AC and PSON# controlling the on/off of the power supply.Ripple and Noise shall be measured using the following methods:a) Measurements made differentially to eliminate common-mode noise.b) Ground lead length of oscilloscope probe shall be 0.25 inch.c) Measurements made where the cable connectors attach to the load.d) Outputs bypassed at the point of measurement with a parallel combination of 10uF tantalum capacitor in parallel with a 0.1uF ceramic capacitors.e) Oscilloscope bandwidth of 0 Hz to 20MHz.f) Measurements measured at locations where remote sense wires are connected.g) Regulation tolerance shall include temperature change, warm up drift and dynamic load.3.3 Timing requirementsTable 4 – Output Voltage TimingItem Tvout_riseTvout_on Tvout_offDescription Output voltage rise time from each main output.(+5Vsb < 70mS)All main output must be within regulation of each other within this time.All main output must leave regulation within this timeMIN 5N/A N/AMAX 7050400Units mS mS mSFigure 1:Output Voltage Timing043.4 Remote On/Off Control: PSON#The PSON# signal is required to remotely turn on/off the power supply. PSON# is an active low signal that turns on the +5V, +3.3V, +12V,-5V and –12V power rails. When this signal is not pulled low by the system, or left open, the outputs (except the +5VSB and V bias) turn off. This signal is pulled to a standby voltage by a pull-up resistor internal to the power supply.Table 5 – Turn On/Off TimingItemT sb_on-delayT ac_on-delay Tvout_holdup Tpwok_holdup Tpson_on_delay Tpson_pwok Tpwok_on Tpwok_off Tpwok_low T sb_vout MIN N/AN/A 18175N/A 100110050MAX 15002500N/A N/A 40050500N/A N/A 1000Units mSmSmSmSmSmSmSmSmSmSDescriptionDelay from AC being applied to +5VSB is being within regulation.Delay from AC being applied to all output voltages being Within regulation.All main output voltage stay within regulation after loss of ACDelay from loss of AC deassertion of PWOK.Delay from PSON# active to output voltage within regulation limits.Delay from PSON# deactive to PWOK being deasserted.Delay from output voltage within regulation limits to PWOK asserted at turn on.Delay from PWOK deasserted to output voltages (+5V , +3.3V , +12V) dropping out of regulation limits.Duration of PWOK being in the deasserted state during an off/on cycle using AC or the PSON# signal.Delay from +5VSB being in regulation to O/Ps being in regulation at AC turn on.Table 6 – PWOK Signal CharacteristicSignal TypePSON# = Low PSON# = HighAccepts an open collector/drain input from the system. Pull-up to VSB located in power supply.Power ON Power OFF05The efficiency should be measured module at 230 VAC and with external fan power source at specified loading.3.5 Efficiency (80+ Gold)The +5VSB output is always on (+5V Standby) when AC power is applied and power switch is turned on. The +5VSB line is capable of delivering at a maximum of 3.5A for PC board circuit to operate.3.6 +5VSB (Standby)The OPP function shall work at 110%~160% of rating of output power, then all outputs shut down in a latch off mode. The latch shall be cleared by toggling the PSON# signal or by cycling the AC power. The power supply shall not be damaged from repeated power cycling in this condition. If only one module works inside the power supply, the OPP is at 110%~160% of rating of power supply.4.1 Over power protectionEach hot swap module has respective OVP circuit. Once any power supply module shut down in a latch off mode while the output voltage exceeds the over voltage limit shown in Table 7, the other modules should deliver the sufficient power to the device continually.4.2 Over voltage protectionInput Voltage 230 VAC20% Load 88%50% Load 92%100% Load88%Reference all test conditions.Voltage +5V +3.3V +12V 5VSBMinimum +5.7V +3.9V +13.3V +5.7VMaximum +6.5V +4.5V +14.5V +6.5VShutdown ModeLatch Off Latch Off Latch Off Auto recoveryTable 7 –Over Voltage protectionProtection circuits inside the power supply shall cause only the power supply’s main outputs to shutdown. If the power supply latches off due to a protection circuit tripping, either an AC cycle OFF for 15 sec or PSON #cycle HIGH for 1 sec must be able to restart the power