(完整版)数字电路基础知识外文翻译毕业设计论文

- 格式:doc

- 大小:35.00 KB

- 文档页数:5

可编辑修改精选全文完整版电力系统电力系统介绍随着电力工业的增加,与用于生成和处置现今大规模电能消费的电力生产、传输、分派系统相关的经济、工程问题也随之增多。

这些系统组成了一个完整的电力系统。

应该着重提到的是生成电能的工业,它不同凡响的地方在于其产品应按顾客要求即需即用。

生成电的能源以煤、石油,或水库和湖泊中水的形式贮存起来,以备以后所有需。

但这并非会降低用户对发电机容量的需求。

显然,对电力系统而言服务的持续性相当重要。

没有哪一种服务能完全幸免可能显现的失误,而系统的本钱明显依托于其稳固性。

因此,必需在稳固性与本钱之间找到平稳点,而最终的选择应是负载大小、特点、可能显现中断的缘故、用户要求等的综合表现。

但是,网络靠得住性的增加是通过应用必然数量的生成单元和在发电站港湾各分区间和在国内、国际电网传输线路中利用自动断路器得以实现的。

事实上大型系统包括众多的发电站和由高容量传输线路连接的负载。

如此,在不中断整体服务的前提下能够停止单个发电单元或一套输电线路的运作。

现此生成和传输电力最普遍的系统是三相系统。

相关于其他交流系统而言,它具有简便、节能的优势。

尤其是在特定导体间电压、传输功率、传输距离和线耗的情形下,三相系统所需铜或铝仅为单相系统的75%。

三相系统另一个重要优势是三相电机比单相电机效率更高。

大规模电力生产的能源有:1.从常规燃料(煤、石油或天然气)、城市废料燃烧或核燃料应用中取得的蒸汽;2.水;3.石油中的柴油动力。

其他可能的能源有太阳能、风能、潮汐能等,但没有一种超越了试点发电站时期。

在大型蒸汽发电站中,蒸汽中的热能通过涡轮轮转换为功。

涡轮必需包括安装在轴承上并封锁于汽缸中的轴或转子。

转子由汽缸周围喷嘴喷射出的蒸汽流带动而平稳地转动。

蒸汽流撞击轴上的叶片。

中央电站采纳冷凝涡轮,即蒸汽在离开涡轮后会通过一冷凝器。

冷凝器通过其导管中大量冷水的循环来达到冷凝的成效,从而提高蒸汽的膨胀率、后继效率及涡轮的输出功率。

原文:Digital circuit definition:Completes with the digital signal to the digital quantity carries onthe arithmetic operation and the logic operation electric circuit iscalled the digital circuit, or number system. Because it has the logicoperation and the logical processing function, therefore calls thenumeral logic circuit.Numeral logic circuit classification (according to function minute):1st, combinatory logic electric circuitThe abbreviation combination circuit, it becomes by the mostbasic logical gate electric circuit combination. The characteristicis: Output value only and then input value related, namely output onlyby then input value decision. The electric circuit has not rememberedthe function, the output condition changes along with the inputcondition change, is similar to the resistance electric circuit, likethe accumulator, the decoder, the encoder, the data selector and so onall belong to this kind.2nd, succession logic circuitThe abbreviation sequence circuit, it is adds on the feedbacklogic return route by the most basic logical gate electric circuit (tooutput the electric circuit which input) or the component combinationbecomes, lies in the sequence circuit with the combination circuitessence difference to have the memory function. The sequence circuitcharacteristic is: The output not only was decided by then inputvalue, moreover also the and circuit past condition concerned. It issimilar to containing the stored energy part the inductance or theelectric capacity electric circuit, like electric circuit and so ontrigger, latch, counter, shift register, reservoir all is the sequencecircuit typical component.Digital circuit characteristic:1st, simultaneously has the arithmetic operation and the logicoperation functionThe digital circuit is take the binary system logic algebra asmathematics foundation, the use binary numeral signal, both can carryon the arithmetic operation and to be able conveniently to carry onthe logic operation (with, or, non-, judgement, comparison, processingand so on), therefore extremely suits to application and so onoperation, comparison, memory, transmission, control,decision-making.2nd, realization simple, the system is reliableBy binary system underlie numeral logic circuit, simplereliable, the accuracy is high.3rd, integration rate high, the function realization is easyIntegration rate high, volume small, the power loss is low isone of digital circuit prominent merits. Electric circuit design,service, maintenance nimble convenient, along with the integratedcircuit technology high speed development, the numeral logic circuitintegration rate is more and more high, integrated circuit blockfunction along with small scale integration electric circuit (SSI),center scale integrated circuit (MSI), large scale integrated circuit(LSI), ultra large scale integrated circuit (VLSI) the developmentalso from the part level, the component level, the part level, theboard card level rises to the system level. The electric circuitdesign composition only must use some standards the integrated circuitblock unit connection to become. Also may use the programmableforeword logic array electric circuit regarding the non- standardspecial electric circuit, through programming method realization freelogic function.Digital circuit application:Digital circuit and numeral electronic technology widespreadapplication to science and technology each domain and so ontelevision, radar, correspondence, electronic accounting machine,automatic control, astronautics.数字电路定义:用数字信号完成对数字量进行算术运算和逻辑运算的电路称为数字电路,或数字系统。