supply.4. Protection064.3 Over current protectionThe power supply should contain the OCP function on each hot swap module. The power supply should be shut down in a latch off mode while the respective output current exceeds the limit as shown in Table 8. When the latch has been cleared by toggling the PSON# single or cycling the AC input power. The power supply module should not be damaged in this condition.4.4 Short circuit protection5.1 Temperature5.2 Humidity6.1 Safety (Planning)6.2 AC Input leakage currentThe power supply shall shut down in a latch off mode when the output voltage is short circuit.Input leakage current from line to ground will be less than 3.5mA rms. Measurement will be made at 240 VAC and 60Hz.Operating T emperature Range:Non-Operating T emperature Range:0°C ~ 40°C -20°C ~ 70°CVoltage +5V +3.3V +12VMinimum 110%110%110%Maximum 160%160%160%Shutdown ModeLatch Off Latch Off Latch OffTable 8 –Over Current protection5. Environmental requirements6. Agency requirementsOperating Humidity Range:Non-Operating Humidity Range:20% ~ 90%RH non-condensing 5% ~ 95%RH non-condensingProduct Safety:UL60950-1/CSA 60950 (USA/Canada)TÜV (CB) IEC60950 (report to include all country national deviations)EN60950-1(Europe)/IEC60950-1(International)FCC(USA)CE-low voltage directive 2006/95/EC(Europe)7. Redundant power supply function7.1 RedundancyThe redundant power supply is N+1=N (500W+500W=500W) function power supply, each one module is redundancy when any one module was failed. To be redundant each item must be in the hot swap power supply module.7.2 Hot swap requirementsThe redundant power supply modules shall be hot swappable. Hot swapping a power supply is the process of inserting and extracting a power supply from an operating. During this process the output voltage shall remain within the limits specified in Table 7 with the capacitive load specified Table 9. The Sub-system shall not exceed the maximum inrush current as specified in section 2.2. The power supply can be hot swapped by the following methods:AC connects with each module. Up to two power supplies may be on a single AC power source. Extraction: The AC power will be disconnected from the power supply first and then the power supply is extracted from the sub-system. This could occur in standby mode or powered on mode. Insertion: The module is inserted into the cage and then AC power will be connected to the power supply module.For power modules with AC docking at the same time as DC. Extraction: The module is extracted from the cage and both AC and DC disconnect at the same Time. This could occur in standby or power on mode. No damage or arcing shall occur to the DC or AC contacts which could cause damage. Insertion: The AC and DC connect at the same time as the module is inserted into the cage. No damage to the connector contacts shall occur. The module may power on or come up into standby mode.Many variations of the above are possible. Supplies need to be compatible with these different variations depending upon the sub-system construction. In general, a failed (off by internal latch or external control) supply may be removed, then replaced with a good power supply (must use the same model); however, hot swap needs to work with operational as well as failed power supplies. The newly inserted power supply may get turned on by inserting the supply into the system or by system management recognizing an inserted supply and explicitly turning it on.7.3 LED IndicatorsThere is a single bi-color LED to indicate the power supply status. The Green LED turn ON to indicate that all the power outputs are available. The Orange LED (Green+Red) turn ON to indicate that the power supply has stand-by or failed shutdown due to over current, the Red LED turn ON to indicate the Fan of the power supply has failed. The LED(s) shall be visible on the exterior face of the power supply. The LED location shall meet ESD requirements. LED shall be securely mounted in such a way that incidental pressure on the LED shall not cause displaced.07088.2.1. Power supply management interface address8.1 PMBus communicationThe PMBus serial bus communication devices for I2C data in