Single-chip1.The definition of a single-chipSingle-chip is an integrated on a single chip a complete computer system .Even though most of his features in a small chip,but it has a need to complete the majority of computer components:CPU,memory,internal and external bus system,most will have the Core.At the same time,such as integrated communication interfaces,timers,real-time clock and other peripheral equipment.And now the most powerful single-chip microcomputer system can even voice ,image,networking,input and output complex system integration on a single chip.Also known as single-chip MCU(Microcontroller),because it was first used in the field of industrial control.Only by the single-chip CPU chip developed from the dedicated processor. The design concept is the first by a large numberof peripherals and CPU in a single chip,the computer system so that smaller,more easily integrated into the complex and demanding on the volume control devices.INTEL the Z80 is one of the first design in accordance with the idea of the processor,From then on,the MCU and the development of a dedicated processor parted ways.Early single-chip 8-bit or all the four.One of the most successful is INTELs 8031,because the performance of a simple and reliable access to a lot of good praise.Since then in 8031to develop a single-chip microcomputer system MCS51 series.based on single-chip microcomputer system of the system is still widely used until now.As the field of industrial control requirements increase in the beginning of a 16-bit single-chip,but not ideal because the price has not been very widely used.After the90s with the big consumer electronics product development,single-chip technology is a huge improvement.INTEL i960 series with subsequent ARM in particular ,a broad range of application,quickly replaced by 32-bit single-chip 16-bit single-chip performance has been the rapid increase in processing power compared to the 80s to raise a few hundred times.At present,the high-end 32-bit single-chip frequency over 300MHz,the performance of the mid-90s close on the heels of a special processor,while the ordinary price of the model dropped to one U.S dollars,the most high-end models,only 10 U.S dollars.Contemporary single-chip microcomputer system is no longer only the bare-metal environment in the development and use of a large number of dedicated embedded operating system is widely used in the full range of single-chip microcomputer.In PDAs and cellphones as the coreprocessing of high-end single-chip or even a dedicated direct access to Windows and Linux operating systems.More than a dedicated single-chip processor suitable for embedded systems,so it was up to the application.In fact the number of single-chip is the worlds largest computer.Modern human life used in almost every piece of electronic and mechanical products will have a single-chip integration.Phone,telephone,calculator,home applicances,electronic toys,handheld computers and computer accessories such as a mouse in the Department are equipped with 1-2 single chip.And personal computers also have a large number of single-chip microcomputer in the workplace.Vehicles equipped with more than 40 Department of the general single-chip ,complex industrial control systems and even single-chip may have hundreds of work at the same time!SCM is not only far exceeds the number of PC and other integrated computing,even more than the number of human beings.2.single-chip introducedSingle-chip,also known as single-chip microcontroller,it is not the completion of a logic function of the chip,but a computer system integrated into a chip.Speaking in general terms: a single chip has become a computer .Its small size,light weight,cheap,for the learning,application and development of facilities provided .At the same time,learning to use the principle of single-chip computer to understand and structure the best choice.Single-chip and computer use is also similar to the module,such as CPU,memory,parallel bus, as well as the role and the same hard memory,is it different from the performance of these components are relatively weak in our home computer a lot,but the price is low ,there is generally no more than 10yuan,,can use it to make some control for a class of electrical work is not very complex is sufficient.We are using automatic drum washing machines, smoke hood,VCD and so on inside the home appliances can see its shadow! It is mainly as part of the core components of the control.It is an online real-time control computer,control-line is at the scene,we need to have a stronger anti-interference ability,low cost,and this is off-line computer(such as home PC)The main difference.By single-chip process,and can be amended.Through different procedures to achieve different functions,in particular the special unique features,this is the need to charge other devices can do a great effort,some of it is also difficult to make great efforts to do so .A function is not very complicated fi the United States the development of the 50s series of 74 or 60 during the CD4000series to get these pure hardware,the circuit must be a big PCB board !However,if the United States if the successful 70s seriesof single-chip market ,the result will be different!Simply because the adoption of single-chip preparation process you can achieve high intelligence,high efficiency and high reliability!Because of cost of single-chip is sensitive,so the dominant software or the lowest level assembly language,which is in addition to the lowest level for more than binary machine code of the language ,since such a low-level so why should we use ?Many of the seniors language has reached a level of visual programming why is it not in use ?The reason is simple ,that is,single-chip computer as there is no home of CPU,also not as hard as the mass storage device.A visualization of small high-level language program,even if there is only one button which will reach the size of dozens of K! For the home PCs hard drive is nothing,but in terms of the single-chip microcomputer is unacceptable.Single-chip in the utilization of hardware resources have to do very high ,so the compilation of the original while still in heavy use .The same token ,if the computer giants operating system and appplications run up to get the home PC,homePCcan not afford to sustain the same.It can be said that the twentieth century across the three “power”of the times,that is ,the electrical era,the electronic age and has now entered the computer age. However ,such a computer,usually refers to a personal computer,or PC.It consisits of the host ,keyboards,displays .And other components.There is also a type of computer,not how most people are familiar with . This computer is smart to give a variety of mechanical single-chip(also known as micro-controller).As the name suggests,these computer systems use only the minimum of an integrated circuit to make a simple calculation and control. Because of its small size,are usually charged with possession of machine in the “belly”in. It in the device,like the human mind plays a role, it is wrong,the entire device was paralyzed .Now,this single chip has a very wide field of use,such as smart meters,real-time industrial control,communications equipment,navigation systems,and household appliances. Once a variety of products with the use of the single-chip ,will be able to play so that the effectiveness of product upgrading,product names often adjective before the word “intelligent”,such as was hing machines and so intelligent.At present,some technical personnel of factories or other amateur electrtonics developers from engaging in certain products ,not the circuit is too complex ,that is functional and easy to be too simple imitation.The reason may be the product not on the cards or the use of single-chip programmable logic device on the other.3.single-chip historysingle-chip 70 was born in the late 20th century,experienced a SCM,MCU,SOC three stages.Single-chip micro-computer 1.SCM that(Single Chip Microcomputer)stage,is mainly a single from to find the best of the best embedded systems architecture.”Innovation model”to be successful,lay the SCM with the general-purpose computers,a completely different path of development . In embedded systems to create an independent development path,Intel Corporation credit.That is 2.MCU microcontroller(Micro Controller Unit)stage,the main direction of technology development: expanding to meet the embedded applications,the target system requirements for the various peripheral circuits and interface circuits,to highlingt the target of intelligent control.It covers all areas related with the objectSystem,therefore,the development of MCU inevitably fall on the heavy electrical,electronics manufacturers. From this point of view ,Intels development gradually MCU has its objective factors.MCU in the development ,the most famous manufacturers when the number of Philips Corporation.Philips in embedded applications for its enormous advantages,the MCS-51 from the rapid deveploment of single-chip micro-computer to the microcontroller.Therefore,when we look back at the path of development of embedded systems,Intel and Philips do not forget the historical merits.3.Single-chip is an independent embedded systems development,to the MCU an important factor in the development stage,is seeking applications to maximize the natural trend .With the mico-electronics technology,IC design,EDA tools development,based on the single-chip SOC design application systems will have greater development. Therefore,the understanding of single-chip micro-computer from a single ,monolithic single-chip microcontroller extends to applications.4.Single-chip applicationsAt present,single-chip microcomputer to infiltrate all areas of our lives,which is very difficult to find the area of almost no traces of single-chip microcomputer.Missile navigation equipment,aircraft control on a variety of instruments,compuer network communications and data transmission,industrial automation,real-time process control and data processing ,are widely used in a variety of smart IC card,limousine civilian security systems,video recorders,cameras,the control of automatic washing machines,as well as program-controllde toys,electronic pet,etc,which are inseparable from the single-chip microcomputer.Not to mention the field of robot automation ,intelligent instrumentation,medical equipment has been. Therefore,the single- chip learning ,development and application to a large number of computer applications and intelligent control of scientists,engineers.Single-chip widely used in instruments and meters,household appliances,medical equipment ,acrospace,specialized equipment and the intellingent management in areas such as process control,generally can be divided into the following areas:1.In the smart application of instrumentationSingle-chip with small size,low power consumption,control,and expansion flexibility , miniaturization and ease of sensors,can be realized,suchvoltage,power,frequency,humidity,temperature,flow,speed,thickness,angle,length,hardness,elemen t,measurement of physical pressure. SCM makes use of digital instrumentation,intelligence,miniaturization and functional than the use of electronic or digital circuitry even stronger.For example,precision measurement equipment(power meter,oscilloscope,and analyzer).2.In the industrial controlMCU can constitute a variety of control systems,data acquisition system.Such as factory assembly line of intelligent management ,intelligent control of the lift ,all kinds of alarm systems ,and computer networks constitute a secondary control system.3.In the applicationof household appliancesIt can be said that almost all home appliances are using the single-chip control,electric rice from favorable,washing machines,refrigerators,air conditioners,color TV and other audio video equipment,and then to the electronic weighing equipment,all kinds ,everywhere.4.On computer networks and communication applications in the field ofGenerally with the modern single-chip communication interface,can be easily carried out with computer carried out with computer data communications,computer networks and in inter-application communications equipment to provide an excellent material conditions,the communications equipment to provide an excellent material condition,from the mobile phone ,telephone , mini-program-controlled switchboards,buiding automated communications system call,the train wireless communications,and then you can see day-to-day work of mobile phones,Mobile communications,such as radios.5.Single-chip in the field of medical equipment applicationsSingle-chip microcomputer in medical devices have a wide range of purpose,such as medical ventilator,various analyzers,monitors,ultrasonic diagnostic equipment and hospital call systems.6.In a variety of large-scale electrical applications of modularSome special single-chip design to achieve a specific function to carry out a variety of modular circuitapplications,without requiring users to understand its internal structure.Integrated single-chip microcomputer such as music ,which seems to be simpleFunctions,a miniature electronic chip in a pure(as distinct from the principle of tape machine),would require a complex similar to the principle of the computer. Such as :music signal to digital form stored in memory(similar to ROM),read out by the microcontroller into analog music signal(similar to the sound card).In large circuits,modular applications that greatly reduces the size ,simplifying the circuit and reduce the damage,error rate ,but also to facilitate the replacement.In addition,single-chip microcomputer in the industrial,commercial,financial,scientific research ,education,defense aerospace and other fields have a wide range of uses.单片机1.单片机定义单片机是一种集成在电路芯片上的完整计算机系统。