the power supply shall be compatible with both SMBus 2.0 “high power” and I2C Vdd based power and drive. This bus shall operate at 3.3V but tolerant of 5V signaling. The SMBus pull-ups are located on the motherboard and may be connected to 3.3V or 5V.Two pins are allocated on the power supply. One pin is the serial clock (SMBus_SCL). The second pin is used for serial data (SMBus_SDA). Both pins are bi-directional and are used to form a serial bus.The device(s) in the power supply shall be located at an address(s) determined by addressing pins A0 and A1 on the power supply module. The circuits inside the power supply shall derive their power from the 5VSB bus. Device(s) shall be powered from the system side of the 5VSB device. No pull-up resistors shall be on SCL or SDA inside the power supply. There pull-up resistors should be located external to the power supply.8.2 Power supply management interfaceThe device in the power supply shall derive its power off of the 5VSB output on the system side. It shall be located at an address set by the A0 and A1 pins. Refer to the PMBus specification posted on the website for details on the power supply monitoring interface requirements. I2C is a SMBus interface used to communicate power management information to the system.Device address locationsPDB addressing A1/A0Device AddressHousing--M11/1B6hM20/1B2h8. PMBus8.2.2. PMBus command code summaryPMBus Revison1.2 specification shall be used for the communication with system.Command code19h1Ah88h89h8Bh8Ch8Dh90h91h96h97h98h99h9Ah9Bh9EhA0hA1hA7hB0hD0hD1hD2hD3hD4hD5hCommand NameCAP ABILITYQUERYREAD_ACV_INREAD_ACI_INREAD_VOUTREAD_IOUTREAD_TEMPERA TURE_1READ_FAN1_SPEEDREAD_ FAN2_SPEEDREAD_POUTREAD_PINPMBus_REVISIONMFR_IDMFR_MODELMFR_ REVISIONMFR_SERIALMFR_VIN_MINMFR_VIN_MAXMFR_POUT_MAXUSER_DA T A_00ReservedReservedReservedReservedREAD_AC_PFCREAD_ AC_FREQUENCSMBus Transaction TypeREAD BYTEREAD BYTEREAD WORDREAD WORDREAD WORDREAD WORDREAD WORDREAD WORDREAD WORDREAD WORDREAD WORDREAD BYTER/W BlockR/W BlockR/W BlockR/W BlockREAD WORDREAD WORDREAD WORDREAD BYTE----READ WORDREAD WORDNumber of Data Bytes11222222222116162162221222222(Data Byte Type ASCII Code or HEX Code)09MFR-ManufacturerCommand code19h1Ah88h89h8Bh8Ch8Dh90h91h96h97h98h99h9Ah9Bh9EhA0hA1hA7hB0hD0hD1hD2hD3hD4hD5hCommand NameCAP ABILITYQUERYREAD_ACV_INREAD_ACI_INREAD_VOUTREAD_IOUTREAD_TEMPERA TURE_1READ_FAN_SPEED_1READ_ FAN_SPEED_2READ_POUTREAD_PINPMBus_REVISIONMFR_IDMFR_MODELMFR_ REVISIONMFR_SERIAL_NO.MFR_VIN_MINMFR_VIN_MAXMFR_POUT_MAXUSER_DA T A_00ReservedReservedReservedReservedREAD_AC_PFCREAD_ AC_FREQUENCMeaning--239.88 V2.499 A12.100 V24.000 A38.512400 rpmReserved250.00 W500.0 W1SilverStoneSST-GM500-GA0201312120001100 V AC240 V AC500WStatus Byte----0.999960.0HZV ALUE ( ASCII or HEX CODE )00HF8H5DH,B4H09H,C3H2FH,44H5DH,C0H01H,81H30H,70H00H,00H61H,A8H17H,70H01H4BH,49H,4EH,54H,52H,4FH,4EH,20H,20H,20H,20H,20H,20H,20H,20H,20H4DH,56H,50H,2DH,36H, 30H,30H,56H,50H,50H, 20H,20H,20H,20H41H,30H32H,30H,31H,33H,31H,32H,31H,32H,30H,30H,30H,31H,20H,20H,20H,20H00H,64H00H,F0H02H,58H00H----27H,0FH02H,58H(Data Byte Type ASCII Code or HEX Code)1011Command code= B0h Command Name (USER_DATA_00)8.2.3. PMBus Command Protocol8.2.4. PMBus signal connectorBit Number76543210Status Bit Name Reserved Reserved Reserved Reserved Reserved Reserved PS_ON_Status AC_Status (Must have12V)Meaning Default=0Default=0Default=0Default=0Default=0Default=0PS_OFF =0,PS_ON =1AC OK =0,AC Fail =1PMBus command protocol for the two steps (Figure 8.2.3-1). The first step is master device sends Device Address and Command Code1 to slave device. The Command Code 1 is set what kind data will receive on master device.The second step is the master device will receive one or more DATA BYTE coming slave device.Figure 8.2.3-19. Reliability9.1 Mean time between failures (MTBF)TThe MTBF of the power supply shall be calculated utilizing the Part-Stress Analysis method of MIL-217F or Bell core RPP. The calculated MTBF of the power supply shall be greater than 100,000 hours under the following conditions:Full rated load120V AC inputGround Benign25°C10. Physical characteristics size10.1 Dimension: 150(W) x 85m(H) x 180(D)12。

DC/DC Converter2BASIC CHARACTERISTICSParameterConditionMin.Typ.Max.Input Voltage Rangenom. V IN = 48VDC 32VDC 48VDC 96VDC Under Voltage Lockout (UVLO)DC-DC ON 29VDC 30VDC 31VDC DC-DC OFF 27VDC 28VDC 29VDC hysteresis 1VDC2VDC 3VDC Input Current V IN = 32VDC 18A 19A Inrush Current 10AQuiescent Current V IN = 48VDC80mA V IN = 72, 80VDC V OUT = 12.4/13.7VDC 40mA V OUT = 24VDC 50mA Standby Current V IN = 48VDC V OUT = 12.4/13.7VDC 6mA V OUT = 24VDC20mA Start-up TimeV IN = 48VDCfrom V IN = Turn-on, threshold to10% V OUT650ms 800ms from CTRL = on to 10% V OUT 250ms400msThe RMOD500-W DC-DC converter is ideally for the use in all off-highway electric vehicles. This family is an extremely robust plug & play module with 500 Watts, which generates the isolated Vout = 12,4 / 13,7 / 24,5VDC low voltage network from the traction battery level. The wide input voltage range 32-96V covers the common 48V and 80V battery voltages in this off-highway segment. Thanks to the waterproof and dust proof housing construction, the devices can directly be connected mechanically and thermally to the chassis (i.e. at any point on the vehicle) and operate reliably even under the most adverse conditions.E224736RoHS 2+compliant 10 from 10REACHcompliantNotes:Note1: Efficiency is tested at nominal input and 100% +25°C ambientmax. Output Power nom. Input VoltageRMOD500-60- SW/Part NumberInput Voltage Range[VDC]nom. Output Voltage[VDC]max. Output Current [A]Efficiency min.(1)[%]RMOD500-60-13.7SW 32-9613.736.589.5 RMOD500-60-13SW/OR 32-961338.589.5RMOD500-60-12.4SW 32-9612.44088.2RMOD500-60-11.7SW/OR 32-9611.742.588.2RMOD500-60-24.5SW 32-9624.52191.5RMOD500-60-23.5SW/OR32-9623.52191.5500 Watt4.53” x 8.0”Single OutputOR (ORing Diode)S inglenom. Output VoltageUL62368-1 certifiedCAN/CSA-C22.2 No. 62368-1 certified EN62368-1 certifiedp re li mi n a ryPROTECTIONSParameterTypeValueInternal Input Fuse 500V/30A Fast-acting fuse Short Circuit Protection (SCP)hiccup mode, automatic recoveryInput Reverse Polarity Protection-96VDCOver Voltage Protection (OVP)RMOD500-60-12.4SW and RMOD500-60-11.7SW/OR17VDC typ., hiccup mode, auto recovery RMOD500-60-13.7SW and RMOD500-60-13SW/OR 17-19VDC, hiccup mode, auto recoveryRMOD500-60-24.5SW and RMOD500-60-23.5SW/OR28-30VDC, hiccup mode, auto recoveryOver Current Protection (OCP)RMOD500-60-12.4SW and RMOD500-60-11.7SW/OR50A, hiccup modeRMOD500-60-13.7SW and RMOD500-60-13SW/OR 39-51A, hiccup mode RMOD500-60-24.5SW and RMOD500-60-23.5SW/OR23-27A, hiccup modeOver Voltage Categoryaccording to UL62368-1OVCIOver Temperature Protection (OTP) (3)measured on NTC 118°C typ., automatic restartIsolation