标准文档外文翻译院(系)专业班级姓名学号指导教师年月日Programmable designed for electro-pneumatic systemscontrollerJohn F.WakerlyThis project deals with the study of electro-pneumatic systems and the programmable controller that provides an effective and easy way to control the sequence of the pneumatic actuators movement and the states of pneumatic system. The project of a specific controller for pneumatic applications join the study of automation design and the control processing of pneumatic systems with the electronic design based on microcontrollers to implement the resources of the controller.1. IntroductionThe automation systems that use electro-pneumatic technology are formed mainly by three kinds of elements: actuators or motors, sensors or buttons and control elements like valves. Nowadays, most of the control elements used to execute the logic of the system were substituted by the Programmable Logic Controller (PLC). Sensors and switches are plugged as inputs and the direct control valves for the actuators are plugged as outputs. An internal program executes all the logic necessary to the sequence of the movements, simulates other components like counter, timer and control the status of the system.With the use of the PLC, the project wins agility, because it is possible to create and simulate the system as many times as needed. Therefore, time can be saved, risk of mistakes reduced and complexity can be increased using the same elements.A conventional PLC, that is possible to find on the market from many companies, offers many resources to control not only pneumatic systems, but all kinds of system that uses electrical components. The PLC can be very versatile and robust to be applied in many kinds of application in the industry or even security system and automation of buildings.Because of those characteristics, in some applications the PLC offers to much resources that are not even used to control the system, electro-pneumatic system is one of this kind of application. The use of PLC, especially for small size systems, can be very expensive for the automation project.An alternative in this case is to create a specific controller that can offer the exactly size and resources that the project needs [3, 4]. This can be made using microcontrollers as the base of this controller.The controller, based on microcontroller, can be very specific and adapted to only one kind of machine or it can work as a generic controller that can be programmed as a usual PLC and work with logic that can be changed. All these characteristics depend on what is needed and how much experience the designer has with developing an electronic circuit and firmware for microcontroller. But the main advantage of design the controller with the microcontroller is that the designer has the total knowledge of his controller, which makes it possible to control the size of the controller, change the complexity and the application of it. It means that the project gets more independence from other companies, but at the same time the responsibility of the control of the system stays at the designer hands2. Electro-pneumatic systemOn automation system one can find three basic components mentioned before, plus a logic circuit that controls the system. An adequate technique is needed to project the logic circuit and integrate all the necessary components to execute the sequence of movements properly.For a simple direct sequence of movement an intuitive method can be used [1, 5], but for indirect or more complex sequences the intuition can generate a very complicated circuit and signal mistakes. It is necessary to use another method that can save time of the project, makea clean circuit, can eliminate occasional signal overlapping and redundant circuits. The presented method is called step-by-step or algorithmic [1, 5], it is valid for pneumatic and electro-pneumatic systems and it was used as a base in this work.The method consists of designing the systems based on standard circuits made for each change on the state of the actuators, these changes are called steps.The first part is to design those kinds of standard circuits for each step, the next task is to link the standard circuits and the last part is to connect the control elements that receive signals from sensors, switches and the previous movements, and give the air or electricity to the supply lines of each step. In Figs. 1 and 2 the standard circuits are drawn for pneumatic and electro-pneumatic system [8]. It is possible to see the relations with the previous and the next steps.3. The method applied inside the controllerThe result of the method presented before is a sequence of movements of the actuator that is well defined by steps. It means that each change on the position of the actuators is a new state of the system and the transition between states is called step.The standard circuit described before helps the designer to define the states of the systems and to define the condition to each change betweenthe states. In the end of the design, the system is defined by a sequencethat never chances and states that have the inputs and the outputs well defined. The inputs are the condition for the transition and the outputs are the result of the transition.All the configuration of those steps stays inside of the microcontroller and is executed the same way it was designed. The sequences of strings are programmed inside the controller with 5 bytes; each string has the configuration of one step of the process. There are two bytes for the inputs, one byte for the outputs and two more for the other configurations and auxiliary functions of the step. After programming, this sequence of strings is saved inside of a non-volatile memory of the microcontroller, so they can be read and executed.The controller task is not to work in the same way as a conventional PLC, but the purpose of it is to be an example of a versatile controller that is design for an specific area. A conventional PLC process the control of the system using a cycle where it makes an image of the inputs, execute all the conditions defined by the configuration programmed inside, and then update the state of the outputs. This controller works in a different way, where it read the configuration of the step, wait the condition of inputs to be satisfied, then update the state or the outputs and after that jump to the next step and start the process again.It can generate some limitations, as the fact that this controller cannot execute, inside the program, movements that must be repeated for some time, but this problem can be solved with some external logic components. Another limitation is that the controller cannot be applied on systems that have no sequence. These limitations are a characteristic of the system that must be analyzed for each application.4. Characteristics of the controllerThe controller is based on the MICROCHIP microcontroller PIC16F877 [6,7] with 40 pins, and it has all the resources needed for thisproject .It has enough pins for all the components, serial communication implemented in circuit, EEPROM memory to save all the configuration of the system and the sequence of steps. For the execution of the main program, it offers complete resources as timers and interruptions.The list of resources of the controller was created to explore all the capacity of the microcontroller to make it as complete as possible. During the step, the program chooses how to use the resources reading the configuration string of the step. This string has two bytes for digital inputs, one used as a mask and the other one used as a value expected. One byte is used to configure the outputs value. One bytes more is used for the internal timer , the analog input or time-out. The EEPROM memory inside is 256 bytes length that is enough to save the string of the steps, with this characteristic it is possible to save between 48 steps (Table 1).The controller (Fig.3) has also a display and some buttons that are used with an interactive menu to program the sequence of steps and other configurations.4.1. Interaction componentsFor the real application the controller must have some elements to interact with the final user and to offer a complete monitoring of the system resources that are available to the designer while creating the logic control of the pneumatic system (Fig.3):•Interactive mode of work; function available on the main program for didactic purposes, the user gives the signal to execute the step. •LCD display, which shows the status of the system, values of inputs, outputs, timer and statistics of the sequence execution.•Beep to give important alerts, stop, start and emergency.• Leds to show power on and others to show the state of inputs and outputs.4.2. SecurityTo make the final application works property, a correct configuration to execute the steps in the right way is needed, but more then that itmust offer solutions in case of bad functioning or problems in the execution of the sequence. The controller offers the possibility to configure two internal virtual circuits that work in parallel to the principal. These two circuits can be used as emergency or reset buttons and can return the system to a certain state at any time [2]. There are two inputs that work with interruption to get an immediate access to these functions. It is possible to configure the position, the buttons and the value of time-out of the system.4.3. User interfaceThe sequence of strings can be programmed using the interface elements of the controller. A Computer interface can also be used to generate the user program easily. With a good documentation the final user can use the interface to configure the strings of bytes that define the steps of the sequence. But it is possible to create a program with visual resources that works as a translator to the user, it changes his work to the values that the controller understands.To implement the communication between the computer interface and the controller a simple protocol with check sum and number of bytes is the minimum requirements to guarantee the integrity of the data.4.4. FirmwareThe main loop works by reading the strings of the steps from the EEPROM memory that has all the information about the steps.In each step, the status of the system is saved on the memory and it is shown on the display too. Depending of the user configuration, it can use the interruption to work with the emergency circuit or time-out to keep the system safety. In Fig.4,a block diagram of micro controller main program is presented.5. Example of electro-pneumatic systemThe system is not a representation of a specific machine, but it is made with some common movements and components found in a real one. The system is composed of four actuators. The actuators A, B and C are double acting and D-single acting. Actuator A advances and stays in specified position till the end of the cycle, it could work fixing an object to the next action for example (Fig. 5) , it is the first step. When A reaches the end position, actuator C starts his work together with B, making as many cycles as possible during the advancing of B. It depends on how fastactuator B is advancing; the speed is regulated by a flowing control valve. It was the second step. B and C are examples of actuators working together, while B pushes an object slowly, C repeats its work for some time.When B reaches the final position, C stops immediately its cycle and comes back to the initial position. The actuator D is a single acting one with spring return and works together with the back of C, it is the third step. D works making very fast forward and backward movement, just one time. Its backward movement is the fourth step. D could be a tool to make a hole on the object.When D reaches the initial position, A and B return too, it is the fifth step.Fig. 6 shows the first part of the designing process where all the movements of each step should be defined [2]. (A+) means that the actuator A moves to the advanced position and (A−) to the initial position. The movements that happen at the same time are joined together in the same step. The system has five steps.These two representations of the system (Figs. 5 and 6) together are enough to describe correctly all the sequence. With them is possible to design the whole control circuit with the necessary logic components. But till this time, it is not a complete system, because it is missing some auxiliary elements that are not included in this draws because they work in parallel with the main sequence.These auxiliary elements give more function to the circuit and are very important to the final application; the most important of them is the parallel circuit linked with all the others steps. That circuit should be able to stop the sequence at any time and change the state of the actuators to a specific position. This kind of circuit can be used as a reset or emergency buttons.The next Figs. 7 and 8 show the result of using the method without the controller. These pictures are the electric diagram of the control circuit of the example, including sensors, buttons and the coils of the electrical valves.The auxiliary elements are included, like the automatic/manual switcher that permit a continuous work and the two start buttons that make the operator of a machine use their two hands to start the process, reducing the risk of accidents.6. Changing the example to a user programIn the previous chapter, the electro-pneumatic circuits were presented, used to begin the study of the requires to control a system that work with steps and must offer all the functional elements to be used in a real application. But, as explained above, using a PLC or this specific controller, the control becomes easier and the complexity can be increasealso.Table 2 shows a resume of the elements that are necessary to control the presented example.With the time diagram, the step sequence and the elements of the system described in Table 2 and Figs. 5 and 6 it is possible to create the configuration of the steps that can be sent to the controller (Tables 3 and 4).While using a conventional PLC, the user should pay attention to the logic of the circuit when drawing the electric diagram on the interface (Figs. 7 and 8), using the programmable controller, described in this work, the user must know only the concept o f the method and program only the configuration of each step.It means that, with a conventional PLC, the user must draw the relationbetween the lines and the draw makes it hard to differentiate the steps of the sequence. Normally, one needs to execute a simulation on the interface to find mistakes on the logicThe new programming allows that the configuration of the steps be separated, like described by the method. The sequence is defined by itself and the steps are described only by the inputs and outputs for each step.The structure of the configuration follows the order:1-byte: features of the step;2-byte: mask for the inputs;3-byte: value expected on the inputs;4-byte: value for the outputs;5-byte: value for the extra function.Table 5 shows how the user program is saved inside the controller, this is the program that describes the control of the example shown before.The sequence can be defined by 25 bytes. These bytes can be dividedin five strings with 5 bytes each that define each step of the sequence (Figs. 9 and 10).7. ConclusionThe controller developed for this work (Fig. 11) shows that it is possible to create a very useful programmable controller based on microcontroller. External memories or external timers were not used in case to explore the resources that the microcontroller offers inside. Outside the microcontroller, there are only components to implement the outputs, inputs, analog input, display for the interface and the serial communication.Using only the internal memory, it is possible to control a pneumatic system that has a sequence with 48 steps if all the resources for all steps are used, but it is possible to reach sixty steps in the case of a simpler system.The programming of the controller does not use PLC languages, but a configuration that is simple and intuitive. With electro-pneumatic system, the programming follows the same technique that was used before to design the system, but here the designer work s directly with the states or steps of the system.With a very simple machine language the designer can define all the configuration of the step using four or five bytes. It depends only on his experience to use all the resources of the controller.The controller task is not to work in the same way as a commercial PLC but the purpose of it is to be an example of a versatile controller that is designed for a specific area. Because of that, it is not possible to say which one works better; the system made with microcontroller is an alternative that works in a simple way.应用于电气系统的可编程序控制器约翰 F.维克里此项目主要是研究电气系统以及简单有效的控制气流发动机的程序和气流系统的状态。

对数字电路的看法英语作文英文回答:Digital circuits have played a pivotal role in shaping the modern world as we know it. They form the backbone of countless electronic devices, from smartphones to supercomputers, enabling them to perform complex calculations, store vast amounts of data, and communicate with each other seamlessly.The advent of digital circuits has revolutionized various industries. In the field of computing, they have made possible the development of powerful computers that can handle intricate tasks such as artificial intelligence, machine learning, and scientific simulations. In the realm of telecommunications, digital circuits have laid the foundation for modern communication systems, enabling us to make phone calls, send text messages, and access the internet at blazing-fast speeds.The beauty of digital circuits lies in their simplicity and reliability. They operate based on a binary system, where all information is represented using only two digits: 0 and 1. This simplicity allows for the design of circuits that are highly accurate and robust, capable of withstanding noise and other disturbances.Moreover, digital circuits are incredibly versatile. They can be configured to perform a wide range of functions, from basic arithmetic operations to complex signal processing and data manipulation. This versatility has made them indispensable in a myriad of applications, from consumer electronics to industrial control systems.As the world continues to embrace digitalization, the demand for digital circuits is only expected to grow. These circuits will continue to drive innovation and shape the future of technology, empowering us to solve complex problems, connect with each other, and unlock new possibilities.中文回答:数字电路的魅力数字电路在塑造我们所知的现代世界中发挥了至关重要的作用。