Voltage (4)I/P to O/P; I/P to case2250VDC O/P to case 550VDCIsolation Resistance I/P to O/P 10M Ω min.Isolation CapacitanceI/P to O/P 5000pF typ.Notes:Note3: If the temperature exceeds the preset temperature threshold the module will shut down Note4: For repeat Hi-Pot testing, reduce the time and/or the test voltagen a ry-40-30-20020401006070-101030508090809010060705040302010O u t p u t C u r r e n t [%]Ambient Temperature [°C]SAFETY AND CERTIFICATIONSAudio/Video, information and communication technology equipment - Part1: Safety requirements E224736-A6023-ULUL62368-1:2014CAN/CSA-C22.2 NO. 62368-1:2014EN62368-1:2014 + A11:2017RoHS2ROHS-2011/65/EU + AM-2015/863ENVIRONMENTAL (RAILWAY STANDARDS)ParameterConditionValueTemperature ShockTemperature range:-40~125°C Thermal rate: 20°C/min Dwell time : 60mins Total cycle: 300cyclesISO 16750-4VibrationSine wave1.Frequency ( Hz ) amplitude acceleration 5 – 9 HZ ±15 mm 15-200 HZ 10G2. Sweep rate 1 Oct / min.3. Duration 50 Cycles.IEC 60068-2-6:Sine-wave vibration, test FcSubmersion testTotal cycles : 10Dwell time at Tmax : 1h Transition duration : <20s Test-fluid: De-ionized water,5% NaClWater Temperature:<4°C Immersion Time : 5 mins ISO 16750-4Mechanical Shock 50G/11ms 3Shocks for each direction IEC 60068-2-27: Shock, half sine, test EaSalt SprayOperating /no load1. Salt Spray Concentration:5%;2. Test Temperature:35°C;3. Volume of spray:1~2ml/hour/80cm2;4. PH:6.5~7.2;5. Test Time:96hours6. Tolerance: Salt Spray Concentration (±1%); Test Temperature: ± 2°C;IEC 60068-2-11:Test KaDerating Graph (5)(@ Chamber and natural convection 0.1m/s)Notes:Note5: Mount the device on a sufficient heatsink, the baseplate temperature should never exceed 90°C.p re li mi n a ryParameterConditionValueBump 40G/6ms 1000 Shocks for each directionIEC 60068-2-29: Bump, test EbEmission 30-1000MHz 34-45dBuV/m EN12895-2015Immunity 20V/m /27-1000MHz AM; 3V/m /1-2GHz AM; 1V/m /2-2.7GHz AM EN12895-2015,EN61000-4-3ESDDirect: ±8KV; Air: ±15KV EN12895-2015,EN61000-4-2PACKAGING INFORMATIONParameterType ValuePackaging Dimension (LxWxH)cardboard box 500.0 x 300.0 x 200.0mmPackaging Quantity 6pcsStorage Temperature Range-40°C to +105°CThe product information and specifications may be subject to changes even without prior written notice.The product has been designed for various applications; its suitability lies in the responsibility of each customer. The products are not authorized for use in safety-critical applications without RECOM’s explicit written consent. A safety-critical application is an application where a failure may reasonably be expected to endanger or cause p re li mi n。