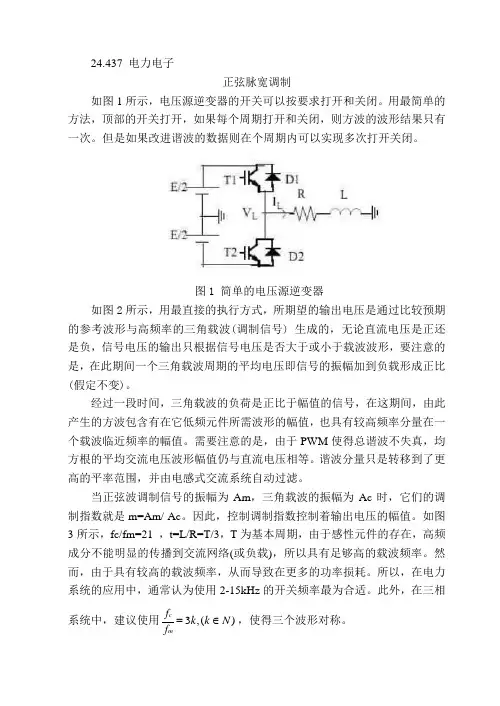

24.437 电力电子正弦脉宽调制如图1所示,电压源逆变器的开关可以按要求打开和关闭。

用最简单的方法,顶部的开关打开,如果每个周期打开和关闭,则方波的波形结果只有一次。

但是如果改进谐波的数据则在个周期内可以实现多次打开关闭。

图1 简单的电压源逆变器 如图2所示,用最直接的执行方式,所期望的输出电压是通过比较预期的参考波形与高频率的三角载波(调制信号) 生成的,无论直流电压是正还是负,信号电压的输出只根据信号电压是否大于或小于载波波形,要注意的是,在此期间一个三角载波周期的平均电压即信号的振幅加到负载形成正比(假定不变)。