第一章目录第一章:概述第二章:安装1.安装环境检查及通风和防尘要求2.交流容量及连线要求3.直流容量及连线要求4.电池连线要求5.接地6.其它电缆连线7.调试第三章:电源系统第四章:控制系统第五章:交直流配电第六章:操作第七章:机械性能第二章概述一.简介随着通讯技术的发展,新型通讯设备的迭出,对通讯电源提出了更高的要求。

DUM-48/50B智能开关通信电源是采用新型元器件设计、生产的新一代高频开关电源。

具有容量大、可靠性高、智能化程度高、电网适应范围宽、维护方便等特点。

适用于邮电通信、移动通信基站、水利电力、公安、铁路、计算中心等需要大功率直流电源的场所。

二.系统特点1.DUM-48/50B智能开关通信电源交流输入电压适应范围宽:三相供电266V~494V2.DUM-48/50B智能开关电源整流器交流输入为三相无零线供电方式,彻底解决零线电流问题。

3.整流器具有缺相检测、保护电路。

可以保证在有一相相电压失效的情况下(例如:一相断路),整流器仍能在一定范围内正常工作。

整流器的输出电流不超过25A,整流器不受输入端缺相的影响,继续工作。

倘若,因为整流器输出端负载的变化,一旦输出电流超过了25A,此时整流器输出电流会自动限流于25A处。

4.DUM-48/50B智能开关通信电源整流器采用无源功率因数校正技术,功率因数≥0.92。

5.整流器逆变整流部分采用先进可靠的全桥PWM相移谐振ZVZCS拓扑结构, 与其他拓扑结构相比,它有效地提高了整流器的效率(达到91%以上)。

6.DUM-48/50B智能开关通信电源采用民主均流技术,提高了系统可靠性,减少了设备日常维护工作。

7.DUM-48/50B智能开关通信电源采用微机控制、汉字显示、键盘操作,极大地方便了用户掌握使用。

实现了系统的自动测试、自动诊断、自动控制,又可实现系统的遥信、遥测和遥控。

8.系统控制器对设置的参数具有掉电保护功能。

9.整流器采用智能风冷技术,当整流器温升到启动值时,风扇自动开启,大大提高了风扇使用寿命。

DM-500全数字式交流伺服系统安装操作手册南京华兴数控技术有限公司目录第一章安全警告 (1)1.1与安全有关的符号说明 (1)1.2产品的警告标识 (1)1.3警告标志的内容 (1)1.4安全注意事项 (2)第二章概述 (5)2.1产品简介 (5)2.2运行模式简介 (5)第三章订货信息 (6)3.1驱动器规格 (6)3.2隔离变压器规格 (9)第四章安装 (10)4.1货到检查 (10)4.2安装环境 (10)4.2.1 防护要求 (10)4.2.2 温度要求 (10)4.2.3 振动和冲击 (10)4.3伺服驱动器安装 (11)4.4伺服电机安装 (13)第五章接线 (14)5.1标准接线 (14)5.2信号与功能 (23)5.2.1 端子配置 (23)5.2.2 电源端子TB (23)5.2.3 控制信号输入/输出端子CN2 (24)5.2.4 反馈信号端子CN1 (26)5.3接口电路 (27)5.3.1 开关量输入接口 (27)5.3.2 开关量输出接口 (27)5.3.3 脉冲量输入接口 (27)5.3.4 伺服电机光电编码器输入接口 (28)第六章操作与显示 (29)6.1键盘操作 (29)6.2参数设置(PA-) (29)6.3参数监视(DP-) (30)6.4参数管理(EE-) (31)6.5速度试运行(SR-) (32)6.6点动运行(JR-) (32)第七章参数 (33)7.1参数简介 (33)7.2参数功能 (34)7.3驱动器更换配套伺服电机 (38)7.4伺服驱动器参数调试 (39)7.5驱动器故障解决 (42)第八章运行调整 (45)8.1电源接线 (45)8.2通电测试 (46)8.3调整 (47)8.3.1 基本增益 (47)8.3.2 电子齿轮的设置 (48)8.3.4 启停特性调整 (48)第九章故障诊断 (50)9.1保护诊断功能 (50)9.2故障分析 (51)第十章保养与维护 (54)10.1日常检查 (54)10.2定期检查 (54)10.3部件替换指南 (54)第一章安全警告感谢您选用DM-500交流伺服系统。