经过一段时间,三角载波的负荷是正比于幅值的信号,在这期间,由此产生的方波包含有在它低频元件所需波形的幅值,也具有较高频率分量在一个载波临近频率的幅值。

需要注意的是,由于PWM 使得总谐波不失真,均方根的平均交流电压波形幅值仍与直流电压相等。

谐波分量只是转移到了更高的平率范围,并由电感式交流系统自动过滤。

当正弦波调制信号的振幅为Am ,三角载波的振幅为Ac 时,它们的调制指数就是m=Am/ Ac 。

因此,控制调制指数控制着输出电压的幅值。

如图3所示,fc/fm=21 ,t=L/R=T/3,T 为基本周期,由于感性元件的存在,高频成分不能明显的传播到交流网络(或负载),所以具有足够高的载波频率。

然而,由于具有较高的载波频率,从而导致在更多的功率损耗。

所以,在电力系统的应用中,通常认为使用2-15kHz 的开关频率最为合适。

此外,在三相系统中,建议使用)(,3N k k f f mc ∈=,使得三个波形对称。

图2 主要的脉宽调制图3 SPWM的fc/fm=48,L/R=T/3如图4所示,该过程是比较合适的,因为在该图中有三角载波,其中没有交集的载体作为信号周期。

然而,这种“超调”在一定量的范围内往往是允许获得更大的交流电压,使电压频谱呈现出差异。

需要注意的是,使用一个额外的比率形成一个反周期超过360°的对称波形。

数字电子技术基础,英语作文English: Digital electronic technology is the foundation of modern electronic devices and systems. It involves the use of digital signalsto represent and process information, enabling the creation of complex and versatile electronic devices. Understanding the basics of digital electronic technology is essential for anyone pursuing a career in electronics or related fields. This includes knowledge of binary number systems, Boolean algebra, logic gates, digital circuits, and digital signal processing. With the rapid advancement of technology, digital electronic technology continues to evolve and play a critical role in various industries such as telecommunications, computing, and consumer electronics.中文翻译: 数字电子技术是现代电子设备和系统的基础。

它涉及使用数字信号来表示和处理信息,从而实现复杂多样的电子设备的创建。

了解数字电子技术的基础知识对于任何追求电子学或相关领域职业的人来说至关重要。

优秀论文审核通过未经允许切勿外传Chapter 3 Digital Electronics3.1 IntroductionA circuit that employs a numerical signal in its operation is classified as a digital circuitputers,pocket calculators, digital instruments, and numerical control (NC) equipment are common applications of digital circuits. Practically unlimited quantities of digital information can be processed in short periods of time electronically. With operational speed of prime importance in electronics today,digital circuits are used more frequently.In this chapter, digital circuit applications are discussed.There are many types of digital circuits that electronics, including logic circuits, flip-flop circuits, counting circuits, and many others. The first sections of this unit discuss the number systems that are basic to digital circuit understanding. The remainder of the chapter introduces some of the types of digital circuits and explains Boolean algebra as it is applied to logic circuits.3.2 Digital Number SystemsThe most common number system used today is the decimal system,in which 10 digits are used for counting. The number of digits in the systemis called its base (or radix).The decimal system,therefore,the counting process. The largest digit that can be used in a specific place or location is determined by the base of the system. In the decimal system the first position to the left of the decimal point is called the units place. Any digit from 0 to 9 can be used in this place.When number values greater than 9 are used,they must be expressed with two or more places.The next position to the left of the units place in a decimal system is the tens place.The number 99 is the largest digital value that can be expressed by two places in the decimal system.Each place added to the left extends the number system by a power of 10.Any number can be expressed as a sum of weighted place values.The decimal number 2583,for example, is expressed as (2×1000)+(5×100)+(8×10)+(3×1).The decimal number system is commonly used in our daily lives. Electronically, the binary system.Electronically,the value of 0 can be associated with a low-voltage value or no voltage. The number 1 can then be associated with a voltage value larger than 0. Binary systems that use these voltage values are said to , this chapter.The two operational states of a binary system,1 and 0,are natural circuit conditions. When a circuit is turned off or the off, or 0,state. An electrical circuit that the on,or 1,state. By using transistor or ICs,it is electronically possible to change states in less than a microsecond. Electronic devices make it possible to manipulate millions of 0s and is in a second and thus to process information quickly.The basic principles of numbering used in decimal numbers apply ingeneral to binary numbers.The base of the binary system is 2,meaning that only the digits 0 and 1 are used to express place value. The first place to the left of the binary point,or starting point,represents the units,or is,location. Places to the left of the binary point are the powers of 2.Some of the place values in base 2 are 2º=1,2¹=2,2²=4,2³=8,2⁴=16,25=32,and 26=64.When bases other than 10 are used,the numbers should example.The number 100₂(read“one,zero,zero, base 2”)is equivalent to 4 in base 10,or 410.Starting with the first digit to the left of the binary point,this number this method of conversion a binary number to an equivalent decimal number,write down the binary number first. Starting at the binary point,indicate the decimal equivalent for each binary place location where a 1 is indicated. For each 0 in the binary number leave a blank space or indicate a 0 ' Add the place values and then record the decimal equivalent.The conversion of a decimal number to a binary equivalent is achieved by repetitive steps of division by the number 2.When the quotient is even with no remainder,a 0 is recorded.When the quotient process continues until the quotient is 0.The binary equivalent consists of the remainder values in the order last to first.3.2.2 Binary-coded Decimal (BCD) Number SystemWhen large numbers are indicated by binary numbers,they are difficult to use. For this reason,the Binary-Coded Decimal(BCD) method of counting was devised. In this system four binary digits are used to represent each decimal digit.To illustrate this procedure,the number 105,is converted to a BCD number.In binary numbers,To apply the BCD conversion process,the base 10 number is first divided into digits according to place values.The number 10510 gives the digits 1-0-5.Converting each displayed by this process with only 12 binary numbers. The between each group of digits is important when displaying BCD numbers.The largest digit to be displayed by any group of BCD numbers is 9.Six digits of a number-coding group are not used at all in this system.Because of this, the octal (base 8) and the binary form but usually display them in BCD,octal,or a base 8 system is 7. The place values starting at the left of the octal point are the powers of eight: 80=1,81=8,82=64,83=512,84=4096,and so on.The process of converting an octal number to a decimal number is the same as that used in the binary-to-decimal conversion process. In this method, equivalent decimal is 25810.Converting an octal number to an equivalent binary number is similar to the BCD conversion process. The octal number is first divided into digits according to place value. Each octal digit is then converted into an equivalent binary number using only three digits.Converting a decimal number to an octal number is a process of repetitive division by the number 8.After the quotient determined,the remainder is brought down as the place value.When the quotient is even with no remainder,a 0 is transferred to the place position.The number for converting 409810 to base 8 is 100028.Converting a binary number to an octal number is an importantconversion process of digital circuits. Binary numbers are first processed at a very output circuit then accepts this signal and converts it to an octal signal displayed on a readout device.must first be divided into groups of three,starting at the octal point.Each binary group is then converted into an equivalent octal number.These numbers are then combined,while remaining in their same respective places,to represent the equivalent octal number.3.2.4 Hexadecimal Number SystemThe digital systems to process large number values.The base of this system is 16,which means that the largest number used in a place is 15.Digits used by this system are the numbers 0-9 and the letters A-F. The letters A-P are used to denote the digits 10-15,respectively. The place values to the left of the .The process of changing a proper digital order.The place values,or powers of the base,are then positioned under the respective digits in step 2.In step 3,the value of each digit is recorded. The values in steps 2 and 3 are then multiplied together and added. The sum gives the decimal equivalent value of a . Initially,the converted to a binary number using four digits per group. The binary group is combined to form the equivalent binary number.The conversion of a decimal number to a ,as with other number systems. In this procedure the division is by 16 and remainders can be as large as 15.Converting a binary number to a groups of four digits,starting at the converted to a digital circuit-design applications binary signals arefar superior to those of the octal,decimal,or be processed very easily through electronic circuitry,since they can be represented by two stable states of operation. These states can be easily defined as on or off, 1 or 0,up or down,voltage or no voltage,right or left,or any other two-condition states. There must be no in-between state.The symbols used to define the operational state of a binary system are very important.In positive binary logic,the state of voltage,on,true,or a letter designation (such as A ) is used to denote the operational state 1 .No voltage,off,false,and the letter A are commonly used to denote the 0 condition. A circuit can be set to either state and will remain in that state until it is caused to change conditions.Any electronic device that can be set in one of two operational states or conditions by an outside signal is said to be bistable. Relays,lamps,switches,transistors, diodes and ICs may be used for this purpose. A bistable device .By using many of these devices,it is possible to build an electronic circuit that will make decisions based upon the applied input signals. The output of this circuit is a decision based upon the operational conditions of the input. Since the application of bistable devices in digital circuits makes logical decisions,they are commonly called binary logic circuits.If we were to draw a circuit diagram for such a system,including all the resistors,diodes,transistors and interconnections,we would face an overwhelming task, and an unnecessary one.Anyone who read the circuit diagram would in their mind group the components into standard circuits and think in terms of the" system" functions of the individual gates. Forthis reason,we design and draw digital circuit with standard logic symbols. Three basic circuits of this type are used to make simple logic decisions.These are the AND circuit, OR circuit, and the NOT circuit.Electronic circuits designed to perform logic functions are called gates.This term refers to the capability of a circuit to pass or block specific digital signals.The logic-gate symbols are shown in Fig.3-1.The small circle at the output of NOT gate indicates the inversion of the signal. Mathematically,this action is described as A=.Thus without the small circle,the rectangle would represent an amplifier (or buffer) with a gain of unity.An AND gate the 1 state simultaneously,then there will be a 1 at the output.The AND gate in Fig. 3-1 produces only a 1 out-put when A and B are both 1. Mathematically,this action is described as A·B=C. This expression shows the multiplication operation. An OR gate Fig.3-1 produces a when either or both inputs are l.Mathematically,this action is described as A+B=C. This expression shows OR addition. This gate is used to make logic decisions of whether or not a 1 appears at either input.An IF-THEN type of sentence is often used to describe the basic operation of a logic state.For example,if the inputs applied to an AND gate are all 1,then the output will be 1 .If a 1 is applied to any input of an OR gate,then the output will be 1 .If an input is applied to a NOT gate,then the output will be the opposite or inverse.The logic gate symbols in Fig. 3-1 show only the input and output connections. The actual gates,when wired into a digital circuit, would pin 14 and 7.3.4 Combination Logic GatesWhen a NOT gate is combined with an AND gate or an OR gate,it iscalled a combination logic gate. A NOT-AND gate is called a NAND gate,which is an inverted AND gate. Mathematically the operation of a NAND gate is A·B=. A combination NOT-OR ,or NOR,gate produces a negation of the OR function.Mathematically the operation of a NOR gate is A+B=.A 1 appears at the output only when A is 0 and B is 0.The logic symbols are shown in Fig. 3-3.The bar over C denotes the inversion,or negative function,of the gate.The logic gates discussed .In actual digital electronic applications,solid-state components are ordinarily used to accomplish gate functions.Boolean algebra is a special form of algebra that was designed to show the relationships of logic operations.Thin form of algebra is ideally suited for analysis and design of binary logic systems.Through the use of Boolean algebra,it is possible to write mathematical expressions that describe specific logic functions.Boolean expressions are more meaningful than complex word statements or or elaborate truth tables.The laws that apply to Boolean algebra are used to simplify complex expressions. Through this type of operation it may be possible to reduce the number of logic gates needed to achieve a specific function before the circuits are designed.In Boolean algebra the variables of an equation are assigned by letters of the alphabet.Each variable then exists in states of 1 or 0 according to its condition.The 1,or true state,is normally represented by a single letter such as A,B or C.The opposite state or condition is then described as 0,or false,and is represented by or A’.This is described as NOT A,A negated,or A complemented.Boolean algebra is somewhat different from conventional algebra withrespect to mathematical operations.The Boolean operations are expressed as follows:Multiplication:A AND B,AB,,A·BOR addition:A OR B .A+BNegation,or complementing:NOT A,,A’Assume that a digital logic circuit only C is on by itself or when A,B and C are all on expression describes the desired output. Eight (23) different combinations of A,B,and C exist in this expression because there are three,inputs. Only two of those combinations should cause a signal that will actuate the output. When a variable is not on (0),it is expressed as a negated letter. The original statement is expressed as follows: With A,B,and C on or with A off, B off, and C on ,an output (X)will occur:ABC+C=XA truth table illustrates if this expression is achieved or not.Table 3-1 shows a truth table for this equation. First,ABC is determined by multiplying the three inputs together.A 1 appears only when the A,B,and C inputs are all 1.Next the negated inputs A andB are determined.Then the products of inputs C,A,and B are listed.The next column shows the addition of ABC and C.The output of this equation shows that output 1 is produced only when C is 1 or when ABC is 1.A logic circuit to accomplish this Boolean expression is shown in Fig. 3-4.Initially the equation is analyzed to determine its primary operational function.Step1 shows the original equation.The primary function is addition,since it influences all parts of the equation in some way.Step 2 shows the primary function changed to a logic gate diagram.Step 3 showsthe branch parts of the equation expressed by logic diagram,with AND gates used to combine terms.Step 4 completes the process by connecting all inputs together.The circles at inputs,of the lower AND gate are used to achieve the negative function of these branch parts.The general rules for changing a Boolean equation into a logic circuit diagram are very similar to those outlined.Initially the original equation must be analyzed for its primary mathematical function.This is then changed into a gate diagram that is inputted by branch parts of the equation.Each branch operation is then analyzed and expressed in gate form.The process continues until all branches are completely expressed in diagram formmon inputs are then connected together.3.5 Timing and Storage ElementsDigital electronics involves a number of items that are not classified as gates.Circuits or devices of this type the operation of a system.Included in this system are such things as timing devices,storage elements,counters,decoders,memory,and registers.Truth tables symbols,operational characteristics,and applications of these items will be presented an IC chip. The internal construction of the chip cannot be effectively altered. Operation is controlled by the application of an external signal to the input. As a rule,very little work can be done to control operation other than altering the input signal.The logic circuits in Fig. 3-4 are combinational circuit because the output responds immediately to the inputs and there is no memory. When memory is a part of a logic circuit,the system is called sequential circuit because its output depends on the input plus its an input signal isapplied.A bistable multivibrator,in the strict sense,is a flip-flop. When it is turned on,it assumes a particular operational state. It does not change states until the input is altered.A flip-flop opposite polarity.Two inputs are usually needed to alter the state of a flip-flop. A variety of names are used for the inputs.These vary a great deal between different flip-flops.1. R-S flip-flopsFig.3-5 shows logic circuit construction of an R-S flip-flop. It is constructed from two NAND gates. The output of each NAND provides one of the inputs for the other NAND. R stands for the reset input and S represents the set input.The truth table and logic symbol are shown in Fig. 3-6.Notice that the truth table is somewhat more complex than that of a gate. It shows, for example,the applied input, previous output,and resulting output.To understand the operation of an R-S flip-flop,we must first look at the previous outputs.This is the status of the output before a change is applied to the input. The first four items of the previous outputs are Q=1 and =0. The second four states this case of the input to NANDS is 0 and that is 0,which implies that both inputs to NANDR are 1.By symmetry,the logic circuit will also stable with Q0 and 1.If now R momentarily becomes 0,the output of NANDR,,will rise to resulting in NANDS be realized by a 0 at S.The outputs Q and are unpredictable when the inputs R and S are 0 states.This case is not allowed.Seldom would individual gates be used to construct a flip-flop,rather than one of the special types for the flip-flop packages on a single chipwould be used by a designer.A variety of different flip-flops are used in digital electronic systems today. In general,each flip-flop type R-S-T flip-flop for example .is a triggered R-S flip-flop. It will not change states when the R and S inputs assume a value until a trigger pulse is applied. This would permit a large number of flip-flops to change states all at the same time. Fig. 3-7 shows the logic circuit construction. The truth table and logic symbol are shown in Fig. 3-8. The R and S input are thus active when the signal at the gate input (T) is 1 .Normally,such timing,or synchronizing,signals are distributed throughout a digital system by clock pulses,as shown in Fig. 3-9.The symmetrical clock signal provides two times each period.The circuit can be designed to trigger at the leading or trailing edge of the clock. The logic symbols for edge trigger flip-flops are shown in Fig.3-10.2. J-K flip-flopsAnother very important flip-flop unpredictable output state. The J and K inputs addition to this,J-K flip-flops may employ preset and preclear functions. This is used to establish sequential timing operations. Fig.3-11 shows the logic symbol and truth table of a J-K flip-flop.3. 5. 2 CountersA flip-flop be used in switching operations,and it can count pulses.A series of interconnected flip-flops is generally called a register.Each register can store one binary digit or bit of data. Several flip-flops connected form a counter. Counting is a fundamental digital electronic function.For an electronic circuit to count,a number of things must beachieved. Basically,the circuit must be supplied with some form of data or information that is suitable for processing. Typically,electrical pulses that turn on and off are applied to the input of a counter. These pulses must initiate a state change in the circuit when they are received. The circuit must also be able to recognize where it is in counting sequence at any particular time. This requires some form of memory. The counter must also be able to respond to the next number in the sequence. In digital electronic systems flip-flops are primarily used to achieve counting. This type of device is capable of changing states when a pulse is applied,output pulse.There are several types of counters used in digital circuitry today.Probably the most common of these is the binary counter.This particular counter is designed to process two-state or binary information. J-K flip-flops are commonly used in binary counters.Refer now to the single J-K flip-flop of Fig. 3-11 .In its toggle state,this flip-flop is capable of achieving counting. First,assume that the flip-flop is in its reset state. This would cause Q to be 0 and Q to be 1 .Normally,we are concerned only with Q output in counting operations. The flip-flop is now connected for operation in the toggle mode. J and K must both be made the 1 state. When a pulse is applied to the T,or clock,input,Q changes to 1.This means that with one pulse applied,a 1 is generated in the output. The flip-flop the next pulse arrives,Q resets,or changes to 0. Essentially,this means that two input pulses produce only one output pulse. This is a divide-by-two function.For binary numbers,counting is achieved by a number of divide-by-two flip-flops.To count more than one pulse,additional flip-flops must be employed. For each flip-flop added to the counter,its capacity is increased by the power of 2. With one flip-flop the maximum count was 20,or 1 .For two flip-flops it would count two places,such as 20 and 21.This would reach a count of 3 or a binary number of 11.The count would be 00,01,10,and 11. The counter would then clear and return to 00. In effect, this counts four state changes. Three flip-flops would count three places,or 20,21,and 22.This would permit a total count of eight state changes.The binary values are 000,001,010,011,100,101,110 and 111.The maximum count is seven,or 111 .Four flip-flops would count four places,or 20,21,22,and 23.The total count would make 16 state changes. The maximum count would be 15,or the binary number 1111.Each additional flip-flop would cause this to increase one binary place.河南理工大学电气工程及其自动化专业中英双语对照翻译。